Engineering Services

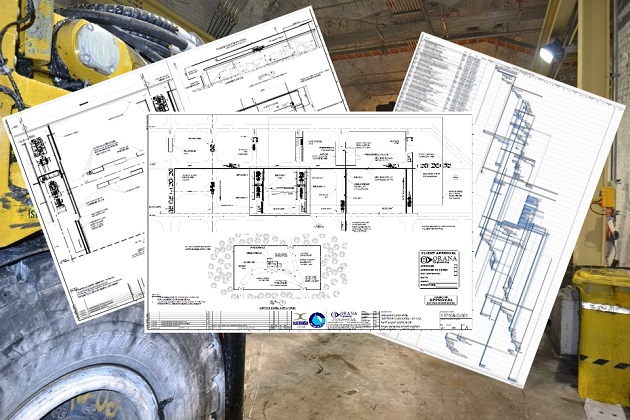

Orana Engineering offers a complete range of engineering services and design drafting services through the in-house expertise of our qualified and experienced team. As an engineering consultancy working in mechanical, electrical, structural and control systems engineering, Orana Engineering is experienced in detailed design engineering for the coal mining, metalliferous mining, oil and gas and heavy industries.

Orana Engineering's engineering services include, but are not limited to the preparation and delivery of:

- Budget Estimates;

- Detailed Engineering Designs and Calculations;

- Engineering Investigations and Audits;

- Engineering Specifications;

- Engineering Studies;

- Functional Descriptions;

- Hazardous Area Designs;

- Project Management;

- Project Scheduling;

- Scopes of Works;

- System Modelling;

- Tailored Control System Training Courses; and

- Technical Evaluations.

For projects consisting of civil engineering design, Orana Engineering has the resources to fulfill the project's requirements via in-house expertise and established and proven relationships with external companies.

Our people are core to the quality of engineering services offered and our team is both technically qualified and practically experienced. Our staff possess RPEQ certifications, CPEng qualifications and hands-on site backgrounds. We deliver a unique approach to engineering services and engineering design. Having operations and maintenance engineering backgrounds, the experience of Orana Engineering personnel make them better able to understand the complexities and scheduling challenges that are often involved in performing engineering activities for continuous and remote operations. This results in a more cost and time efficient solution for the client.

The unique combination of our experience, wide-ranging capabilities and practical approach ensures Orana Engineering delivers engineering services that:

- Perform - Site experience and trade backgrounds mean our engineering designs are practical and considerate of site factors that can complicate a project, our designs are not just good on paper;

- Are simple - Our clients have access to a full range of engineering services under one roof, building a relationship with one engineering firm that can manage everything from your design drafting, drawing revisions and drawing management through to complete project management or Client Engineer assistance;

- Instill confidence - Working with an experienced firm gives our clients confidence and allows them to be informed to make decisions; and

- Are efficient - Outsourcing engineering services can assist with site resourcing, freeing up site personnel and ensuring that you have a qualified expert dedicating the right amount of time to the required task.

Contact us today to see how Orana Engineering’s qualified and experienced personnel can add value to all your engineering service requirements.

Orana Engineering Design Drafting

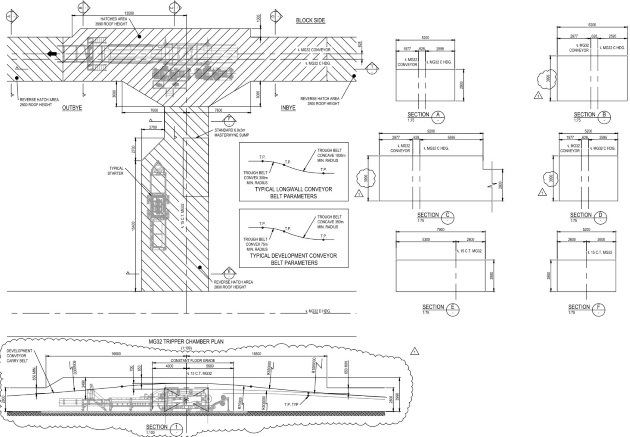

UG Conveyor Installations – MG32 Tripper Chamber

At Glencore’s Oaky No.1 underground coal mine, transportation of vast quantities of coal over long distances requires significant power. Often drive-head power is insufficient or constrained by allowable belt tension and an additional drive/power source is required to meet operating capacity. Additional power is commonly sourced from a driven conveyor tripper installed along the conveyor with appropriate excavation for the tripper. Using the client’s existing mine plan to position the new tripper chamber, Orana Engineering design drafting personnel worked with site engineers to assess required chamber dimensions while simultaneously minimising the excavation of material. Orana Engineering used AutoCAD to produce a drawing set detailing the mining required, and an overlay showing future equipment installations within the new chamber.

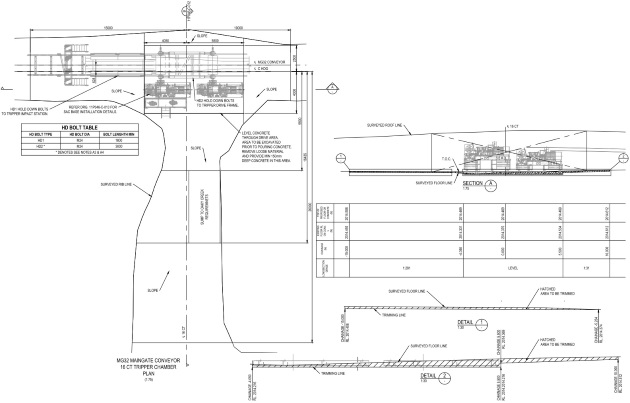

Read moreUG Conveyor Installations – MG32 Tripper Civil Design

Engineers at Glencore’s Oaky No. 1 underground coal mine engaged Orana Engineering to determine civil work requirements to install tripper equipment on the MG32 longwall conveyor. On completion of chamber mining, finished surfaces (rib and floor) may require modification for the installation of conveyor tripper equipment. The civil design must determine concrete grades for drainage, safe access and reinforcing for conveyor equipment, while minimising trimming and concrete required. Manipulating “as-cut” survey data using AutoCAD, Orana Engineering design staff could accurately determine where tripper equipment could be installed with minimal trimming and concreting. A drawing set was produced detailing civil aspects of the tripper design, including chamber trimming, equipment mounting locations, configuration of reinforcing and relative concrete levels for drainage.

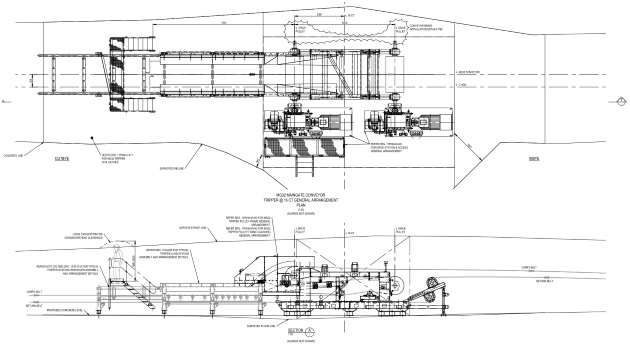

Read moreUG Conveyor Installations – MG32 Tripper Mechanical Design

Orana Engineering was engaged by Glencore to design and install a detailed arrangement of tripper drives, brakes, pulley frame and load station for the MG32 conveyor at its Oaky No.1 underground coal mine. Mechanical design considerations included operating capabilities, unimpeded travel road access and minimum belt curves. The design was dependent on the civil installation previously detailed by Orana Engineering. Often equipment is simply re-located from previous installations with minor modifications. Orana Engineering has developed unique methods for completing this type of design efficiently and at reduced cost to our clients. AutoCAD was used to develop a mechanical design, from which a drawing set was produced that detailed out the mechanical aspects of the tripper installation

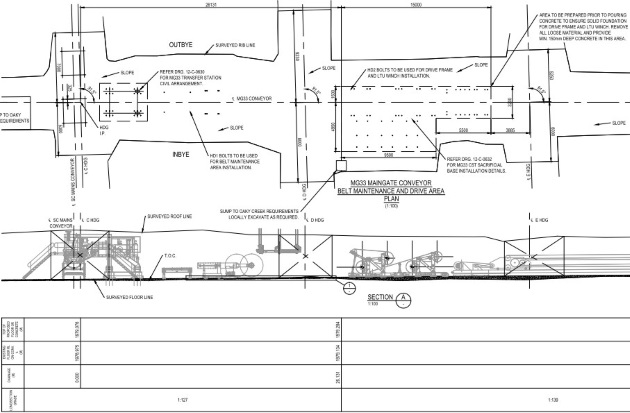

Read moreUG Conveyor Installations - MG Civil Installation

Engineers at Glencore’s Oaky No. 1 underground coal mine engaged Orana Engineering to determine civil work requirements to effectively utilise drive-head equipment in newly mined chambers for conveyor installations. On completion of chamber mining, finished surfaces (rib and floor) may require modification for installation of the conveyor drive-head equipment. The civil design must determine concrete grades for drainage, safe access and reinforcing for conveyor equipment, while minimising trimming and concrete required. Manipulating “as-cut” survey data using AutoCAD, Orana Engineering design staff could accurately determine where equipment might be installed with minimal trimming and concreting. A drawing set was produced detailing civil aspects of the conveyor design, including chamber trimming, equipment mounting locations, configuration of reinforcing and relative concrete levels.

Read moreUnderground Workshop Concept Design

Due to expanding operations, Oaky North underground operations saw benefit in having an underground workshop and refuelling stations to reduce vehicle travel times and increase efficiencies. Orana Engineering was engaged to provide concept design and estimating assistance for project approval. From communications with our client, Orana Engineering prepared concept general arrangement drawings for consideration. Based on these concept design drawings, a project capital estimate and project schedule were prepared for Oaky North underground operations. From the information presented by Orana Engineering, Oaky North could accurately consider whether the underground workshop was feasible, and ensure that appropriate budgets and project planning was completed at the concept design phase to improve confidence in the project prior to execution.

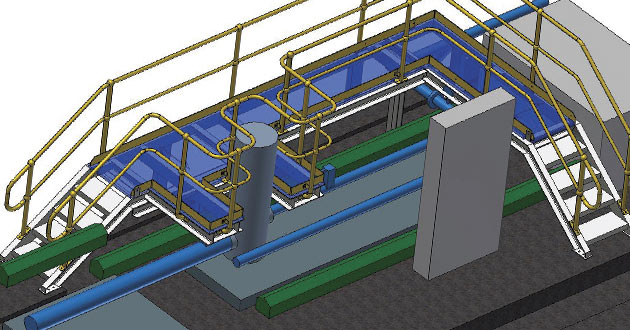

Read moreWater Polishing Plant Access Platform

BHPB Cannington’s Port Storage Facility operates a water polishing plant for treatment of stored water. The system requires regular maintenance for replacement of plant filtration rods, however with maintenance ports inaccessible from the ground, work platforms had to be arranged. To simplify this task and improve safety, BHPB Cannington identified the need for a permanent access platform. Orana Engineering was engaged to design a platform that allowed easy access to the maintenance port, while ensuring access to existing services was not compromised. Orana Engineering utilised AutoDesk Inventor to model a platform that would not impact on the existing structure, services or access routes while ensuring safety for maintenance workers. Following model verification, shop detail fabrication drawings were produced.

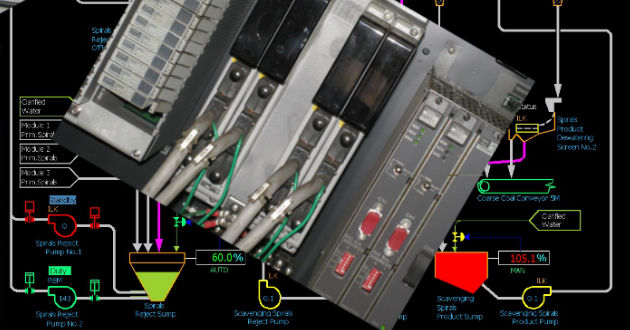

Read moreYokogawa DCS Upgrade

Since 2005, Orana Engineering has provided 24/7 support for Oaky Creek Coal control systems. At the coal handling and preparation plant, a Yokogawa DCS installed in 1998, is used as the primary control system. With existing CentumCS Unix software no longer supported by Yokogawa, it was essential to complete an upgrade to the CentumCS3000 system. Orana Engineering developed conversion tools to allow configuration data to be extracted from the CentumCS Unix platform and imported into the CentumCS3000 environment. These tools provided efficiency and accuracy for the conversion and delivered a significant cost saving. The quality of conversion tools and simulation programs developed by Orana Engineering resulted in highly efficient site commissioning, completed without plant downtime.

Read more