Client Engineer

The role of a Client Engineer is to be the client’s eyes and ears on a project, representing the client and working within their site systems and procedures. A Client Engineer can remove the hassle and free up the time of those on site to deal with day to day operations. It is a way to supplement the knowledge and experience held by those onsite, adding a resource to focus on the technical detail, and contributing to areas of specific expertise, for example Electrical Engineering. A Client Engineer is also sometimes referred to as an Owner's Engineer or Principal's Representative.

Working in the capacity of an advisor to the client, a Client Engineer can help to provide an additional resource for a project or specialist for a one-off task. They can also play a key role in developing contracting or purchasing strategies for projects, as well as acting as a mediator between clients and contractors should disputes arise.

Engaging a Client Engineer adds value to a project through time savings, with a greater potential to capture issues in the design phases and prevent issues before they are realised. Other benefits for the client include:

- Having a dedicated expert involved at every step of the process gives the ability to objectively identify and troubleshoot potential issues before they arise, resulting in potentially significant cost savings and preventing unnecessary schedule delays;

- Time savings are made by freeing up site management to deal with the bigger picture of the project, or the day to day operations. Our Client Engineers are able to relieve the hassle and pressure by dealing with the technical queries that may come from suppliers and contractors, and spending the time to focus on the task at hand;

- Ensuring that a client’s needs are accurately interpreted and the outcome the client receives is what they wanted and meets their HSEC and quality expectations;

- Allowing access to additional, skilled staff as a temporary resource to supplement technical areas as required, without the ongoing overhead of permanent staff; and

- Keeping the client well informed - the Client Engineer will monitor the technical aspects of the projects, filtering back the information that managers need to know.

At Orana Engineering, the Client Engineer can be a stand-alone service or offered in conjunction with our project management services. We have proven experience in this role, and have been the Client Engineer for projects up to $250M.

The unique skill set of the personnel at Orana Engineering combines the necessary technical knowledge and expertise with practical site backgrounds to ensure the services offered deliver real value to our clients. This first-hand knowledge and understanding of how to work within the systems and constraints of the site really make a difference in a role such as Client Engineer.

Contact Orana Engineering for further information about our Client Engineer services or to request a no obligation proposal. Or for more information about the services Orana Engineering can provide, please review our Capability Statement.

Orana Engineering Client Engineer

Village Kitchen Upgrade

The Village Kitchen at Glencore’s Hail Creek Mine camp was scheduled for upgrade with Orana Engineering engaged to provide engineering support for electrical, civil and building works, including a new shed. A site visit was conducted to determine the scope of the upgrade and to collect site information comprising photos, drawings, measurements and location of water and gas services.

From the information gathered, Orana Engineering provided engineering design and project management of the Village Kitchen upgrade including a new shed distribution board, concrete slab, layout and connection of services to the new shed and prepared a detailed scope of work document for tendering purposes.

Orana Engineering design drafters produced RPEQ certified GA and concrete drawings showing details of services to be relocated, a slab and loading dock drawing, a new single line diagram for the distribution board, and revisions to existing distribution board drawings.

Light Poles Review

Orana Engineering was contacted by Glencore’s Oaky Creek Coal Mine to undertake a structural review of lighting towers situated at the Tieri township sporting oval. Existing tower bases had been buried for approximately 20 years and were displaying evidence of corrosion to anchor bolts and baseplates.

Orana Engineering conducted a review of client-supplied documentation and photographs and gathered additional information to determine repair requirements. Following the review, a letter of recommendation was provided to the client outlining repairs required for continued operation of the lighting towers, with RPEQ structural supervision.

Additional support was provided by Orana Engineering with a further review of lighting towers within the Tieri Aquatic Centre and Shopping Centre. In this instance Orana Engineering was also able to capture 3D data from light poles using its Faro 3D laser scanner. The client was presented with recommendations for tests or further analysis required.

Sampler PRT Documents

Process engineering personnel at Glencore’s Oaky Creek coal mine identified a need for review and gap analysis of existing coal sampler PRT (Production Resources / Tools) SAP documents, to determine where these differed from the recommendations of the original equipment manufacturers (OEMs) and from the PRTs of other Glencore sites.

The assistance of Orana Engineering was sought in conducting the review and documenting differences or gaps identified, for further discussion with site engineering contacts. Outcomes from the analysis were documented in the form of a Gap Analysis Register for client review.

With client approval, revised or additional PRT’s were developed by Orana Engineering as required to close all gaps, with changes then presented to the client to determine any final modifications to be made prior to handover.

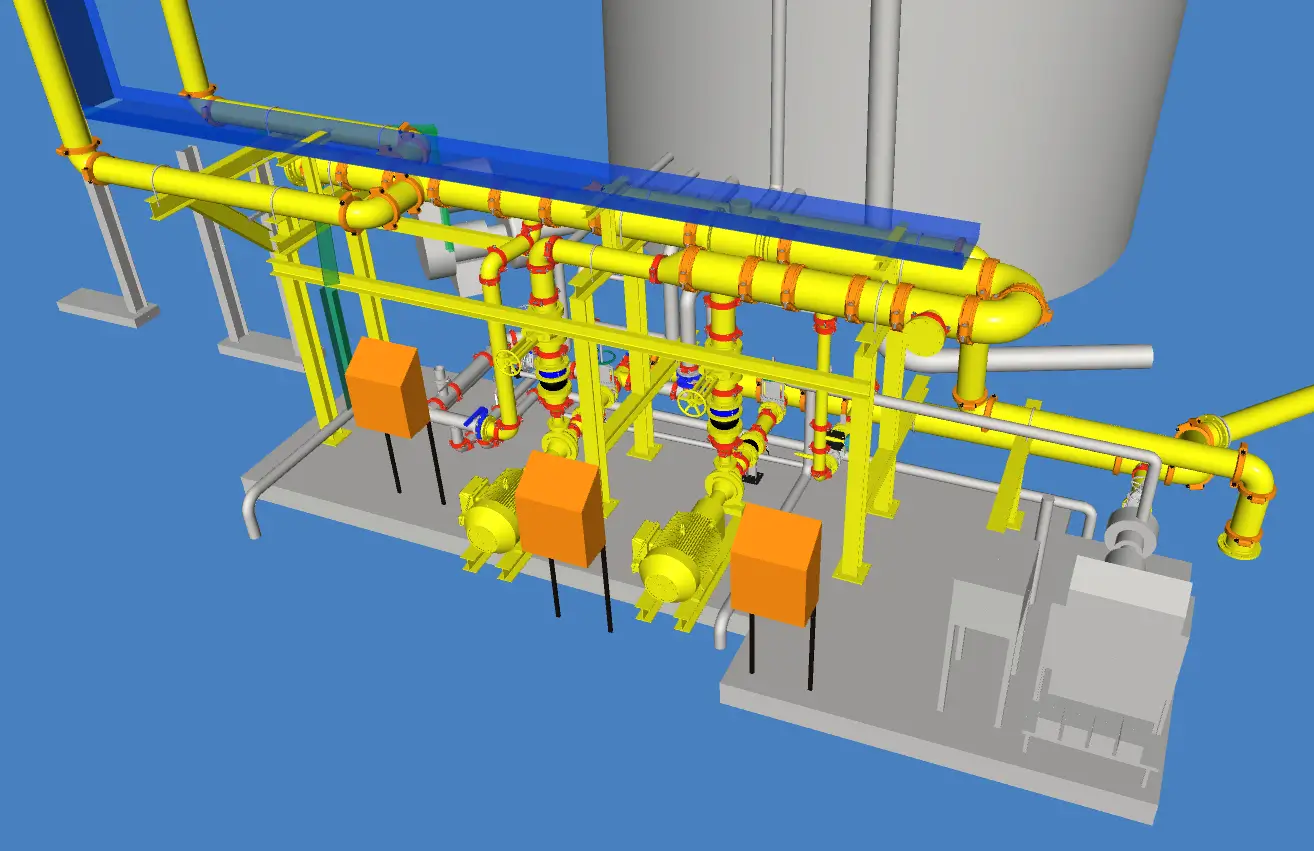

Clarified Water Upgrade

Orana Engineering was consulted by Glencore’s Collinsville mine to assist with an upgrade of its CHPP washdown water distribution system. The CHPP clarified / raw water is supplied from either an anti-pollution pond or the raw water Sunwater pipeline, with the wash water distribution network delivering water to the yard area, CHPP washdown sprays, lime / flocculant dosing or conveyors for spray bars and washdown.

Following hydraulic modelling, Orana Engineering’s mechanical engineers delivered a design with improved flow and pressure, (increasing capacity from 375 to 700 cubic meters per hour) while structural engineers produced SpaceGASS modelling of pipe supports and 3D modelling of the discharge structural steel pipe rack. Additionally, a Functional Specification or Function Description was produced for integration of the design into the plant's control system.

Project deliverables included an Equipment Register, Scope of Supply, detailed Construction and Installation Scope of Work for Tender, Functional Description and detailed design drawings.

.jpg)

Oily Water Pond

Origin Energy’s Talinga Gas Plant oily water system treats water created during the gas compression process. Effluent from the system is pumped into the water-gathering network, delivering water to the main water treatment plant.

Orana Engineering was engaged by Origin Energy to evaluate the oily water system and conducted a high level assessment of options to reduce the risk of uncontrolled release of contaminated water from the wetlands system that was controlled by interim means.

Outcomes were presented to the client summarising options to reduce or eliminate identified risks. Orana Engineering subsequently provided detailed mechanical and electrical design and drafting for the approved option.

Deliverables for the project included a basis of design document, detailed design and a revison of the Wetland Operations & Maintenance Manual.

Gas Turbine No.1 Protection Relay Upgrade

Incitec Pivot was looking to replace an existing turbine generator pole slip relay unit at its Phosphate Hill Power Station. Existing pole slip relays had become obsolete and were at the end of their expected life. Pole slip relays perform a critical protection function for turbine generators and operation of a generator without its pole slip relay would pose an unacceptable risk. Consequences of relay failure on turbine generators would be multiple gas turbines being unserviceable and resulting in power shortages across the site.

The project scope involved replacement of Multilin 489 protection relay with new Multilin 889 for a 4.5MW gas turbine generator as well as integration of pole slip protection and a synchronisation check facility into the Multilin 889.

Orana Engineering’s input for the project included electrical engineering design, protection configuration, on site project management and commissioning.

Airport Lighting

Incitec Pivot’s Phosphate Hill site contacted Orana Engineering to request assistance with evaluation of its Monument Aerodrome runway and apron lighting system following a review of potential electrical hazards.

An assessment of the airport lighting installation was undertaken by Orana Engineering electrical engineering personnel with findings presented to the client in report format. Review considerations included reference to CASA and Australian Standards and outlined a high level risk assessment conducted to quantify electrical safety risks.

Following client consideration of recommendations, Orana Engineering provided front end loading (FEL 3) documentation for replacement of existing runway and taxiway lights, series isolation transformers and the existing lighting control system. A scope of work was then prepared with the tender process managed by Orana Engineering on behalf of the client for the appointment of a specialist airport lighting contractor to complete design and construction of the lighting and control system upgrades.

_1.webp)

Fire Pumps Automation

The main plant raw water boost pumps at Glencore’s Oaky Creek Coal were supplied via a starter panel which required replacement due to water inundation and for improved functionality, reliability and compliance.

At the client’s request, Orana Engineering provided a report outlining preliminary design checks completed and provided a high-level summary of installation works required to the pump starter panel for a new MCC already on site.

Multiple upgrades were required to electrical equipment as well as associated civil / structural works. A preliminary concept sketch was prepared giving an overview of proposed upgrades. An Orana Engineering Electrical Engineer was appointed to assist with onsite commissioning of the raw water boost pumps and to provide offsite assistance with DCS configuration.

Deliverables to the client included electrical engineering and design drawings to IFA/IFC, a scope of work and a bill of materials.

Conveyor Commissioning Sheets

Anglo American Grosvenor Mine sought the assistance of Orana Engineering in developing check sheets for reference by site personnel during underground conveyor commissioning processes.

Firstly, Orana Engineering produced an extensive Inspection & Test Register covering the civil and mechanical components of the various conveyor systems on site. The Register provided a breakdown of all system areas required to be covered by the commissioning check sheets.

Close communication between site and mechanical personnel from Orana Engineering ensured a comprehensive list of inspection and testing tasks was produced, covering all of the checks to be undertaken during conveyor commissioning.

From the approved Inspection & Test Register, approximately 190 individual check sheet templates were issued for review and approval by site management prior to use by mine personnel during the commissioning process.

Cable Failure Investigation

MMG’s Dugald River Mine in north-west Queensland had experienced issues with LV cables feeding large MCCs on site. Following damage to a cable, gland and gland plate within the Flotation Area MCC, Orana Engineering was engaged to conduct an investigation into the cause.

The faulted cable and two un-faulted cables from the same MCC incomer were transported to Orana Engineering’s Townsville office where they were inspected, dismantled, measured and photographed. A review of site data was carried out with conclusions indicating the most likely cause of failure was degradation of cable insulation due to heat generated at the cable gland by a circulating current in the armour of the single core cable.

Orana Engineering’s findings and methods for preventing similar occurrences were presented to the client in report format at the conclusion of the investigation.

Ash Water Treatment Plant

CSE Energy’s Kogan Creek Power Station identified that due to higher than normal rainfall its decant pond had neared capacity and was unlikely to evaporate in an acceptable timeframe by either natural means or with the assistance of fans. It was proposed to reuse the water on site, however due to a concentration of suspended silt the decant water required treatment before being returned to the plant. The solution was sourcing and installation of a containerised water clarification plant.

Orana Engineering was contacted for provision of electrical engineering design and support for power and control of the proposed ash water treatment facility as well as mechanical engineering input with pumping, piping and tank design for water supply and tie-in to existing infrastructure.

CHPP Projects - Water Balance

Orana Engineering was requested by the CHPP Manager Capital Projects at Glencore’s Collinsville coal mine to provide engineering and scoping assistance with respect to the mine’s underground water service repair and upgrade scope of work.

A member of the Orana Engineering mechanical engineering team attended site to liaise with onsite stakeholders, operators, plumbers and surveyors and to gather information on raw water and potable / fire water supply issues being experienced.

Upon return from site, a high-level engineering review was conducted along with detailing of raw water and potable / fire water scopes. Basic hydraulic modelling was also carried out to identify pressure spike issues and water hammer. Following review completion, the client was provided with a basis of design and a summary of Orana Engineering’s findings and recommendations.

CHPP Structural Repairs - CBN302

Glencore's Collinsville Coal Mine engaged Orana Engineering to develop a deconstruction safe work methodology for demolition and deconstruction of the CBN302 reject bin, along with appropriate risk assessment documentation based on the deconstruction methodology.

Key considerations were ensuring that the bin and structure supporting the conveyor head end were maintained in a safe and stable condition during deconstruction and that the risks of stored energy in the curved bin shell plates was managed through the steel thermal cutting process (avoiding steel plate spring-back hazards).

Orana Engineering’s basis of design determined the necessary steps to safely remove the redundant CBN302 reject bin.

Detailed design and engineering provided by Orana Engineering included 3D modelling of the reject bin and structural steelwork to assist in preparing the methodology images.

CHPP Structural Repairs - Clevis Plates

The CHPP Structural Supervisor at Glencore’s Collinsville Coal Mine requested the services of Orana Engineering in completion of a structural review and provision of a replacement methodology for the CCV101 Trestle Clevis Plates.

Orana Engineering’s consultation included a structural review of documents and existing drawings, identification of load-bearing elements and weak points, analysis of existing design and indication of necessary modifications. Additionally, the review included development of a strengthening plan and methodology utilising temporary bracing and support systems to lift the structure for trestle clevis plate replacement and avoid working under suspended loads using props.

Outcomes from the project included a letter of recommendation with instructions for the trestle clevis plates replacement works, including notes and methodology, mark-ups of site photos and drawings to illustrate the proposed replacement methodology.

CHPP Maintenance Work Instructions

The CHPP Maintenance Superintendent at Glencore’s Collinsville Coal Mine sought the assistance of Orana Engineering in developing Work Instructions for various maintenance processes carried out within the CHPP.

Two Orana Engineering Mechanical Engineers were assigned to attended site on multiple occasions during scheduled plant shutdowns to review processes and either update existing or generate new Maintenance Work Instructions for multiple functions and locations within the CHPP.

Finalised Work Instructions were subsequently presented to the client for final approval prior to incorporation / upload into Collinsville’s resource library.

LOM Raw Water Supply Plan

Raw water pressure problems within the longwall and development mining areas at Xstrata Coal's Oaky No.1 Underground Coal Mine had resulted in numerous production delays. At the client’s request, Orana Engineering undertook a Life of Mine (LOM) study to develop a raw water supply plan based on strategic booster pump positioning.

Hydraulic modelling was subsequently completed by Orana Engineering based on the Raw Water Supply Network LOM Study and taking into account the effects of firefighting demand pressures, flow rates and water hammer.

Results were summarised in a pump positioning flow sheet and a pump positioning plan to illustrate recommended current and future booster pump positions required to achieve minimum raw water supply pressures and flow rates.

Reagents Tank Farm Rectification

Due to the existing system not being compliant to site standards, BMA Saraji Mine had constructed a new reagents system for the supply of diesel and MIBC into their CHPP. Following construction, several attempts were made to wet commission the system however these were unsuccessful due to multiple problems identified by the client.

Orana Engineering was requested to undertake a complete design review of the reagents system, to outline problems with the design and to provide a scope of work to rectify these such that wet commissioning could be completed.

At the conclusion of the review a bill of materials for the commissioning scope of work was provided, detailing procurement specifications for required mechanical equipment and spares.

CHPP Samplers

Orana Engineering provided client engineer and project management support for the design and installation of a new product coal sampler at Glencore's Collinsville Mine CHPP. The scope also included civil engineering support and design drafting for the concrete footings which were out of scope for the sampler supplier.

Orana Engineering's project manager provided onsite support as required to deliver the multidisipline design and installation taking into account the requirements of site stakeholders in the brownfield site.

Tertiary Crusher Upgrade

Orana Engineering was called upon by Glencore's Collinsville Open Cut Coal Mine to provide engineering, drafting and project management for an upgrade to its tertiary crusher and supporting structure, involving multiple site visits to assist with on-site aspects of the construction phase.

The basis of design included engineering and drafting to understand and develop the FEED and scope for the capital project, designing of the support structure to install the replacement tertiary crusher and provision of package management for the entirety of the project.

Some of the primary deliverables for the project included 36x IFA / IFC drawings for the tertiary crusher structure upgrades, a critical spares list (including liaison with vendor), fabrication scope of work for tendering, a Change Management document, and a Risk Assessment.

PPP027 Plant Feed Upgrade

Century Mining’s zinc tailings treatment operation is situated in north-west Queensland and is the largest tailings retreatment operation in Australia. Century sought the services of Orana Engineering in providing engineering support for its PPP027 Plant Feed Upgrade Project.

The project scope encompassed multidisipline engineering design for the upgraded plant feed pumping system including Weir Warman pumps. The client also requested a mechanical engineering review into combined use of poly lined, rubber lined and UHMWPE piping supported by Orana Engineering’s liaison with product vendors. Electrical design and site based support was delivered by Orana Engineering to suit the requirement of the project resources and timeline. Civil and structural engineering design was completed for the underground services and concreted area and footings.

.webp)

QGC AIWT Design Review

Hutchinson Builders Toowoomba was contracted to deliver portions of the Water Aquifer Injection Trial at QGC’s Woleebee Creek site. Prior to construction, Hutchinson Builders engaged Orana Engineering to perform a design review of all mechanical technical documentation associated with the Pond Transfer Pump Station.

The review aimed to determine whether sufficient detailed information had been provided to allow Hutchinson Builders to successfully complete construction. Orana Engineering completed and issued a design review report which detailed recommendations from the review.

During construction, Hutchinson Builders also engaged Orana Engineering to perform an inspection of a buried HDPE pipeline and to assess the construction of the pipeline against requirements of engineering drawings and specifications.

Conveyor Upgrade Project

Carborough Downs Coal Underground Mine had transitioned from a bord and pillar mining system to longwall. The result was a need to upgrade capacity of the coal clearance conveyor system. Orana Engineering was engaged to provide Client Engineering assistance to deliver underground conveyor equipment to meet the longwall production schedule.

Orana Engineering monitored vendor design progress against the schedule, performed design reviews to ensure correction of errors prior to final client approval, monitored and managed fabrication and delivery schedules and managed budget and variations in line with the contract.

By co-ordinating with the client’s installation group and managing the vendor in line with the client’s schedule, the conveyors were successfully installed and made available for longwall production.

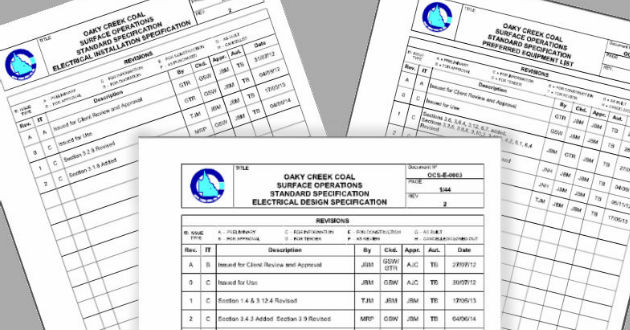

Electrical Specifications

For site consistency of electrical design and installation standards and compliance with Australian standards and legislation, Glencore Oaky Creek Coal engaged Orana Engineering to prepare new site electrical specifications. The scope combined existing site specifications and practices and, where applicable, incorporated them into the new specifications. These specifications included:

- Electrical Design

- Electrical Installation

- Preferred Electrical Equipment List

- Site Equipment Numbering

- Drawing Management

Orana Engineering’s extensive knowledge of Queensland mine sites and long-standing experience at Oaky Creek enabled specifications to be produced cost effectively and fully inclusive of site specific details. Orana Engineering continues to maintain these documents for Oaky Creek Coal, ensuring that latest versions are readily available to site personnel via Oaky Creek’s drawing management system.

MIBC & Diesel Upgrade

The purpose of the Reagent System Upgrade at Oaky Creek was installation of new reagent storage tanks, discharge / delivery pumping systems and automated flow control distribution manifolds for the delivery of each reagent to the nominated process connections.

Orana Engineering performed mechanical, electrical and control systems design, drafting and engineering for the project. The primary deliverables included scope of works, construction drawings, functional specification, BOM, spares lists and equipment / instrument data sheets.

Orana Engineering managed the onsite commissioning of the system and provided a system handover to operations for implementation. An Operation & Maintenance Manual and Hazardous Area Dossier were provided on project completion.

Onsite Accommodation Camp Services

Orana Engineering was engaged by Oaky Creek Coal to assist in design and construction of onsite camp accommodation, including an HV substation for power and potable water supply.

The brief included mechanical, electrical and control systems design, drafting and engineering for the project. Deliverables included scope of works, construction drawings, functional specification, drawing and equipment registers, commissioning and operating spares lists and equipment and instrument data sheets.

Orana Engineering provided PLC configuration and commissioning assistance for pump control, acted as Client Representative during construction, managed onsite commissioning of the system, and provided a handover to operations for implementation.

Operation & Maintenance Manuals for potable water storage and the HV substation were provided upon completion.

Sewage Treatment Plant Refurbishment

To increase productivity and maintain compliance with legislative standards, Glencore Oaky Creek Coal employed the services of Orana Engineering to design and manage the electrical aspects of an upgrade to their existing sewage treatment plant.

The project was managed on-site by others, with Orana Engineering providing electrical engineering, design, project management and construction / commissioning assistance.

Upon completion of installation, Orana Engineering updated all drawings to reflect any changes made, thus providing Glencore Coal with as-built drawings which will make any future maintenance or fault-finding work more efficient and cost effective, as well as providing legislative compliance.

Site DCS Support

The CHPP at Oaky Creek Coal utilises a Yokogawa Distributed Control System for control and monitoring of their operation. The system incorporates Yokogawa’s OPC server and Exaquantum data historian. OCC utilises multiple Programmable Logic Controllers for specific operational purposes, with a number of PLC's interfaced back to the DCS for control and monitoring functions.

Since 2005, Orana Engineering has provided 24/7 support for Oaky Creek’s control system. Day to day support is provided by remote access, which is cost effective and highly responsive. Additionally, onsite support for hardware solutions and commissioning of larger projects is provided as required.

Tippler Refurbishment Feasibility

Glencore Port Operations in Townsville operate an export facility for minerals concentrate and refined copper within the Port of Townsville precinct. The concentrate in-loading rotaside tippler was identified as being at end of life and a feasibility study was commissioned to review a like-for-like replacement option for refurbishment of the tippler.

To facilitate feasibility-level costing, Orana Engineering was asked to provide electrical engineering and mechanical engineering assistance with provision of a concept design for the proposed refurbishment and upgrade.

By working closely with Glencore, and other consultants engaged on the project, Orana Engineering was able to contribute as part of a collective "owners engineering team" to the feasibility assessment of a significant engineering project in the Townsville Region.