Electrical Engineering Consultants

Electrical energy is extremely efficient to store and easy to transfer and as a result is most commonly used throughout the world for the operation of devices and equipment. In addition to operating mechanical systems, electricity is also used as an energy source for chemical processes (e.g. refining), thermal processes (e.g. smelting) and electronic systems.

The field of Electrical Engineering covers the design, installation, operation and management of electrical distribution and electrical storage systems. It relates to the safe, efficient and reliable transfer (i.e. supply) of electrical energy to power equipment and systems that are used within an operating plant or site. Electrical Engineering is also designing the transmission and distribution of power for systems such as instrumentation and control systems, electrical plant and equipment as well as communications networks.

Orana Engineering is experienced with the Electrical Engineering of both LV (Low Voltage) and HV (High Voltage) systems and has the capabilities and resources to provide engineering services for:

- Power system modeling, inclusive of HV system fault studies, protection studies, load studies, arc flash studies and harmonic analysis;

- Substation transformer, switchgear and earthing system designs;

- Motor control centre and distribution board designs;

- Power factor correction system designs;

- Electrical drive system designs (soft starter, variable speed, autotransformer, resistance)

- Electrical control system designs (hardwired and automation control systems);

- Hazardous area designs;

- Lightning protection system designs;

- Instrumentation system designs;

- Commissioning of electrical and instrumentation systems; and

- Earthing designs.

We provide specialist Electrical Engineering services to coal, metalliferous, oil and gas clients as well as industrial and commercial clients. Explore the case studies below for more information on Electrical Engineering services by Orana Engineering.

Orana Engineering Electrical Engineering

Village Kitchen Upgrade

The Village Kitchen at Glencore’s Hail Creek Mine camp was scheduled for upgrade with Orana Engineering engaged to provide engineering support for electrical, civil and building works, including a new shed. A site visit was conducted to determine the scope of the upgrade and to collect site information comprising photos, drawings, measurements and location of water and gas services.

From the information gathered, Orana Engineering provided engineering design and project management of the Village Kitchen upgrade including a new shed distribution board, concrete slab, layout and connection of services to the new shed and prepared a detailed scope of work document for tendering purposes.

Orana Engineering design drafters produced RPEQ certified GA and concrete drawings showing details of services to be relocated, a slab and loading dock drawing, a new single line diagram for the distribution board, and revisions to existing distribution board drawings.

Rajant Network

Glencore planned to install the CAT MineStar Terrain Office system at its Oaky Creek Coal Mine to support GPS positioning and live maps in CHPP stockpile dozers. As part of the upgrade, mine infrastructure and dozers required hardware installation to connect the dozers to the site network and enable communication with MineStar servers. In line with other Glencore sites, it was chosen to implement a Rajant wireless network to cover stockpiles and provide connectivity between dozers and the network.

Orana Engineering was engaged to provide electrical and Operational Technology (OT) engineering design, configuration and drafting support for the CAT MineStar GPS implementation including preparation of three new virtual servers for various applications. Orana Engineering electrical engineers developed a scope of work which provided an overview of the onsite electrical installation works required to be carried out by others with supply, installation, testing and commissioning project managed by an Orana Engineering electrical and control systems engineer.

C22147 Water Destruction

Glencore’s Collinsville Open Cut mine utilises sprinklers to partially destroy Acid Mine Drainage (AMD) water generated. Existing sprinklers were effectively moving the AMD water, but at a slow rate. Orana Engineering was contacted for assistance in designing a system to increase the existing sprinkler arrangement from 67 to 200 units, capable of dewatering up to 9.45ML per day, while utilising a minimum of pumps and nozzles.

Orana Engineering mechanical and electrical engineers gathered data and undertook hydraulic modelling in developing a sprinkler design to increase water surface area while decreasing maintenance and failure rates of existing nozzles.

3D modelling of the design was presented to the client along with RPEQ supevised detail design drawings.

Sewage Treatment Plant Concrete Slab

CS Energy engaged Orana Engineering to provide engineering and drafting support in documenting the scope for onsite civil, electrical (earthing) and mechanical (shade sail and drain piping) supply and installation at its Kogan Creek Power Stations Sewage Treatment Plant.

The basis of design was provision of detailed design engineering of a bunded concrete slab to house two 22kL aerated tanks and a 20 foot container. The slab design was to include an effluent drainage system with a new discharge pipe to be connected to the existing underground wastewater drainage network. It was planned to remove existing tanks and pumps and the design scope prepared by Orana Engineering was to include details for filling and capping the residual drainage pipes and holes.

Design drawings generated by Orana Engineering personnel to support the scope of work included a general arrangement, a detailed drawing and a revised layout drawing.

.jpg)

Oily Water Pond

Origin Energy’s Talinga Gas Plant oily water system treats water created during the gas compression process. Effluent from the system is pumped into the water-gathering network, delivering water to the main water treatment plant.

Orana Engineering was engaged by Origin Energy to evaluate the oily water system and conducted a high level assessment of options to reduce the risk of uncontrolled release of contaminated water from the wetlands system that was controlled by interim means.

Outcomes were presented to the client summarising options to reduce or eliminate identified risks. Orana Engineering subsequently provided detailed mechanical and electrical design and drafting for the approved option.

Deliverables for the project included a basis of design document, detailed design and a revison of the Wetland Operations & Maintenance Manual.

HV Tripping Supplies

Incitec Pivot’s Phosphate Hill site required replacement of tripping supplies for HV switchboards within its Ammonia Plant, Central Services, Phosphoric Acid Plant, Granulation Plant and Beneficiation Plant.

The switchboards had a dedicated 110VDC tripping supply with battery backup to power the HV protection relays and provide tripping supply power to HV circuit breakers. Without this back-up supply, circuit breakers would not open in the event of an electrical fault which could result in a catastrophic switchroom fire.

Existing tripping supplies were approaching end of life and with component failure likely to increase it was proposed to replace the tripping supplies during suitable shutdowns.

Orana Engineering was engaged to complete engineering design and to provide design drawings ‘issued for construction’. The Orana Engineering-assigned project manager had responsibility for vendor engagement, liaison with site planning and procurement personnel and site attendance during installation, commissioning and construction stages.

Acid Unloading Leak Detection & CCTV Upgrade

To reduce the likelihood of potential spills in the sulphuric acid unloading area at its Phosphate Hill site, and to prevent consequential environmental and health and safety impacts, Incitec Pivot sought assistance from Orana Engineering with an upgrade of existing acid unloading leak detection and CCTV systems.

In consultation with Phosphate Hill site stakeholder personnel, Orana Engineering conducted an evaluation of available mitigation scenarios before recommending electrical and control methods which were considered to be the most cost effective resolution. Orana Engineering drafting personnel also produced detailed design drawings for the acid unloading leak detection and CCTV upgrade works.

Airport Lighting

Incitec Pivot’s Phosphate Hill site contacted Orana Engineering to request assistance with evaluation of its Monument Aerodrome runway and apron lighting system following a review of potential electrical hazards.

An assessment of the airport lighting installation was undertaken by Orana Engineering electrical engineering personnel with findings presented to the client in report format. Review considerations included reference to CASA and Australian Standards and outlined a high level risk assessment conducted to quantify electrical safety risks.

Following client consideration of recommendations, Orana Engineering provided front end loading (FEL 3) documentation for replacement of existing runway and taxiway lights, series isolation transformers and the existing lighting control system. A scope of work was then prepared with the tender process managed by Orana Engineering on behalf of the client for the appointment of a specialist airport lighting contractor to complete design and construction of the lighting and control system upgrades.

_1.webp)

Terminal Dam MCC

The Terminal Dam pump station at Glencore’s Oaky Creek coal mine is critical in supplying the mine and township of Tieri with raw water. The existing pump station had been in service for over 30 years during which time the electrical reticulation equipment had regular maintenance but no significant upgrades. Obsolete components, changes in Standards and degradation of the equipment all signaled that the HV supply, LV MCC and LCU’s was apporaching its end of service.

At the request of Oaky Creek Coal, Orana Engineering undertook offsite electrical and control system engineering and design drafting for a Terminal Dam HV upgrade and MCC replacement. An update of the Electrical Installation SOW for the modification at Terminal Dam was prepared prior to attending site to complete the configuration and assist with project management of installation and commissioning works.

Precipitator Controllers

Incitec Pivot contacted Orana Engineering for assistance in identifying options for upgrading its Mount Isa Acid Plant Electrostatic Mist Precipitators (EMP). This was primarily to mitigate issues with EMP 7 and 8 which were contributing to low dust capture efficiencies, converter catalyst degradation and potentially premature damage to tube bundles.

Orana Engineering electrical engineering personnel sourced additional information on issues experienced and liaised with equipment manufacturers for recommended solutions. A design review table was prepared to summarise and document data from previous reviews including reports, tests, inspections and previous recommendations.

Orana Engineering provided offsite assistance in co-ordinating procurement and installation with deliverables to the client comprising the finalised design review summary table, BOM, equipment quotes and redline drawing mark-ups for upgrade of the EMP controller.

Package Boiler Replacement

Package boilers at Incitec Pivot’s Phosphate Hill mine were unserviceable to operating challenges. To compensate, low pressure steam supply was being supplemented from the power station. Phosphate Hill required return of the low pressure steam supply to site and back to full reliability to allow improved steam export to its Phos Acid Evaporation Circuit.

The new boiler was to be a 10MW unit with an automated water treatment system to maintain correct chemical dosing rates and reduce corrosion, thereby improving long term reliability.

The scope of Orana Engineering’s engagement was provision of electrical engineering site assistance associated with replacement of the existing package boiler for new, replacement of boiler feedwater pumps, combustion air fan and control panel. Additionally, automation of the chemical dosing system, instrument replacements, co-ordination of Type B gas appliance approvals and commissioning was provided.

.jpg)

HA Reclassification

Origin Energy’s Mount Stuart Power Station operated three power turbines driven by aviation kerosene and consideration was being given to converting these to operate on an alternative fuel source. Orana Engineering was engaged to conduct a hazardous area classification assessment covering re-classification of site areas relevant to the fuel conversion and to address handling of flammable gases produced as part of normal plant operation.

The objective was to establish whether an explosive atmosphere would exist around equipment following the proposed fuel conversion and to verify the classification and extent of hazardous areas in line with regulatory guidelines and standards AS 60079 Series and IE Model Code of Safe Practice, Part 15.

Upon conclusion of Orana Engineering’s assessment, the client was provided with a comprehensive Hazardous Area (HA) Classification Report confirming that ventilation at the plant was deemed adequate due to the outdoor location of most equipment and artificial ventilation within turbine and pump enclosures. Revised HA area classification drawings were also provided by Orana Engineering drafting personnel.

Brine Concentrator Drain Pump System

Orana Engineering was invited by MFE to provide an estimate for subcontract works for the Veolia Water brine concentrator drain pump system at Kenya Water Treatment Plant.

Brine concentrators at the plant periodically release high temperature and corrosive wastewater to floor sumps to control or monitor processes. The PVC pipework from floor sumps had become unserviceable due to the pipeline material not being rated for high temperatures. The existing drainage pipeline needed to be replaced with a durable system capable of withstanding high temperature corrosive wastewater.

Orana Engineering’s involvement in the project encompassed provision of engineering support (hydraulic, mechanical, civil and electrical design) and drafting support including revision of existing drawings and generation of new hydraulic, mechanical, civil and structural drawings with RPEQ supervision.

Fire Pumps Automation

The main plant raw water boost pumps at Glencore’s Oaky Creek Coal were supplied via a starter panel which required replacement due to water inundation and for improved functionality, reliability and compliance.

At the client’s request, Orana Engineering provided a report outlining preliminary design checks completed and provided a high-level summary of installation works required to the pump starter panel for a new MCC already on site.

Multiple upgrades were required to electrical equipment as well as associated civil / structural works. A preliminary concept sketch was prepared giving an overview of proposed upgrades. An Orana Engineering Electrical Engineer was appointed to assist with onsite commissioning of the raw water boost pumps and to provide offsite assistance with DCS configuration.

Deliverables to the client included electrical engineering and design drawings to IFA/IFC, a scope of work and a bill of materials.

Main Sub Upgrades

The main substation at Glencore’s Oaky Creek Coal is essential for surface operations. Site personnel had highlighted multiple projects for implementation to collectively improve the integrity and reliability of the main sub. For each of the projects there were common elements and beneficial outcomes for executing them concurrently.

Given the critical nature of the projects and the importance of success, Orana Engineering developed a project management and design scope for provision of a dedicated Electrical / Control Systems Engineer from its Engineering Team.

Projects under the scope consisted of safety and reliability upgrades for OCC Main 66 / 11kV substation including automated racking of circuit breakers, interlocking of transformer tap changers and parallelling control, cable pit sump pump control.

Work undertaken included detailed design, PLC and DCS configuration, protection relay configuration, racking controllers, and commissioning whilst also mananging the client's drawing management system.

Orana 4 Pump Station

Veolia Water engaged Orana Engineering to look into options for a replacement pump station at its QGC Kenya Central Water Treatment Facility.

High level concept design investigations were initiated for options to replace the existing diesel driven manually controlled pump system for transferring brine from the site's Orana 4 Pond to the plant for treatment. Both a land based primed pump station and a water based floating pump station were given high level consideration. A detailed concept options report was developed for review and consideration by site stakeholders.

Cable Failure Investigation

MMG’s Dugald River Mine in north-west Queensland had experienced issues with LV cables feeding large MCCs on site. Following damage to a cable, gland and gland plate within the Flotation Area MCC, Orana Engineering was engaged to conduct an investigation into the cause.

The faulted cable and two un-faulted cables from the same MCC incomer were transported to Orana Engineering’s Townsville office where they were inspected, dismantled, measured and photographed. A review of site data was carried out with conclusions indicating the most likely cause of failure was degradation of cable insulation due to heat generated at the cable gland by a circulating current in the armour of the single core cable.

Orana Engineering’s findings and methods for preventing similar occurrences were presented to the client in report format at the conclusion of the investigation.

Ash Water Treatment Plant

CSE Energy’s Kogan Creek Power Station identified that due to higher than normal rainfall its decant pond had neared capacity and was unlikely to evaporate in an acceptable timeframe by either natural means or with the assistance of fans. It was proposed to reuse the water on site, however due to a concentration of suspended silt the decant water required treatment before being returned to the plant. The solution was sourcing and installation of a containerised water clarification plant.

Orana Engineering was contacted for provision of electrical engineering design and support for power and control of the proposed ash water treatment facility as well as mechanical engineering input with pumping, piping and tank design for water supply and tie-in to existing infrastructure.

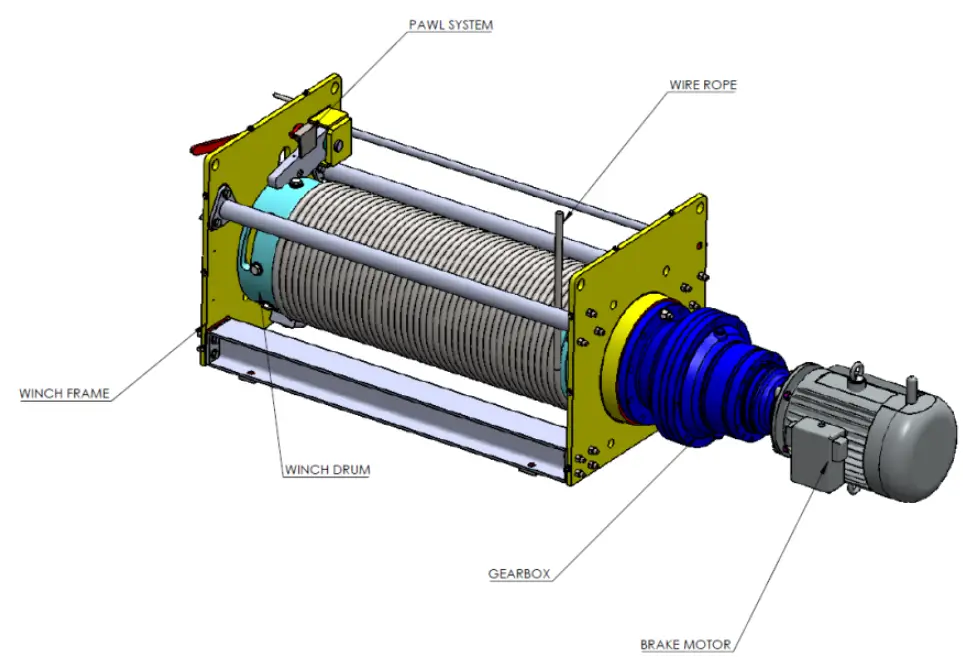

Conveyor Counterweight Design

Orana Engineering was approached by Glencore’s Oaky Creek Coal CHPP personnel to supply a cost estimate for development of modified winch systems for its CV15 and CV16 take-up towers.

The scope of work included provision of mechanical, structural and electrical engineering and design drafting for inclusion of electric take-up winches to facilitate lowering of conveyor counterweights during maintenance activities.

Structural and civil checks were conducted to account for expected force changes caused by additional sheaves and electrically driven winching effects on the structures when compared to the existing gravity take-up applications. The installation was configured and commissioned into the DCS control system by Orana Engineering's control systems engineers.

In addition to mechanical and electrical detailed design drawings, Orana Engineering provided equipment recommendations and specifications, bill of materials and a Safety In Design Report upon finalisation of the design development cost estimate.

Reagents Tank Farm Rectification

Due to the existing system not being compliant to site standards, BMA Saraji Mine had constructed a new reagents system for the supply of diesel and MIBC into their CHPP. Following construction, several attempts were made to wet commission the system however these were unsuccessful due to multiple problems identified by the client.

Orana Engineering was requested to undertake a complete design review of the reagents system, to outline problems with the design and to provide a scope of work to rectify these such that wet commissioning could be completed.

At the conclusion of the review a bill of materials for the commissioning scope of work was provided, detailing procurement specifications for required mechanical equipment and spares.

PPP027 Plant Feed Upgrade

Century Mining’s zinc tailings treatment operation is situated in north-west Queensland and is the largest tailings retreatment operation in Australia. Century sought the services of Orana Engineering in providing engineering support for its PPP027 Plant Feed Upgrade Project.

The project scope encompassed multidisipline engineering design for the upgraded plant feed pumping system including Weir Warman pumps. The client also requested a mechanical engineering review into combined use of poly lined, rubber lined and UHMWPE piping supported by Orana Engineering’s liaison with product vendors. Electrical design and site based support was delivered by Orana Engineering to suit the requirement of the project resources and timeline. Civil and structural engineering design was completed for the underground services and concreted area and footings.

.webp)

APA Group Tender

APA Group released a project for tender comprising electrical and instrumentation for rectification of hazardous area compliance issues. Condamine Electric Company (CEC) tendered on the work and engaged Orana Engineering to prepare a detailed estimate of costs to complete the rectification works.

Orana Engineering undertook a detailed review of the scope and drawings in the tender package to ascertain requirements. Quotes for non-standard equipment were obtained and a detailed cost estimate was created. Additionally, from the scope review Orana Engineering identified and compiled a comprehensive list of questions which were subsequently raised by CEC during a tender site visit. Upon provision of responses, Orana Engineering delivered a complete capital estimate to CEC for tendering.

Combabula Bore Pump

Prime Pump Company was contracted by Origin Energy and Laing O’Rourke to supply an upgraded bore pumping system at Origin’s Combabula site. RIE Services was contracted by Prime Pump Company to supply and install electrical components for the upgrade, with Orana Engineering subsequently engaged by RIE Services to complete a fault protection study on the new installation.

Using SKM Power Tools for Windows software and manual calculation techniques for verification, together with information from RIE and Prime Pump Company, Orana Engineering produced an HV/LV model calculating fault levels and completing a protection co-ordination study.

From the study it was recommended a new circuit breaker be introduced to protect the transformer, variable speed drive and supply cables.

10M TAGS Sled

At James Cook University, MBD Energy operates a research facility investigating methods of cultivating and harvesting algae. To facilitate greater control of the algae agitation sleds, Orana Engineering was engaged to design and commission mechanical, electrical and control systems that would enable agitation sled velocity and frequency of travel to be automated.

The system was designed and implemented by Orana Engineering utilising Allen Bradley Powerflex VVVF drives and a Controllogix’s PLC with an RSView SCADA interface.

Orana Engineering was able to help MBD Energy improve the efficiency and quality of their research results by providing technical knowledge and assistance through our control systems, electrical engineering and mechanical engineering services.

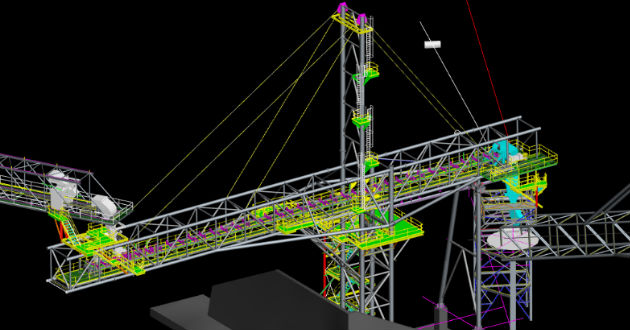

22M Flyover Conveyor

Oaky Creek Coal engaged Orana Engineering to perform electrical and control system design aspects of a 22M Flyover Conveyor to provide an interface between two existing conveyor systems.

Orana Engineering’s brownfield engineering expertise was drawn upon to resolve complexities in interfacing two different coal streams, powered from separate substations and controlled from independent process control systems. Should one system need to be shutdown it was necessary that the other system was not impacted.

The electrical engineering scope included powering the conveyor and transfer systems and providing lighting designs and power distribution. Control system engineering included selection and specification of instrumentation, specification of control system hardware and development of a functional specification.

CHPP Conveyor Capacity Audit

Vale at Carborough Downs Coal Mine required quantifying of current and possible future capacities of product conveyors at their coal processing plant in Central Queensland and high level recommendations to achieve increased plant tonnages.

Orana Engineering completed an initial site visit to gather the necessary information for a review of each of the conveyors. Engineering checks were completed to identify bottle-necks in the conveyor design such as motor power, drive equipment, belt curves, GTU mass, belt speed, belt capacity, belt tensions and electrical supply.

Orana Engineering issued a detailed report at completion of the study and provided concept level equipment modification recommendations for tonnage ranges advised by Carborough Downs Coal Mine.

Electrical Specifications

For site consistency of electrical design and installation standards and compliance with Australian standards and legislation, Glencore Oaky Creek Coal engaged Orana Engineering to prepare new site electrical specifications. The scope combined existing site specifications and practices and, where applicable, incorporated them into the new specifications. These specifications included:

- Electrical Design

- Electrical Installation

- Preferred Electrical Equipment List

- Site Equipment Numbering

- Drawing Management

Orana Engineering’s extensive knowledge of Queensland mine sites and long-standing experience at Oaky Creek enabled specifications to be produced cost effectively and fully inclusive of site specific details. Orana Engineering continues to maintain these documents for Oaky Creek Coal, ensuring that latest versions are readily available to site personnel via Oaky Creek’s drawing management system.

Flotation Cell Upgrade

To increase the efficiency of their concentrator, Eloise Copper Mine enlisted Orana Engineering to provide engineering and design assistance with installation of three copper concentrate scavenger cells within the existing plant.

3D models created by Orana Engineering designers were used to visually communicate solutions for new and existing equipment locations and structure arrangements. Detailing of these concept models enabled Orana Engineering to identify key tie-in locations within the plant for survey during the detailed design phase.

A multidisciplinary approach during detailed design ensured improved efficiency, with brownfield engineering challenges in relocating / connecting to existing equipment successfully achieved. Upon design completion the client was provided with an installation drawing set and scope of work.

MIBC & Diesel Upgrade

The purpose of the Reagent System Upgrade at Oaky Creek was installation of new reagent storage tanks, discharge / delivery pumping systems and automated flow control distribution manifolds for the delivery of each reagent to the nominated process connections.

Orana Engineering performed mechanical, electrical and control systems design, drafting and engineering for the project. The primary deliverables included scope of works, construction drawings, functional specification, BOM, spares lists and equipment / instrument data sheets.

Orana Engineering managed the onsite commissioning of the system and provided a system handover to operations for implementation. An Operation & Maintenance Manual and Hazardous Area Dossier were provided on project completion.

Mobile Plant Electrical Drawing Books

For personnel safety and compliance with Queensland’s Coal Mining Safety & Health Regulation it is a requirement for mine sites to provide electrical workers with access to up-to-date drawings for electrical equipment and electrical installations.

To improve the maintainability of plant electrical systems and personnel safety, Hail Creek Mine engaged Orana Engineering to create bound books of electrical drawings for Draglines 1 and 7 and Shovel 14. Multiple books were made for each machine in both A4 and A3 sizes and using waxed (waterproof) paper to ensure longevity.

Using vendor drawings from the client, Orana Engineering produced bound books containing all electrical power, control and termination diagrams associated with the respective mobile plant.

Onsite Accommodation Camp Services

Orana Engineering was engaged by Oaky Creek Coal to assist in design and construction of onsite camp accommodation, including an HV substation for power and potable water supply.

The brief included mechanical, electrical and control systems design, drafting and engineering for the project. Deliverables included scope of works, construction drawings, functional specification, drawing and equipment registers, commissioning and operating spares lists and equipment and instrument data sheets.

Orana Engineering provided PLC configuration and commissioning assistance for pump control, acted as Client Representative during construction, managed onsite commissioning of the system, and provided a handover to operations for implementation.

Operation & Maintenance Manuals for potable water storage and the HV substation were provided upon completion.

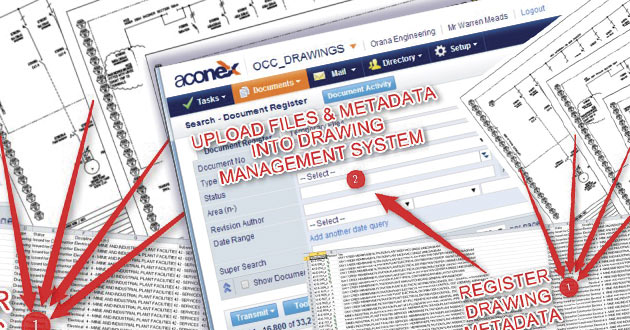

Process Water RO Plant Vendor Drawing Registration

Following commissioning of their Process Water Reverse Osmosis (RO) Plant, Oaky Creek Coal received approximately 150 electrical drawings from the vendor. To provide site personnel with access to the drawings, Oaky Creek engaged Orana Engineering to register these within their existing drawing management system.

There are many drawing management systems and tools on the market and Orana Engineering has the capabilities and resources to utilise whatever system is preferred by a client. Oaky Creek Coal sets a very high standard in the industry for the maintenance of drawings and in real terms realises the significant cost benefits that good drawing management delivers in enabling site personnel to perform effectively and safely.

Reagents Lightning Protection

To ensure the CHPP reagent tank farm lighting protection systems complied with Australian Standards, Moranbah North Coal requested Orana Engineering to undertake a review and design an upgrade of the lightning protection systems for the tank farm area.

With the area encompassing fuel storage tanks, it was classified as having structures with "explosive or highly flammable contents" and was therefore required to comply with AS1768:2008 Lightning Protection. Orana Engineering’s audit of the installation and its lightning protection systems confirmed that an upgrade of the facility was needed to comply with current lightning protection standards.

Utilising its team of detailed drafters Orana Engineering created a set of drawings detailing the work required to comply with AS1768:2008 Lightning Protection.

Redraw Dragline DL007 Drawings

To improve the maintainability of plant electrical systems and personnel safety, Hail Creek Mine employed the drawing revision services of Orana Engineering to redraw electrical power, control and termination diagrams associated with its Dragline 7 into AutoCAD format.

Having electrical drawings in CAD (computer aided design) format, is one of the most efficient ways to capture site electrical modifications, installations or as-building changes for ready access by site personnel involved in maintenance and operations.

Working closely with site contacts and onsite electricians, Orana Engineering was able to accurately reproduce 247 electrical drawings into AutoCAD for Dragline 7.

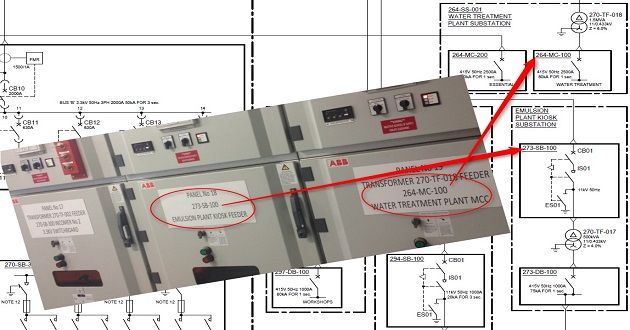

Redraw Electrical Drawings

To ensure plant maintainability and personnel safety, Dyno Nobel employed Orana Engineering to redraw its low voltage and high voltage single line diagrams, while also confirming their accuracy and functionality.

Through the use of client photos, documentation and discussions Orana Engineering was able to accurately redraw 52 low voltage single line diagrams as well as 6 high voltage single line diagrams.

During the redraw process Orana Engineering identified that a larger size drawing template was required to ensure critical information was easily readable on a single drawing. An A0 size drawing template was designed to meet Dyno Nobel's drawing standards with the template providing links for the document management system to easily access drawing metadata.

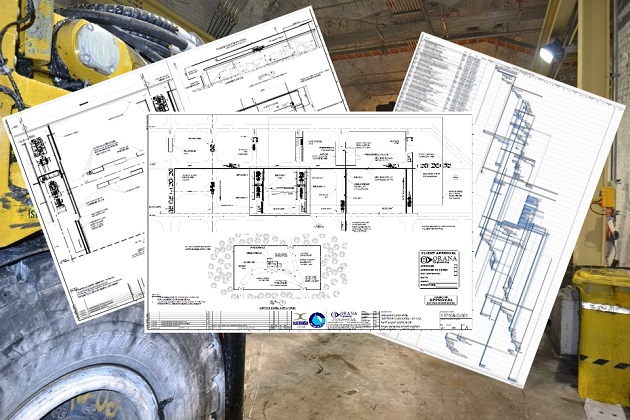

Sewage Treatment Plant Refurbishment

To increase productivity and maintain compliance with legislative standards, Glencore Oaky Creek Coal employed the services of Orana Engineering to design and manage the electrical aspects of an upgrade to their existing sewage treatment plant.

The project was managed on-site by others, with Orana Engineering providing electrical engineering, design, project management and construction / commissioning assistance.

Upon completion of installation, Orana Engineering updated all drawings to reflect any changes made, thus providing Glencore Coal with as-built drawings which will make any future maintenance or fault-finding work more efficient and cost effective, as well as providing legislative compliance.

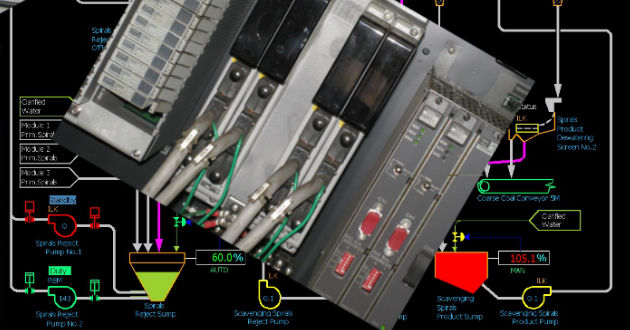

Site DCS Support

The CHPP at Oaky Creek Coal utilises a Yokogawa Distributed Control System for control and monitoring of their operation. The system incorporates Yokogawa’s OPC server and Exaquantum data historian. OCC utilises multiple Programmable Logic Controllers for specific operational purposes, with a number of PLC's interfaced back to the DCS for control and monitoring functions.

Since 2005, Orana Engineering has provided 24/7 support for Oaky Creek’s control system. Day to day support is provided by remote access, which is cost effective and highly responsive. Additionally, onsite support for hardware solutions and commissioning of larger projects is provided as required.

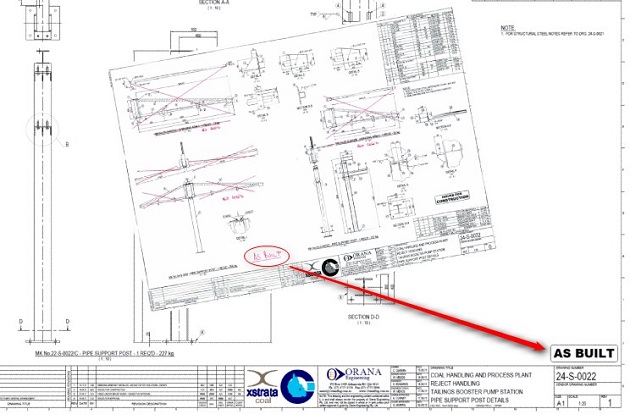

Tailings Pumping System - As-Built

At the completion of tailings pumping upgrades of the main CHPP and Module 4 CHPP at Oaky Creek Coal, Orana Engineering received as built drawings from site and was requested to make electronic revisions for upload into the client’s Drawing Management System.

Over 80 drawings had received red pen site mark-ups indicating either that the design had been constructed as per the drawings, or highlighting design changes made during the construction phase of the project. Orana Engineering reviewed these mark-ups and formally revised all drawings to as built status, incorporating the site mark-ups.

The final set of drawings was uploaded to the client’s Drawing Management System ensuring site personnel had access to the latest as built drawings.

Tippler Refurbishment Feasibility

Glencore Port Operations in Townsville operate an export facility for minerals concentrate and refined copper within the Port of Townsville precinct. The concentrate in-loading rotaside tippler was identified as being at end of life and a feasibility study was commissioned to review a like-for-like replacement option for refurbishment of the tippler.

To facilitate feasibility-level costing, Orana Engineering was asked to provide electrical engineering and mechanical engineering assistance with provision of a concept design for the proposed refurbishment and upgrade.

By working closely with Glencore, and other consultants engaged on the project, Orana Engineering was able to contribute as part of a collective "owners engineering team" to the feasibility assessment of a significant engineering project in the Townsville Region.

Underground Workshop Concept Design

Due to expanding operations, Glencore's Oaky North underground operations saw benefit in having an underground workshop and refueling stations to reduce vehicle travel times and increase efficiencies. Orana Engineering was engaged to provide concept design and estimating assistance for project approval.

From communications with our client, Orana Engineering prepared concept general arrangement drawings for consideration. Based on these concept design drawings, a project capital estimate and project schedule were prepared for Oaky North.

From the information presented by Orana Engineering, the client could accurately consider whether the underground workshop was feasible and ensure that appropriate budgeting and project planning was completed at the concept design phase to improve confidence in the project prior to execution.

Yokogawa DCS Upgrade

Since 2005, Orana Engineering has provided 24/7 support for Glencore's Oaky Creek Coal control systems. At the CHPP a Yokogawa DCS installed in 1998 is used as the primary control system. With existing CentumCS Unix software no longer supported by Yokogawa, it was essential to complete an upgrade to the CentumCS3000 system.

Orana Engineering developed conversion tools to allow configuration data to be extracted from the CentumCS Unix platform and imported into the CentumCS3000 environment. These tools provided efficiency and accuracy for the conversion and delivered a significant cost saving.

The quality of conversion tools and simulation programs developed by Orana Engineering resulted in highly efficient site commissioning, completed without plant downtime.