Engineering Maintenance & Support

Engineering maintenance and support is an essential service over the life of an operation and includes scheduled maintenance services as well as support for breakdowns and failures. We follow a logical fault finding process to identify the root cause and where applicable provide recommendations to reduce the likelihood and/or consequences of the event occurring again.

Through our engineering maintenance and support services, Orana Engineering strives to build long term relationships with our clients. Building long term relationships is an integral part of our business model and business philosophy and it gives us the best opportunity to be a resource that is valued by our clients. We believe that this value comes, over time, from better knowing our clients' sites, systems and people. From this knowledge we can provide engineering services that are tailored to our clients' requirements.

Our engineering support services include control systems support, training and commissioning as well as client engineer services. We provide engineering maintenance and support for coal, metalliferous, oil and gas clients as well as industrial and commercial clients.

Explore the case studies below for more information on maintenance and support services by Orana Engineering.

Orana Engineering Maintenance & Support

Ash Water Return Pipeline Replacement

Ash slurry at CS Energy’s Kogan Creek Power Station is pumped to various locations around site via a pipeline originally installed for delivery of service water from the power station to the crusher area. With proposed pumping equipment capable of higher pressure output, a project was set up to review the engineering calculations and potential risks.

Orana Engineering was engaged to conduct concept design investigations considering options for repair or replacement of the pipeline. Outcomes from the review were provided to CS Energy summarising options considered and proposing the use of carbon steel (potentially lined for corrosion resistance) as the optimal replacement for fibreglass piping. Advantages and disadvantages of carbon steel were also presented such that the client was fully apprised of its properties.

As only limited drawings of the existing pipeline were available, Orana Engineering design drafters produced pipeline general arrangements for information.

Light Poles Review

Orana Engineering was contacted by Glencore’s Oaky Creek Coal Mine to undertake a structural review of lighting towers situated at the Tieri township sporting oval. Existing tower bases had been buried for approximately 20 years and were displaying evidence of corrosion to anchor bolts and baseplates.

Orana Engineering conducted a review of client-supplied documentation and photographs and gathered additional information to determine repair requirements. Following the review, a letter of recommendation was provided to the client outlining repairs required for continued operation of the lighting towers, with RPEQ structural supervision.

Additional support was provided by Orana Engineering with a further review of lighting towers within the Tieri Aquatic Centre and Shopping Centre. In this instance Orana Engineering was also able to capture 3D data from light poles using its Faro 3D laser scanner. The client was presented with recommendations for tests or further analysis required.

Sampler PRT Documents

Process engineering personnel at Glencore’s Oaky Creek coal mine identified a need for review and gap analysis of existing coal sampler PRT (Production Resources / Tools) SAP documents, to determine where these differed from the recommendations of the original equipment manufacturers (OEMs) and from the PRTs of other Glencore sites.

The assistance of Orana Engineering was sought in conducting the review and documenting differences or gaps identified, for further discussion with site engineering contacts. Outcomes from the analysis were documented in the form of a Gap Analysis Register for client review.

With client approval, revised or additional PRT’s were developed by Orana Engineering as required to close all gaps, with changes then presented to the client to determine any final modifications to be made prior to handover.

Boiler Structural Brace

CS Energy’s Kogan Creek Power Station was experiencing intermittent lateral vibration in the structural bracing of two of its boilers. The assistance of Orana Engineering was sought in conducting a structural and vibrational engineering review of the affected plant to determine the source of the issue. The review included SpaceGASS modelling of the local structure surrounding the bracing to assess loading and determine member sizing. A modal vibration analysis was completed to determine the natural frequencies of the plant and structural bracing.

Following review, the option of installing cables for the bracing was discounted and it was recommended that new bracing for structural members be installed and connected to the midpoint on either side using a custom designed clamped fitting (to avoid welding to existing loaded brace) and installing a new cleat at the main structural member. The design solution increased the lowest natural frequency vibration mode shape for the structures and also reduced visible deflection.

Orana Engineering deliverables for the project included a Boiler Structural Beam Plan Arrangement and detail drawing ‘issued for construction’.

Airport Lighting

Incitec Pivot’s Phosphate Hill site contacted Orana Engineering to request assistance with evaluation of its Monument Aerodrome runway and apron lighting system following a review of potential electrical hazards.

An assessment of the airport lighting installation was undertaken by Orana Engineering electrical engineering personnel with findings presented to the client in report format. Review considerations included reference to CASA and Australian Standards and outlined a high level risk assessment conducted to quantify electrical safety risks.

Following client consideration of recommendations, Orana Engineering provided front end loading (FEL 3) documentation for replacement of existing runway and taxiway lights, series isolation transformers and the existing lighting control system. A scope of work was then prepared with the tender process managed by Orana Engineering on behalf of the client for the appointment of a specialist airport lighting contractor to complete design and construction of the lighting and control system upgrades.

_1.webp)

Terminal Dam MCC

The Terminal Dam pump station at Glencore’s Oaky Creek coal mine is critical in supplying the mine and township of Tieri with raw water. The existing pump station had been in service for over 30 years during which time the electrical reticulation equipment had regular maintenance but no significant upgrades. Obsolete components, changes in Standards and degradation of the equipment all signaled that the HV supply, LV MCC and LCU’s was apporaching its end of service.

At the request of Oaky Creek Coal, Orana Engineering undertook offsite electrical and control system engineering and design drafting for a Terminal Dam HV upgrade and MCC replacement. An update of the Electrical Installation SOW for the modification at Terminal Dam was prepared prior to attending site to complete the configuration and assist with project management of installation and commissioning works.

Precipitator Controllers

Incitec Pivot contacted Orana Engineering for assistance in identifying options for upgrading its Mount Isa Acid Plant Electrostatic Mist Precipitators (EMP). This was primarily to mitigate issues with EMP 7 and 8 which were contributing to low dust capture efficiencies, converter catalyst degradation and potentially premature damage to tube bundles.

Orana Engineering electrical engineering personnel sourced additional information on issues experienced and liaised with equipment manufacturers for recommended solutions. A design review table was prepared to summarise and document data from previous reviews including reports, tests, inspections and previous recommendations.

Orana Engineering provided offsite assistance in co-ordinating procurement and installation with deliverables to the client comprising the finalised design review summary table, BOM, equipment quotes and redline drawing mark-ups for upgrade of the EMP controller.

Main Sub Upgrades

The main substation at Glencore’s Oaky Creek Coal is essential for surface operations. Site personnel had highlighted multiple projects for implementation to collectively improve the integrity and reliability of the main sub. For each of the projects there were common elements and beneficial outcomes for executing them concurrently.

Given the critical nature of the projects and the importance of success, Orana Engineering developed a project management and design scope for provision of a dedicated Electrical / Control Systems Engineer from its Engineering Team.

Projects under the scope consisted of safety and reliability upgrades for OCC Main 66 / 11kV substation including automated racking of circuit breakers, interlocking of transformer tap changers and parallelling control, cable pit sump pump control.

Work undertaken included detailed design, PLC and DCS configuration, protection relay configuration, racking controllers, and commissioning whilst also mananging the client's drawing management system.

Brine Concentrator Stair Tower Rescue Lift Points

Veolia Water’s Kenya Water Treatment Plant contacted Orana Engineering to provide engineering and design drafting assistance in relation to installation of fall-arrest rescue anchor points to the brine concentrator stair tower.

Orana Engineering mechanical personnel undertook a review of applicable codes and standards in order to identify key safety considerations in the use of fall arrest systems. Calculations were performed on existing structural members locally to determine beam capacity for the addition of lugs at 6 points as identified by the client.

Deliverables for the project included an RPEQ supervised design for manufacture and installation of the lugs, revision of existing client drawings to reflect design changes and creation of a new drawing including both general and detailed information for new lug locations.

Conveyor Commissioning Sheets

Anglo American Grosvenor Mine sought the assistance of Orana Engineering in developing check sheets for reference by site personnel during underground conveyor commissioning processes.

Firstly, Orana Engineering produced an extensive Inspection & Test Register covering the civil and mechanical components of the various conveyor systems on site. The Register provided a breakdown of all system areas required to be covered by the commissioning check sheets.

Close communication between site and mechanical personnel from Orana Engineering ensured a comprehensive list of inspection and testing tasks was produced, covering all of the checks to be undertaken during conveyor commissioning.

From the approved Inspection & Test Register, approximately 190 individual check sheet templates were issued for review and approval by site management prior to use by mine personnel during the commissioning process.

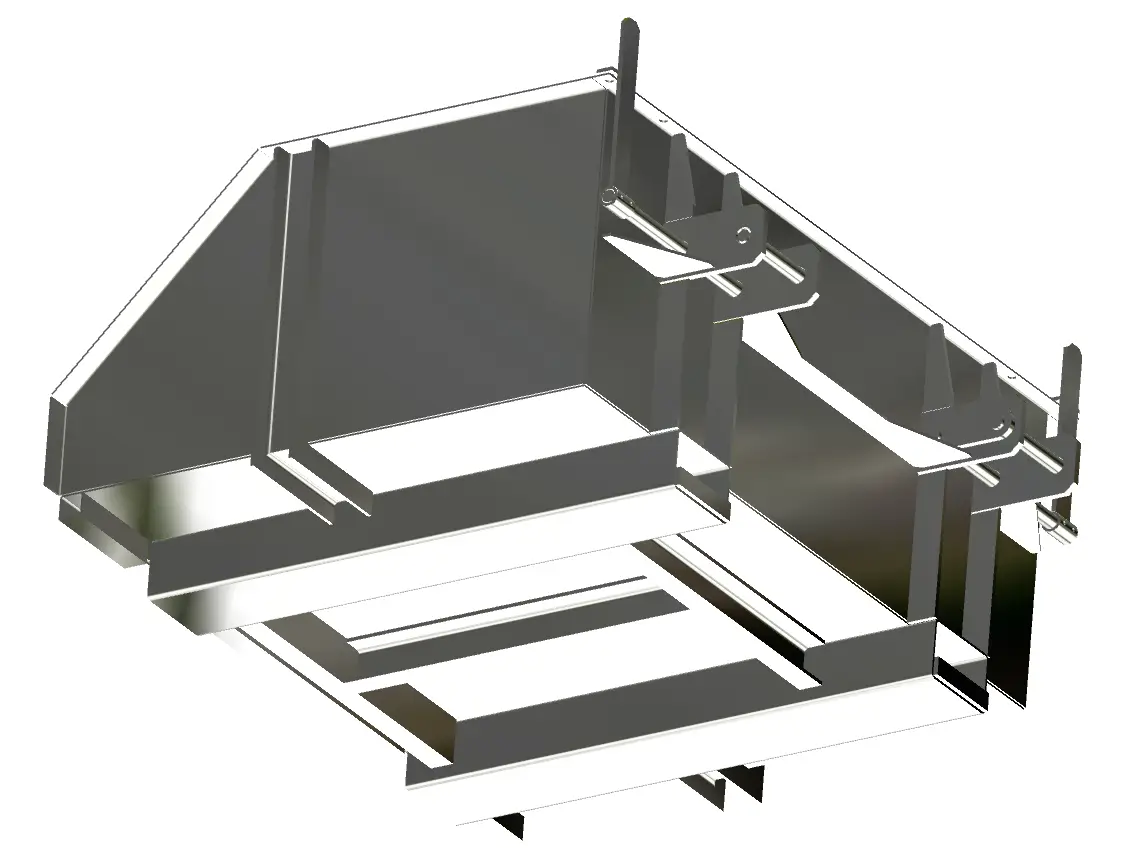

Telehandler Bin Design

At the request of Carborough Downs Coal, Orana Engineering initiated the design of a new bin for collection of used coal samples within the CHPP. Up until that point practice had been to transport samples to the bin by wheelbarrow, with the barrow then lifted (rather than levered) and the contents tipped into the bin.

Carborough Downs requested that Orana Engineering design a bin to enable wheeling of the barrow into the bin such that the contents could be tipped without the need to lift the barrow. Once full the bin would be collected via a telehandler and emptied onto the rejects pile.

Orana Engineering designers prepared a high level 3D model of the proposed telehandler bin, a 3D design of the lifting and pivot mechanism and bin fabrication, detail and assembly drawings with RPEQ Supervision.

.jpg)

GCB Enclosure

Origin Energy sought assistance from Orana Engineering in providing a concept design for shade shelters to be retro-fitted to existing GCB enclosures at its Uranquinty Power Station in southern New South Wales. The objective of the shelters was to reduce rainwater contact with GCBs and the design to be such that shelters could be lifted off for periodic maintenance of GCBs.

A third party undertook 3D scanning of the existing cover structures and provided resultant scan data for 3D modelling by our design team. SpaceGASS modelling of the structures and analysis of compliance to Australian Standards was also conducted prior to provision of the new enclosure concept to Origin Energy for review. Upon receipt of design approval, Orana Engineering developed and issued a scope of work for supply and installation of the GCB enclosure shelters.

Cable Failure Investigation

MMG’s Dugald River Mine in north-west Queensland had experienced issues with LV cables feeding large MCCs on site. Following damage to a cable, gland and gland plate within the Flotation Area MCC, Orana Engineering was engaged to conduct an investigation into the cause.

The faulted cable and two un-faulted cables from the same MCC incomer were transported to Orana Engineering’s Townsville office where they were inspected, dismantled, measured and photographed. A review of site data was carried out with conclusions indicating the most likely cause of failure was degradation of cable insulation due to heat generated at the cable gland by a circulating current in the armour of the single core cable.

Orana Engineering’s findings and methods for preventing similar occurrences were presented to the client in report format at the conclusion of the investigation.

CHPP Projects - Water Balance

Orana Engineering was requested by the CHPP Manager Capital Projects at Glencore’s Collinsville coal mine to provide engineering and scoping assistance with respect to the mine’s underground water service repair and upgrade scope of work.

A member of the Orana Engineering mechanical engineering team attended site to liaise with onsite stakeholders, operators, plumbers and surveyors and to gather information on raw water and potable / fire water supply issues being experienced.

Upon return from site, a high-level engineering review was conducted along with detailing of raw water and potable / fire water scopes. Basic hydraulic modelling was also carried out to identify pressure spike issues and water hammer. Following review completion, the client was provided with a basis of design and a summary of Orana Engineering’s findings and recommendations.

CHPP Structural Repairs - CBN302

Glencore's Collinsville Coal Mine engaged Orana Engineering to develop a deconstruction safe work methodology for demolition and deconstruction of the CBN302 reject bin, along with appropriate risk assessment documentation based on the deconstruction methodology.

Key considerations were ensuring that the bin and structure supporting the conveyor head end were maintained in a safe and stable condition during deconstruction and that the risks of stored energy in the curved bin shell plates was managed through the steel thermal cutting process (avoiding steel plate spring-back hazards).

Orana Engineering’s basis of design determined the necessary steps to safely remove the redundant CBN302 reject bin.

Detailed design and engineering provided by Orana Engineering included 3D modelling of the reject bin and structural steelwork to assist in preparing the methodology images.

CHPP Structural Repairs - Clevis Plates

The CHPP Structural Supervisor at Glencore’s Collinsville Coal Mine requested the services of Orana Engineering in completion of a structural review and provision of a replacement methodology for the CCV101 Trestle Clevis Plates.

Orana Engineering’s consultation included a structural review of documents and existing drawings, identification of load-bearing elements and weak points, analysis of existing design and indication of necessary modifications. Additionally, the review included development of a strengthening plan and methodology utilising temporary bracing and support systems to lift the structure for trestle clevis plate replacement and avoid working under suspended loads using props.

Outcomes from the project included a letter of recommendation with instructions for the trestle clevis plates replacement works, including notes and methodology, mark-ups of site photos and drawings to illustrate the proposed replacement methodology.

CHPP Maintenance Work Instructions

The CHPP Maintenance Superintendent at Glencore’s Collinsville Coal Mine sought the assistance of Orana Engineering in developing Work Instructions for various maintenance processes carried out within the CHPP.

Two Orana Engineering Mechanical Engineers were assigned to attended site on multiple occasions during scheduled plant shutdowns to review processes and either update existing or generate new Maintenance Work Instructions for multiple functions and locations within the CHPP.

Finalised Work Instructions were subsequently presented to the client for final approval prior to incorporation / upload into Collinsville’s resource library.

Crusher Gearbox

At the request of Glencore’s Collinsville Open Cut Coal Mine, Orana Engineering personnel attended site to perform a visual inspection on the CCR106 Abon Crusher following failure of the gearbox-to-crusher mounting studs.

The focus of the inspection was assessment of damage to impacted structural steel members on the crusher floor which had resulted from gearbox movement during the failure, and to troubleshoot the reason for the stud failure.

A summary of observations and supporting photos gathered during the inspection was compiled for presentation to the client. In addition, Orana Engineering provided a professional opinion regarding possible scenarios leading to failure of the mounting studs and offered recommendations for additional checks on the integrity of the crusher infrastructure.

Yard Machine Upgrades - 3D Scanning

Glencore's Collinsville Open Cut Coal Mine requested the assistance of Orana Engineering in conducting 3D laser scanning of its stockyard mobile equipment comprising raw, clean and bypass coal stackers as well as a raw coal reclaimer.

Scanning was carried out during a four day shutdown, utilising Orana Engineering's Faro 3D Laser Scanner. Upon return from site, post-processing of files was completed and scan data prepared for issue to the client.

At the conclusion of the assignment, scan data was provided in a format suitable for interrogation by others in 'issued for use' format.

Conveyor Upgrade Project

Carborough Downs Coal Underground Mine had transitioned from a bord and pillar mining system to longwall. The result was a need to upgrade capacity of the coal clearance conveyor system. Orana Engineering was engaged to provide Client Engineering assistance to deliver underground conveyor equipment to meet the longwall production schedule.

Orana Engineering monitored vendor design progress against the schedule, performed design reviews to ensure correction of errors prior to final client approval, monitored and managed fabrication and delivery schedules and managed budget and variations in line with the contract.

By co-ordinating with the client’s installation group and managing the vendor in line with the client’s schedule, the conveyors were successfully installed and made available for longwall production.

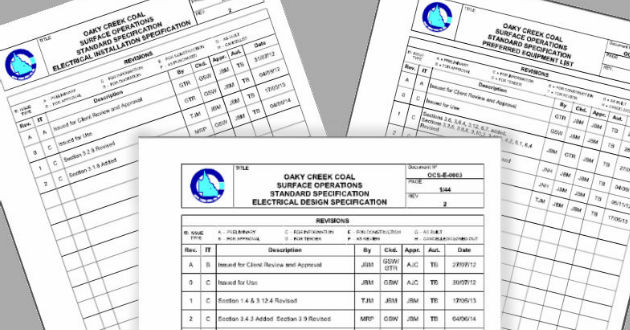

Electrical Specifications

For site consistency of electrical design and installation standards and compliance with Australian standards and legislation, Glencore Oaky Creek Coal engaged Orana Engineering to prepare new site electrical specifications. The scope combined existing site specifications and practices and, where applicable, incorporated them into the new specifications. These specifications included:

- Electrical Design

- Electrical Installation

- Preferred Electrical Equipment List

- Site Equipment Numbering

- Drawing Management

Orana Engineering’s extensive knowledge of Queensland mine sites and long-standing experience at Oaky Creek enabled specifications to be produced cost effectively and fully inclusive of site specific details. Orana Engineering continues to maintain these documents for Oaky Creek Coal, ensuring that latest versions are readily available to site personnel via Oaky Creek’s drawing management system.

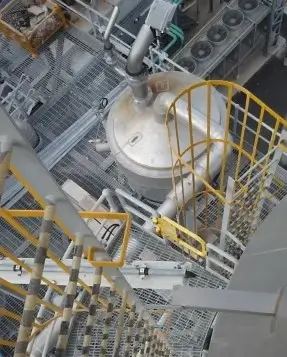

FB-028 Tank Lifting Beam

During an upgrade to the concentrator at MMG’s Century Mine, Orana Engineering was engaged to design a lifting beam for installation of a new flotation cell. The lifting beam design was to provide adaptation between lifting points on the tank and the crane, providing stability during lifting and protecting the integrity of the tank.

Structural considerations involved hand calculations and modelling in SPACE GASS based on client requirements and relevant Australian Standards. Orana Engineering's design utilised available structural members on site, providing cost benefits to the client.

Orana Engineering design staff created a 3D model in Autodesk Inventor, producing a fabrication drawing for the beam which also detailed the sling configuration for use during the lifting process.

Fire System Audit

BMA Gregory Crinum engaged Orana Engineering to perform an audit and inspection of the Crinum underground mine surface fire water system with respect to providing adequate pressure and flow for the Crinum North conveyor system and stockpile conveyor.

Orana Engineering completed a site inspection and audit against the design drawings, with site-verified information then used for compliance assessment in line with Australian Standards. The audit included in-depth assessment of the fire water system to Australian, BMA and site Fire Management Standards. Hydraulic modelling of the fire system was also undertaken to validate existing pressure measurements.

Orana Engineering was able to make recommendations regarding compliance and system hydraulic performance, which assisted BMA in improving system capacity.

Jaw Crusher Platform

The maintenance department of Eloise Copper Mine contacted Orana Engineering with a requirement for design of an access platform for their jaw crusher, including engineering certification and drafting. The client provided site measurements and a basic concept of the design they were looking for.

Being a brownfield engineering project, the design had to consider the surrounding area and existing structures to minimise modifications. Autodesk Inventor was used to create a basic 3D model of the area. Once the physical data was established the detailed design of the platform was able to be performed efficiently.

Orana Engineering was able to produce both detailed shop drawings for fabrication and site installation drawings, all of which were provided with structural engineering certification.

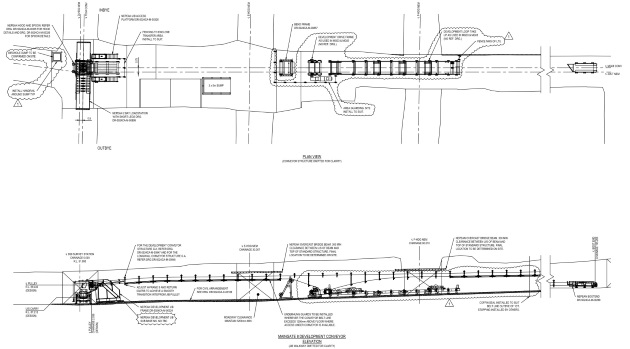

MG08 Development Conveyor

Carborough Downs Coal Mine is an underground operation utilising conveyors to transport mined coal to the surface for processing. As operations progress and new longwall headings are mined, new conveyor installations are also required.

Orana Engineering was engaged to design a new longwall drive-head chamber and conveyor installation, initially providing a drawing set detailing required drive-head chamber dimensions to suit the conveyor installation.

Using AutoCAD, a civil design and conveyor equipment arrangement was produced. The conveyor design had to consider several constraints, including available equipment, transfer tie-in to existing trunk conveyor, maintenance access, drainage, minimum clearances and belt curves.

Upon layout approval, AutoCAD drawings were produced detailing civil and mechanical design aspects, enabling site engineers to complete installation with efficiency while ensuring regulatory compliance.

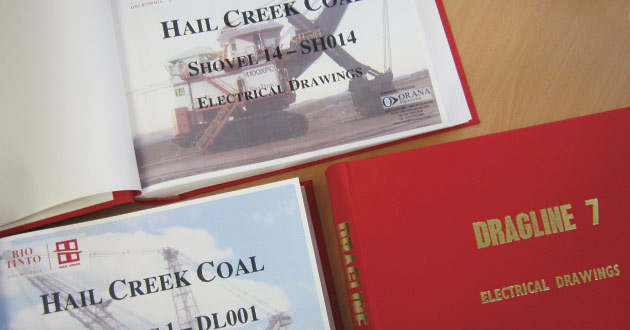

Mobile Plant Electrical Drawing Books

For personnel safety and compliance with Queensland’s Coal Mining Safety & Health Regulation it is a requirement for mine sites to provide electrical workers with access to up-to-date drawings for electrical equipment and electrical installations.

To improve the maintainability of plant electrical systems and personnel safety, Hail Creek Mine engaged Orana Engineering to create bound books of electrical drawings for Draglines 1 and 7 and Shovel 14. Multiple books were made for each machine in both A4 and A3 sizes and using waxed (waterproof) paper to ensure longevity.

Using vendor drawings from the client, Orana Engineering produced bound books containing all electrical power, control and termination diagrams associated with the respective mobile plant.

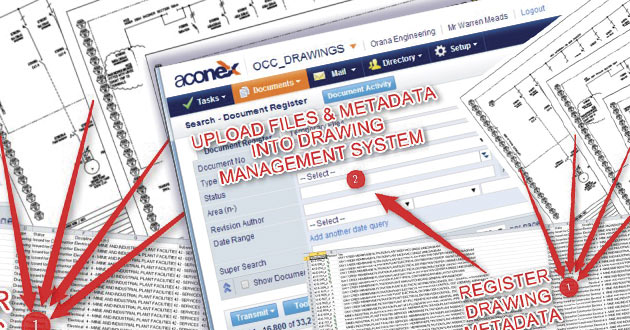

Process Water RO Plant Vendor Drawing Registration

Following commissioning of their Process Water Reverse Osmosis (RO) Plant, Oaky Creek Coal received approximately 150 electrical drawings from the vendor. To provide site personnel with access to the drawings, Oaky Creek engaged Orana Engineering to register these within their existing drawing management system.

There are many drawing management systems and tools on the market and Orana Engineering has the capabilities and resources to utilise whatever system is preferred by a client. Oaky Creek Coal sets a very high standard in the industry for the maintenance of drawings and in real terms realises the significant cost benefits that good drawing management delivers in enabling site personnel to perform effectively and safely.

Reagents Lightning Protection

To ensure the CHPP reagent tank farm lighting protection systems complied with Australian Standards, Moranbah North Coal requested Orana Engineering to undertake a review and design an upgrade of the lightning protection systems for the tank farm area.

With the area encompassing fuel storage tanks, it was classified as having structures with "explosive or highly flammable contents" and was therefore required to comply with AS1768:2008 Lightning Protection. Orana Engineering’s audit of the installation and its lightning protection systems confirmed that an upgrade of the facility was needed to comply with current lightning protection standards.

Utilising its team of detailed drafters Orana Engineering created a set of drawings detailing the work required to comply with AS1768:2008 Lightning Protection.

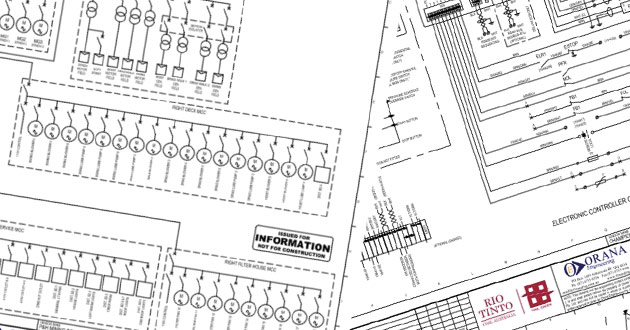

Redraw Dragline DL007 Drawings

To improve the maintainability of plant electrical systems and personnel safety, Hail Creek Mine employed the drawing revision services of Orana Engineering to redraw electrical power, control and termination diagrams associated with its Dragline 7 into AutoCAD format.

Having electrical drawings in CAD (computer aided design) format, is one of the most efficient ways to capture site electrical modifications, installations or as-building changes for ready access by site personnel involved in maintenance and operations.

Working closely with site contacts and onsite electricians, Orana Engineering was able to accurately reproduce 247 electrical drawings into AutoCAD for Dragline 7.

Redraw Electrical Drawings

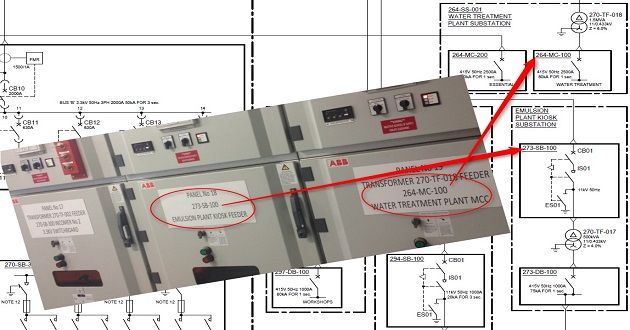

To ensure plant maintainability and personnel safety, Dyno Nobel employed Orana Engineering to redraw its low voltage and high voltage single line diagrams, while also confirming their accuracy and functionality.

Through the use of client photos, documentation and discussions Orana Engineering was able to accurately redraw 52 low voltage single line diagrams as well as 6 high voltage single line diagrams.

During the redraw process Orana Engineering identified that a larger size drawing template was required to ensure critical information was easily readable on a single drawing. An A0 size drawing template was designed to meet Dyno Nobel's drawing standards with the template providing links for the document management system to easily access drawing metadata.

Sewage Treatment Plant Refurbishment

To increase productivity and maintain compliance with legislative standards, Glencore Oaky Creek Coal employed the services of Orana Engineering to design and manage the electrical aspects of an upgrade to their existing sewage treatment plant.

The project was managed on-site by others, with Orana Engineering providing electrical engineering, design, project management and construction / commissioning assistance.

Upon completion of installation, Orana Engineering updated all drawings to reflect any changes made, thus providing Glencore Coal with as-built drawings which will make any future maintenance or fault-finding work more efficient and cost effective, as well as providing legislative compliance.

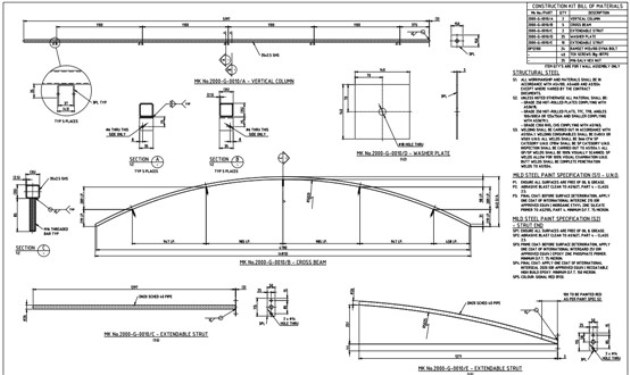

Tank Static Line

Management at Carpentaria Gold’s Ravenswood Operation enlisted Orana Engineering to design a fall arrest system that could be easily removed and repositioned above multiple leach tanks, allowing for safe removal and servicing of tank agitators.

From a site visit, Orana Engineering identified the need for an arrangement that could be easily disassembled and relocated to each leach tank. The design was challenging due to the varying nature of access structure members above tanks.

Orana Engineering designers proposed an assembly utilising a common set of supporting columns with struts of varying lengths depending on the work location. A full set of shop fabrication and assembly drawings were issued with the final design providing safety for personnel working above open tanks.

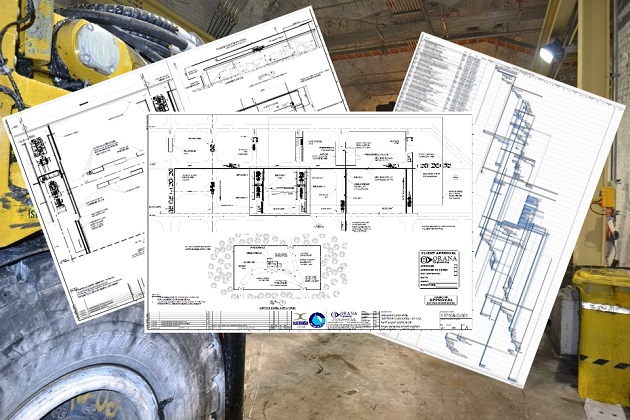

Underground Workshop Concept Design

Due to expanding operations, Glencore's Oaky North underground operations saw benefit in having an underground workshop and refueling stations to reduce vehicle travel times and increase efficiencies. Orana Engineering was engaged to provide concept design and estimating assistance for project approval.

From communications with our client, Orana Engineering prepared concept general arrangement drawings for consideration. Based on these concept design drawings, a project capital estimate and project schedule were prepared for Oaky North.

From the information presented by Orana Engineering, the client could accurately consider whether the underground workshop was feasible and ensure that appropriate budgeting and project planning was completed at the concept design phase to improve confidence in the project prior to execution.

Wall Kit Drafting

BHP Billiton's Cannington Mine is a significant underground silver and lead mining operation in Western Queensland. Following completion of ore extraction from each stope, paste backfill is used to fill the open void and stabilise the area. This is achieved by constructing a fill wall which provides stability for areas being backfilled, eliminates intrusion, and allows a higher density of backfill.

Wall construction kits supplied to Cannington contained no documentation detailing the kit components. BHP Billiton engaged Orana Engineering to confirm the components in these kits.

Using measurements and sketches obtained from site, Orana Engineering design drafting personnel utilised AutoCAD to create a drawing set detailing the components required and fabrication details for each construction kit.

Yokogawa DCS Upgrade

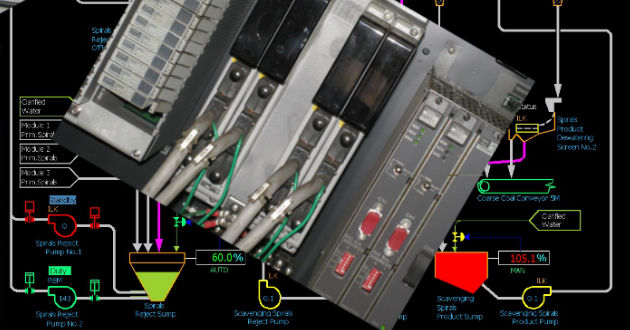

Since 2005, Orana Engineering has provided 24/7 support for Glencore's Oaky Creek Coal control systems. At the CHPP a Yokogawa DCS installed in 1998 is used as the primary control system. With existing CentumCS Unix software no longer supported by Yokogawa, it was essential to complete an upgrade to the CentumCS3000 system.

Orana Engineering developed conversion tools to allow configuration data to be extracted from the CentumCS Unix platform and imported into the CentumCS3000 environment. These tools provided efficiency and accuracy for the conversion and delivered a significant cost saving.

The quality of conversion tools and simulation programs developed by Orana Engineering resulted in highly efficient site commissioning, completed without plant downtime.