Engineering Services

Orana Engineering offers a complete range of engineering services and design drafting services through the in-house expertise of our qualified and experienced team. As an engineering consultancy working in mechanical, electrical, structural and control systems engineering, Orana Engineering is experienced in detailed design engineering for the coal mining, metalliferous mining, oil and gas and heavy industries.

Orana Engineering's engineering services include, but are not limited to the preparation and delivery of:

- Budget Estimates;

- Detailed Engineering Designs and Calculations;

- Engineering Investigations and Audits;

- Engineering Specifications;

- Engineering Studies;

- Functional Descriptions;

- Hazardous Area Designs;

- Project Management;

- Project Scheduling;

- Scopes of Works;

- System Modelling;

- Tailored Control System Training Courses; and

- Technical Evaluations.

For projects consisting of civil engineering design, Orana Engineering has the resources to fulfill the project's requirements via in-house expertise and established and proven relationships with external companies.

Our people are core to the quality of engineering services offered and our team is both technically qualified and practically experienced. Our staff possess RPEQ certifications, CPEng qualifications and hands-on site backgrounds. We deliver a unique approach to engineering services and engineering design. Having operations and maintenance engineering backgrounds, the experience of Orana Engineering personnel make them better able to understand the complexities and scheduling challenges that are often involved in performing engineering activities for continuous and remote operations. This results in a more cost and time efficient solution for the client.

The unique combination of our experience, wide-ranging capabilities and practical approach ensures Orana Engineering delivers engineering services that:

- Perform - Site experience and trade backgrounds mean our engineering designs are practical and considerate of site factors that can complicate a project, our designs are not just good on paper;

- Are simple - Our clients have access to a full range of engineering services under one roof, building a relationship with one engineering firm that can manage everything from your design drafting, drawing revisions and drawing management through to complete project management or Client Engineer assistance;

- Instill confidence - Working with an experienced firm gives our clients confidence and allows them to be informed to make decisions; and

- Are efficient - Outsourcing engineering services can assist with site resourcing, freeing up site personnel and ensuring that you have a qualified expert dedicating the right amount of time to the required task.

Contact us today to see how Orana Engineering’s qualified and experienced personnel can add value to all your engineering service requirements.

Orana Engineering Design Drafting

Flotation Cell Upgrade

To increase the efficiency of their concentrator, Eloise Copper Mine enlisted Orana Engineering to provide engineering and design assistance with installation of three copper concentrate scavenger cells within the existing plant. 3D models created by Orana Engineering designers were used to visually communicate solutions for new and existing equipment locations and structure arrangements. Detailing of these concept models enabled Orana Engineering to identify key tie-in locations within the plant for survey during the detailed design phase. A multidisciplinary approach during detailed design ensured improved efficiency, with brownfield engineering challenges in relocating / connecting to existing equipment successfully achieved. Upon design completion the client was provided with an installation drawing set and scope of work.

Read moreGold Slurry Sampler

Orana Engineering was engaged to design new sampling equipment for improved sampling effectiveness at Carpentaria Gold’s Ravenswood operations. A site visit was undertaken by Orana Engineering design staff to accurately record critical data. This enabled designers to produce a detailed 3D model which was used extensively during interactions with the client and ensured a fluent understanding of the project scope by both parties throughout the design process. Orana Engineering was able to integrate new sampling equipment into the existing plant whilst minimising any impact on the operation. Various challenges were overcome with the result being successful delivery of drawings for fabrication and installation of equipment, allowing improved sampling and production reconciliation whilst minimising impact to operations.

Read moreHeavy Vehicle Washdown Facility

MMG's Karumba Port Facility engaged Orana Engineering to design a heavy vehicle washdown facility to assist with management of concentrate for site vehicles and machinery. The time frame was short due to operational requirements, such that Orana Engineering worked from concept to IFC drawings in just seven days. The design needed to accommodate a number of different vehicles from fully laden container trailers to a 30 tonne forklift, whilst also ensuring ease of facility maintenance and capture of runoff for environmental compliance. Concept sketches were prepared, from which a detailed design was developed to meet client requirements. Through effective communication with the client Orana Engineering was able to deliver the design in a compressed timeline, to specification and budget.

Read moreInner Bypass Valves

Orana Engineering was engaged by MMG's Century Mine to design an upgrade within the concentrator for increased flow from a flotation cell to a tailings trough. Orana Engineering conducted a concept investigation of available options to increase the flow rate. Results were presented for a range of design and operating conditions, and a preferred option was selected for detailed design. Orana Engineering design staff created a 3D model of the new pipeline using Autodesk Inventor. The 3D model was used to produce fabrication drawings for pipe supports, new platform and new pipe bridge. Drawings also included isometric pipe spool drawings and revised P&ID drawings.

Read moreJaw Crusher Platform

The maintenance department of Eloise Copper Mine contacted Orana Engineering with a requirement for design of an access platform for their jaw crusher, including engineering certification and drafting. The client provided site measurements and a basic concept of the design they were looking for. Being a brownfield engineering project, the design had to consider the surrounding area and existing structures to minimise modifications. Autodesk Inventor was used to create a basic 3D model of the area. Once the physical data was established the detailed design of the platform was able to be performed efficiently. Orana Engineering was able to produce both detailed shop drawings for fabrication and site installation drawings, all of which were provided with structural engineering certification.

Read moreMG07 Conveyor – Civil Design

Carborough Downs is an underground operation utilising conveyors to transport mined coal to the surface. As new longwall headings are mined, new conveyor installations are also required. During installation of conveyors in an underground environment it is vital that the civil design is detailed accurately as this is the basis for locating and installing conveyor equipment. Orana Engineering was engaged to complete this design and used AutoCAD to develop a civil design that met the client’s constraints and constructability requirements. From this design Orana Engineering produced a drawing set detailing civil aspects of the conveyor design, including floor / rib trimming, equipment hold-down details, configuration of concrete reinforcing and overall grade of concrete.

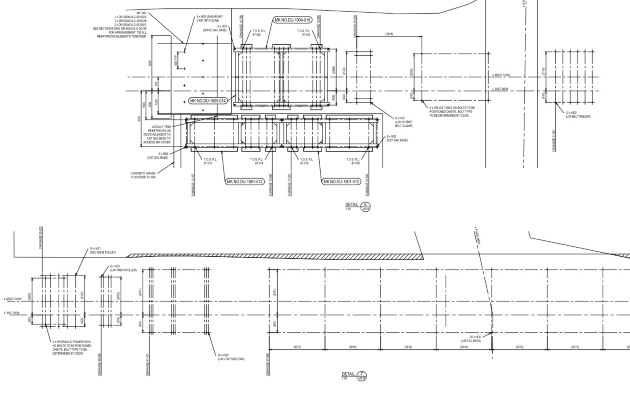

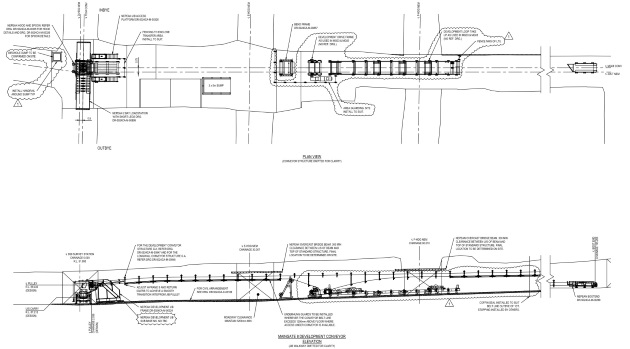

Read moreMG08 Development Conveyor

Carborough Downs Coal Mine is an underground operation utilising conveyors to transport mined coal to the surface for processing. As operations progress and new longwall headings are mined, new conveyor installations are also required. Orana Engineering was engaged to design a new longwall drive-head chamber and conveyor installation, initially providing a drawing set detailing required drive-head chamber dimensions to suit the conveyor installation. Using AutoCAD, a civil design and conveyor equipment arrangement was produced. The conveyor design had to consider several constraints, including available equipment, transfer tie-in to existing trunk conveyor, maintenance access, drainage, minimum clearances and belt curves. Upon layout approval, AutoCAD drawings were produced detailing civil and mechanical design aspects, enabling site engineers to complete installation with efficiency while ensuring regulatory compliance.

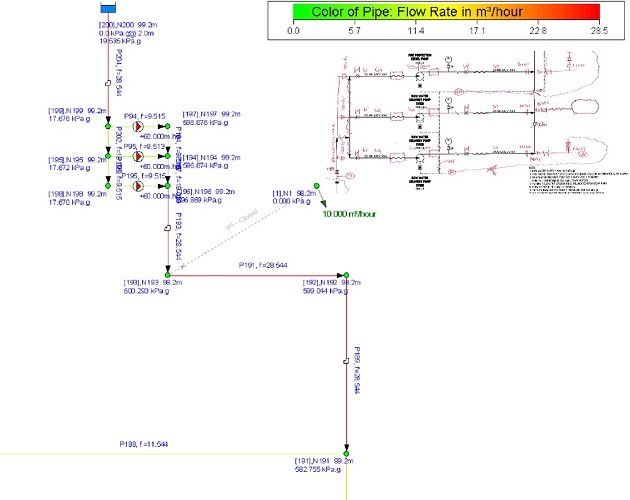

Read moreMIA Services Audit

Orana Engineering was requested to complete an audit of water and wastewater services at BMA’s Blackwater Mine. The audit was to determine whether new go-line infrastructure would adversely impact the existing mine industrial area services, and whether additional infrastructure or upgrades were required. Data collected from site by Orana Engineering was used to prepare a hydraulic model for each service. Modelling results, findings and recommendations were included in a detailed report outlining the capacity and utilisation of existing services to quantify available system capacity for the proposed new buildings. Additionally, Orana Engineering’s drawing revision services were utilised to formally revise site P&IDs to As Built, incorporating mark-ups made during the site visit.

Read moreMIBC & Diesel Upgrade

The purpose of the Reagent System Upgrade at Oaky Creek was installation of new reagent storage tanks, discharge / delivery pumping systems and automated flow control distribution manifolds for the delivery of each reagent to the nominated process connections. Orana Engineering performed mechanical, electrical and control systems design, drafting and engineering for the project. The primary deliverables included scope of works, construction drawings, functional specification, BOM, spares lists and equipment / instrument data sheets. Orana Engineering managed the onsite commissioning of the system and provided a system handover to operations for implementation. An Operation & Maintenance Manual and Hazardous Area Dossier were provided on project completion.

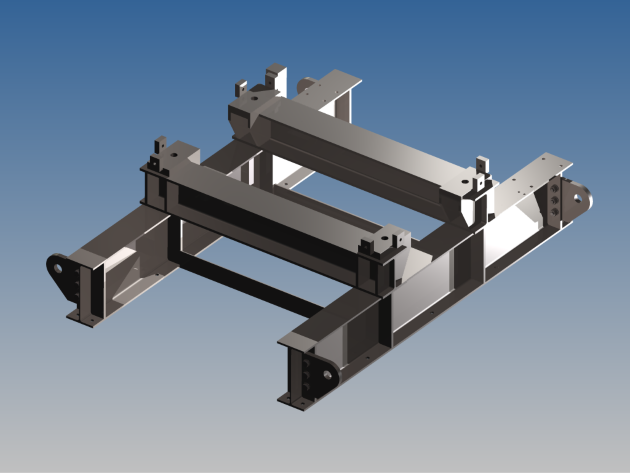

Read moreMill Gear Box Frame

The IMT project team at MMG’s Century Zinc operations enlisted the assistance of Orana Engineering to produce a set of fabrication drawings for an existing gear box frame that required replacing. The frame had been in operation for some time, however there were no detailed drawings available for construction of a replacement unit. The design staff at Orana Engineering created a detailed 3D model using client-supplied photos and sketches, enabling designers to produce 2D fabrication drawings for approval. A review of the drawings was conducted by the client to confirm the layout and accurate alignment with the existing installation on site. Following minor adjustments, As-Built status drawings were reissued to the client, accurately capturing detail of the existing frame.

Read more