Engineering Services

Orana Engineering offers a complete range of engineering services and design drafting services through the in-house expertise of our qualified and experienced team. As an engineering consultancy working in mechanical, electrical, structural and control systems engineering, Orana Engineering is experienced in detailed design engineering for the coal mining, metalliferous mining, oil and gas and heavy industries.

Orana Engineering's engineering services include, but are not limited to the preparation and delivery of:

- Budget Estimates;

- Detailed Engineering Designs and Calculations;

- Engineering Investigations and Audits;

- Engineering Specifications;

- Engineering Studies;

- Functional Descriptions;

- Hazardous Area Designs;

- Project Management;

- Project Scheduling;

- Scopes of Works;

- System Modelling;

- Tailored Control System Training Courses; and

- Technical Evaluations.

For projects consisting of civil engineering design, Orana Engineering has the resources to fulfill the project's requirements via in-house expertise and established and proven relationships with external companies.

Our people are core to the quality of engineering services offered and our team is both technically qualified and practically experienced. Our staff possess RPEQ certifications, CPEng qualifications and hands-on site backgrounds. We deliver a unique approach to engineering services and engineering design. Having operations and maintenance engineering backgrounds, the experience of Orana Engineering personnel make them better able to understand the complexities and scheduling challenges that are often involved in performing engineering activities for continuous and remote operations. This results in a more cost and time efficient solution for the client.

The unique combination of our experience, wide-ranging capabilities and practical approach ensures Orana Engineering delivers engineering services that:

- Perform - Site experience and trade backgrounds mean our engineering designs are practical and considerate of site factors that can complicate a project, our designs are not just good on paper;

- Are simple - Our clients have access to a full range of engineering services under one roof, building a relationship with one engineering firm that can manage everything from your design drafting, drawing revisions and drawing management through to complete project management or Client Engineer assistance;

- Instill confidence - Working with an experienced firm gives our clients confidence and allows them to be informed to make decisions; and

- Are efficient - Outsourcing engineering services can assist with site resourcing, freeing up site personnel and ensuring that you have a qualified expert dedicating the right amount of time to the required task.

Contact us today to see how Orana Engineering’s qualified and experienced personnel can add value to all your engineering service requirements.

Orana Engineering Design Drafting

Onsite Accommodation Camp Services

Orana Engineering was engaged by Oaky Creek Coal to assist in design and construction of onsite camp accommodation, including an HV substation for power and potable water supply. Our brief included mechanical, electrical and control systems design, drafting and engineering for the project. Deliverables included scope of works, construction drawings, functional specification, drawing and equipment registers, commissioning and operating spares lists and equipment and instrument data sheets. Orana Engineering provided PLC configuration and commissioning assistance for pump control, acted as Client Representative during construction, managed onsite commissioning of the system, and provided a handover to operations for implementation. Operation & Maintenance Manuals for potable water storage and the HV substation were provided upon completion.

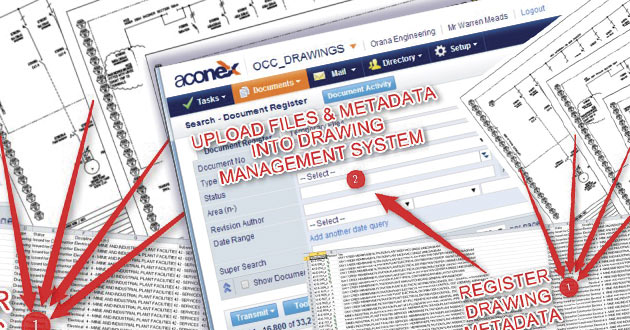

Read moreProcess Water RO Plant Vendor Drawing Registration

Following commissioning of their Process Water Reverse Osmosis (RO) Plant, Oaky Creek Coal received approximately 150 electrical drawings from the vendor. To provide site personnel with access to the drawings, Oaky Creek engaged Orana Engineering to register these within their existing drawing management system. There are many drawing management systems and tools on the market and Orana Engineering has the capabilities and resources to utilise whatever system is preferred by a client. Oaky Creek Coal sets a very high standard in the industry for the maintenance of drawings and in real terms realises the significant cost benefits that good drawing management delivers in enabling site personnel to perform effectively and safely.

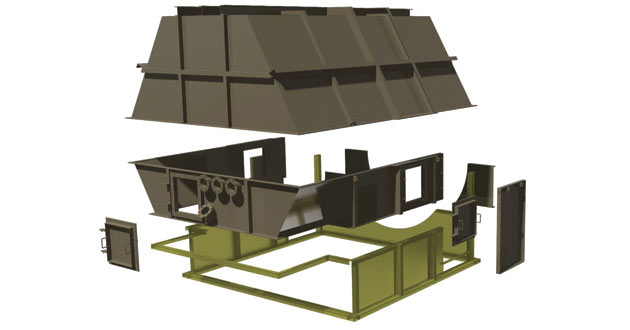

Read moreSAG Mill Cover

BHP Billiton Cannington Mine, is a significant miner and exporter of silver and lead concentrate. Orana Engineering was engaged to provide workshop fabrication drawings for a replacement cover to address corrosion issues around flanges and access openings on the existing SAG mill trommel sump cover. Following a site visit to obtain measurements, photos, drawings and documentation, the Orana Engineering design drafting team created a detailed 3D model of the existing structure incorporating new components to produce a set of detailed shop fabrication drawings while also revising multiple existing drawings. These drawings were reissued for construction after receiving client approval. The new cover sections and access panels improved the safety of trommel operation while also reducing inspection and maintenance time.

Read moreSewage Treatment Plant Refurbishment

To increase productivity and maintain compliance with legislative standards, Glencore Coal employed the services of Orana Engineering to design and manage the electrical aspects of an upgrade to their existing sewage treatment plant. The project was managed on-site by others, with Orana Engineering providing electrical engineering, design, project management and construction / commissioning assistance. Upon completion of installation, Orana Engineering updated all drawings to reflect any changes made, thus providing Glencore Coal with as-built drawings which will make any future maintenance or fault-finding work more efficient and cost effective, as well as providing legislative compliance.

Read moreSite DCS Support

The Coal Handling & Preparation Plant at Oaky Creek Coal utilises a Yokogawa Distributed Control System for control and monitoring of their operation. The system incorporates Yokogawa’s OPC server and Exaquantum data historian. OCC utilises multiple Programmable Logic Controllers for specific operational purposes, with a number of PLCs interfaced back to the DCS for control and monitoring functions. Since 2005, Orana Engineering has provided 24/7 support for Oaky Creek’s control system. Day to day support is provided by remote access, which is cost effective and highly responsive. Additionally, onsite support for hardware solutions and commissioning of larger projects is provided as required.

Read moreTank Farm Upgrade

Melbourne Bio Diesel’s James Cook University research facility required an elevated level area for installation of fresh sea water storage tanks. Orana Engineering was requested to design a solution that increased efficiency with tank drainage and improved safety around the tanks. A site visit was performed to gather measurements of the nominated tank farm area. This included identifying trees requiring removal and determining required tank heights and current ground levels. From the information gathered Orana Engineering used AutoCAD to model ground levels and the fill required to lift tanks to a suitable level for gravity drainage. The design incorporated a conical base on each tank for drainage and the introduction of buried control valves accessible via covered pits.

Read moreTank Static Line

Management at Carpentaria Gold’s Ravenswood Operation enlisted Orana Engineering to design a fall arrest system that could be easily removed and repositioned above multiple leach tanks, allowing for safe removal and servicing of tank agitators. From a site visit, Orana Engineering identified the need for an arrangement that could be easily disassembled and relocated to each leach tank. The design was challenging due to the varying nature of access structure members above tanks. Orana Engineering designers proposed an assembly utilising a common set of supporting columns with struts of varying lengths depending on the work location. A full set of shop fabrication and assembly drawings were issued with the final design providing safety for personnel working above open tanks.

Read moreTippler Refurbishment Feasibility

The Glencore Port Operations in Townsville operate an export facility for minerals concentrate and refined copper within the Port of Townsville precinct. The concentrate in-loading rotaside tippler was identified as being at end of life and a feasibility study was commissioned to review a like-for-like replacement option for refurbishment of the tippler. To facilitate feasibility-level costing, Orana Engineering was asked to provide electrical engineering and mechanical engineering assistance with provision of a concept design for the proposed refurbishment and upgrade. By working closely with Glencore, and other consultants engaged on the project, Orana Engineering was able to contribute as part of a collective "owners engineering team" to the feasibility assessment of a significant engineering project in the Townsville Region.

Read moreTK102 Bypass Piping

When tasked with a major repair to one of their leaching tanks, personnel at Carpentaria Gold, Ravenswood enlisted the assistance of Orana Engineering to develop a solution that would allow process operations to continue whilst leaching tank TK102 was out of service. A site visit and discussions with the client suggested a bypass line be installed around TK102. By utilising site information, Orana Engineering designers were able to detail a new bypass line through the existing processing plant area. This involved minor modification of existing structural steel and addition of pipe supports for the new HDPE bypass pipeline. Bypass piping was successfully installed during normal operation with only tie-ins needing to be installed during a single shut down.

Read moreTreated Water Boost Pumps

Oaky Creek Coal uses an onsite RO plant to provide treated recycled water to various site operations. An opportunity was identified to use this recycled water for supply to critical equipment such as horizontal belt filters. Improving the equipment water quality resulted in a reduction in equipment downtime and lowered maintenance requirements. Orana Engineering reviewed the performance of two existing boost pumps intended to provide high pressure treated water to a new HBF. Hydraulic modelling was performed to predict future demand and thus determine the suitability of the existing pumps for use in the new application. Orana Engineering also prepared a control philosophy for use by systems engineers to ensure safe operation of the pumps under all operating conditions.

Read more