Engineering Services

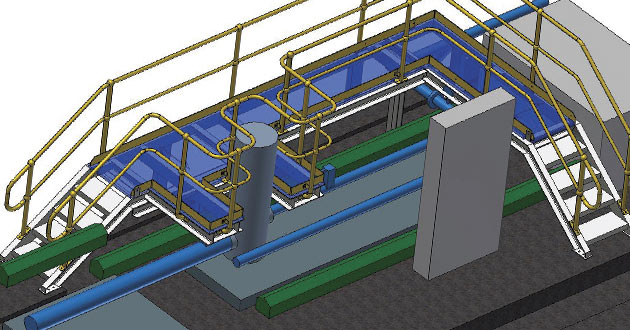

Orana Engineering offers a complete range of engineering services and design drafting services through the in-house expertise of our qualified and experienced team. As an engineering consultancy working in mechanical, electrical, structural and control systems engineering, Orana Engineering is experienced in detailed design engineering for the coal mining, metalliferous mining, oil and gas and heavy industries.

Orana Engineering's engineering services include, but are not limited to the preparation and delivery of:

- Budget Estimates;

- Detailed Engineering Designs and Calculations;

- Engineering Investigations and Audits;

- Engineering Specifications;

- Engineering Studies;

- Functional Descriptions;

- Hazardous Area Designs;

- Project Management;

- Project Scheduling;

- Scopes of Works;

- System Modelling;

- Tailored Control System Training Courses; and

- Technical Evaluations.

For projects consisting of civil engineering design, Orana Engineering has the resources to fulfill the project's requirements via in-house expertise and established and proven relationships with external companies.

Our people are core to the quality of engineering services offered and our team is both technically qualified and practically experienced. Our staff possess RPEQ certifications, CPEng qualifications and hands-on site backgrounds. We deliver a unique approach to engineering services and engineering design. Having operations and maintenance engineering backgrounds, the experience of Orana Engineering personnel make them better able to understand the complexities and scheduling challenges that are often involved in performing engineering activities for continuous and remote operations. This results in a more cost and time efficient solution for the client.

The unique combination of our experience, wide-ranging capabilities and practical approach ensures Orana Engineering delivers engineering services that:

- Perform - Site experience and trade backgrounds mean our engineering designs are practical and considerate of site factors that can complicate a project, our designs are not just good on paper;

- Are simple - Our clients have access to a full range of engineering services under one roof, building a relationship with one engineering firm that can manage everything from your design drafting, drawing revisions and drawing management through to complete project management or Client Engineer assistance;

- Instill confidence - Working with an experienced firm gives our clients confidence and allows them to be informed to make decisions; and

- Are efficient - Outsourcing engineering services can assist with site resourcing, freeing up site personnel and ensuring that you have a qualified expert dedicating the right amount of time to the required task.

Contact us today to see how Orana Engineering’s qualified and experienced personnel can add value to all your engineering service requirements.

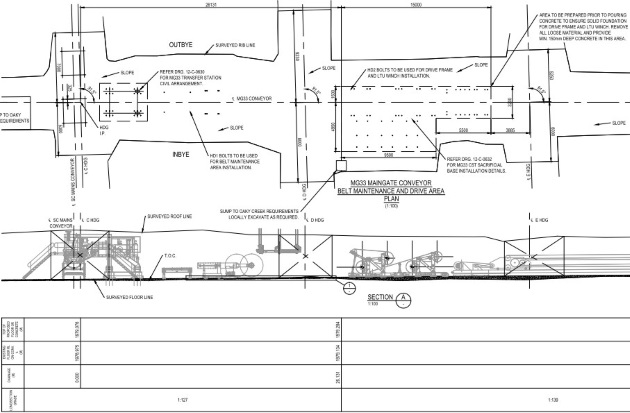

Orana Engineering Design Drafting

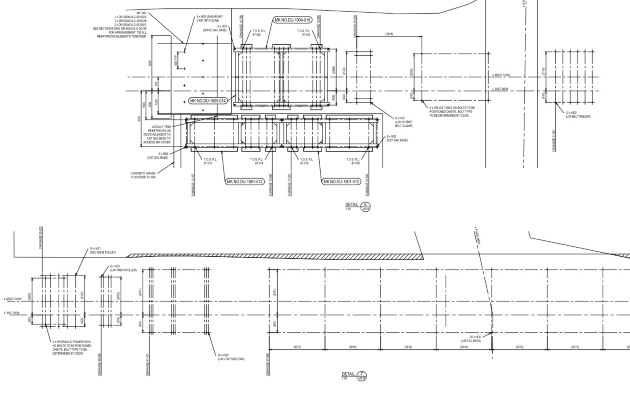

UG Conveyor Installations - MG Mechanical Installation

Detailing the installation of mechanical equipment and conveyor structures is one of the final steps for completing a maingate drive-head design. Installations designed by Orana Engineering for Glencore’s Oaky No.1 underground coal mine included detailing drive arrangements, transfer stations, take-up units, maintenance equipment and the overhead structures supporting the carry belt.

Mechanical design must consider a number of factors, including meeting the required operating capabilities, allowing for unimpeded access along travel roads and maintaining minimum belt curves. Often equipment is relocated from previous installations with minor modifications in transfer angle and number of drives. Orana Engineering has developed unique methods for completing this type of design, enabling us to keep total costs down for our clients.

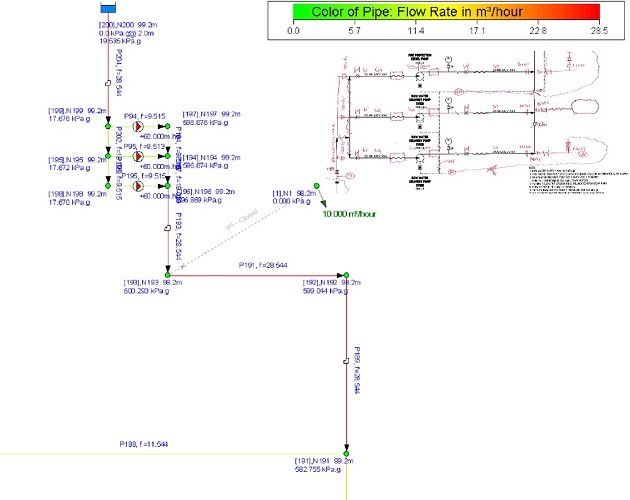

Compressed Air Upgrade

Anglo American’s Moranbah North CHPP operations personnel contacted Orana Engineering to investigate problems with low compressed air pressures and air flow rates. There were additional concerns regarding compressor reliability associated with the operation of equipment, valves, tooling, maintenance and instrumentation.

Orana Engineering conducted an onsite investigation which included preparing as-built drawings of the high-level compressed air distribution network within the CHPP. A review of historic transmitter data for the system was also carried out to identify issues and bottlenecks. System performance was also reviewed against site-checked pressures and engineering flow rate and pressure loss.

Upon conclusion of the investigation a summary of findings and recommendations was presented to the client encompassing as-built drawings, calculations, a summary of works and recommendations for resolution.

Combabula Bore Pump

Prime Pump Company was contracted by Origin Energy and Laing O’Rourke to supply an upgraded bore pumping system at Origin’s Combabula site. RIE Services was contracted by Prime Pump Company to supply and install electrical components for the upgrade, with Orana Engineering subsequently engaged by RIE Services to complete a fault protection study on the new installation.

Using SKM Power Tools for Windows software and manual calculation techniques for verification, together with information from RIE and Prime Pump Company, Orana Engineering produced an HV/LV model calculating fault levels and completing a protection co-ordination study.

From the study it was recommended a new circuit breaker be introduced to protect the transformer, variable speed drive and supply cables.

22M Flyover Conveyor

Oaky Creek Coal engaged Orana Engineering to perform electrical and control system design aspects of a 22M Flyover Conveyor to provide an interface between two existing conveyor systems.

Orana Engineering’s brownfield engineering expertise was drawn upon to resolve complexities in interfacing two different coal streams, powered from separate substations and controlled from independent process control systems. Should one system need to be shutdown it was necessary that the other system was not impacted.

The electrical engineering scope included powering the conveyor and transfer systems and providing lighting designs and power distribution. Control system engineering included selection and specification of instrumentation, specification of control system hardware and development of a functional specification.

Ball Mill No. 2 Recommissioning

Eloise Copper Mine required recommissioning of their No.2 Ball Mill. During recommissioning it was identified that a means of relocating grinding media to the feed chute needed to be designed and engineered, with RPEQ certification. Orana Engineering was contacted to assist and a monorail, complete with electric hoist and trolley, was identified as being the practical solution.

Challenges presented themselves while locating the monorail within the existing structure, however Orana Engineering was able work within the constraints of the existing structure to meet client requirements. All elements of the structural engineering review and design of the monorail to were taken into account.

RPEQ certified fabrication and installation drawings were produced, ensuring the upgraded structure was fit for purpose.

CHPP Conveyor Capacity Audit

Vale at Carborough Downs Coal Mine required quantifying of current and possible future capacities of product conveyors at their coal processing plant in Central Queensland and high level recommendations to achieve increased plant tonnages.

Orana Engineering completed an initial site visit to gather the necessary information for a review of each of the conveyors. Engineering checks were completed to identify bottle-necks in the conveyor design such as motor power, drive equipment, belt curves, GTU mass, belt speed, belt capacity, belt tensions and electrical supply.

Orana Engineering issued a detailed report at completion of the study and provided concept level equipment modification recommendations for tonnage ranges advised by Carborough Downs Coal Mine.

Crusher Circuit Upgrade

Eloise Copper Mine purchased a Metso dual deck vibrating screen to replace an existing smaller screen and a second Omnicone cone crusher to provide a secondary crushing circuit for increased production and efficiency. Orana Engineering was engaged to develop a design solution and detailed drawings for the secondary crushing circuit which utilised as much existing equipment as possible.

Orana Engineering was able to provide an efficient, practical design solution while minimising the associated design costs to provide site personnel with information required to refurbish and install the conveyor equipment necessary for the crushing circuit.

Orana Engineering successfully completed the design within a tight project time frame and produced in excess of 100 detailed drawings.

Cyanide Tank Upgrade

Carpentaria Gold identified that bunding around their Ravenswood cyanide storage tank was inadequate. Sodium Cyanide, used in the gold recovery process, is potentially lethal to humans and animals and detrimental to the environment. It is necessary to ensure it can be safely contained in an emergency.

Orana Engineering provided an innovative solution comprising a smaller tank fitted inside the existing tank. The design minimised loss of storage capacity by providing a smaller tank for primary storage whilst maintaining the existing external tank to act as the bund.

Utilising the existing tank as a bund, Orana Engineering delivered a design that met the client brief while re-using the majority of major tie-in points and providing improved access for maintenance.

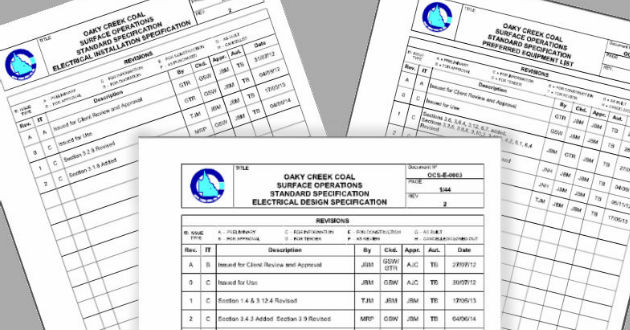

Electrical Specifications

For site consistency of electrical design and installation standards and compliance with Australian standards and legislation, Glencore Oaky Creek Coal engaged Orana Engineering to prepare new site electrical specifications. The scope combined existing site specifications and practices and, where applicable, incorporated them into the new specifications. These specifications included:

- Electrical Design

- Electrical Installation

- Preferred Electrical Equipment List

- Site Equipment Numbering

- Drawing Management

Orana Engineering’s extensive knowledge of Queensland mine sites and long-standing experience at Oaky Creek enabled specifications to be produced cost effectively and fully inclusive of site specific details. Orana Engineering continues to maintain these documents for Oaky Creek Coal, ensuring that latest versions are readily available to site personnel via Oaky Creek’s drawing management system.

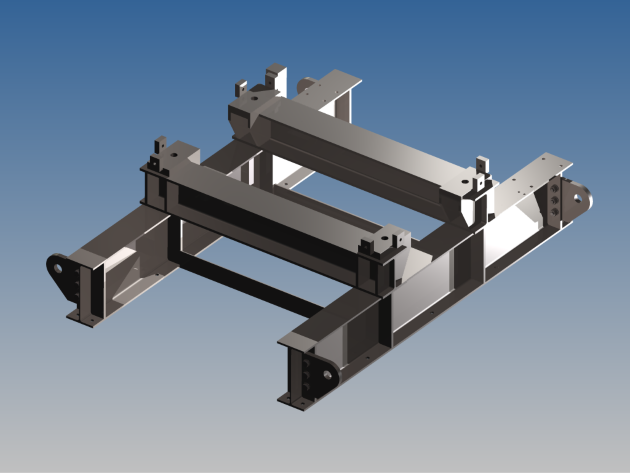

FB-028 Tank Lifting Beam

During an upgrade to the concentrator at MMG’s Century Mine, Orana Engineering was engaged to design a lifting beam for installation of a new flotation cell. The lifting beam design was to provide adaptation between lifting points on the tank and the crane, providing stability during lifting and protecting the integrity of the tank.

Structural considerations involved hand calculations and modelling in SPACE GASS based on client requirements and relevant Australian Standards. Orana Engineering's design utilised available structural members on site, providing cost benefits to the client.

Orana Engineering design staff created a 3D model in Autodesk Inventor, producing a fabrication drawing for the beam which also detailed the sling configuration for use during the lifting process.

Fire System Audit

BMA Gregory Crinum engaged Orana Engineering to perform an audit and inspection of the Crinum underground mine surface fire water system with respect to providing adequate pressure and flow for the Crinum North conveyor system and stockpile conveyor.

Orana Engineering completed a site inspection and audit against the design drawings, with site-verified information then used for compliance assessment in line with Australian Standards. The audit included in-depth assessment of the fire water system to Australian, BMA and site Fire Management Standards. Hydraulic modelling of the fire system was also undertaken to validate existing pressure measurements.

Orana Engineering was able to make recommendations regarding compliance and system hydraulic performance, which assisted BMA in improving system capacity.

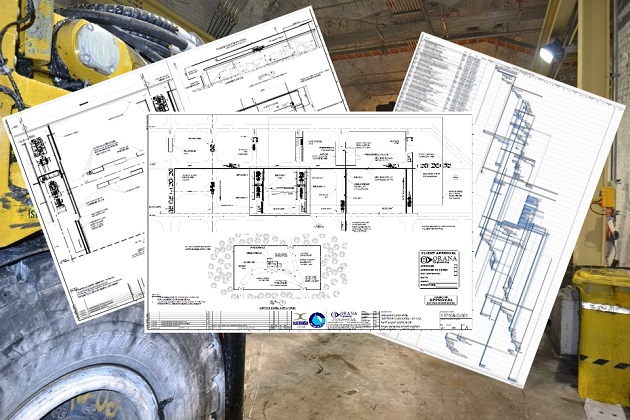

Flotation Cell Upgrade

To increase the efficiency of their concentrator, Eloise Copper Mine enlisted Orana Engineering to provide engineering and design assistance with installation of three copper concentrate scavenger cells within the existing plant.

3D models created by Orana Engineering designers were used to visually communicate solutions for new and existing equipment locations and structure arrangements. Detailing of these concept models enabled Orana Engineering to identify key tie-in locations within the plant for survey during the detailed design phase.

A multidisciplinary approach during detailed design ensured improved efficiency, with brownfield engineering challenges in relocating / connecting to existing equipment successfully achieved. Upon design completion the client was provided with an installation drawing set and scope of work.

Gold Slurry Sampler

Orana Engineering was engaged to design new sampling equipment for improved sampling effectiveness at Carpentaria Gold’s Ravenswood operations.

A site visit was undertaken by Orana Engineering design staff to accurately record critical data. This enabled designers to produce a detailed 3D model which was used extensively during interactions with the client and ensured a fluent understanding of the project scope by both parties throughout the design process.

Orana Engineering was able to integrate new sampling equipment into the existing plant whilst minimising any impact on the operation. Various challenges were overcome with the result being successful delivery of drawings for fabrication and installation of equipment, allowing improved sampling and production reconciliation whilst minimising impact to operations.

Heavy Vehicle Washdown Facility

MMG's Karumba Port Facility engaged Orana Engineering to design a heavy vehicle washdown facility to assist with management of concentrate for site vehicles and machinery. The time frame was short due to operational requirements, such that Orana Engineering worked from concept to IFC drawings in just seven days.

The design needed to accommodate a number of different vehicles from fully laden container trailers to a 30 tonne forklift, whilst also ensuring ease of facility maintenance and capture of runoff for environmental compliance.

Concept sketches were prepared, from which a detailed design was developed to meet client requirements. Through effective communication with the client Orana Engineering was able to deliver the design in a compressed timeline, to specification and budget.

Inner Bypass Valves

Orana Engineering was engaged by MMG's Century Mine to design an upgrade within the concentrator for increased flow from a flotation cell to a tailings trough.

Orana Engineering conducted a concept investigation of available options to increase the flow rate. Results were presented for a range of design and operating conditions, and a preferred option was selected for detailed design.

Orana Engineering design staff created a 3D model of the new pipeline using Autodesk Inventor. The 3D model was used to produce fabrication drawings for pipe supports, new platform and new pipe bridge. Drawings also included isometric pipe spool drawings and revised P&ID drawings.

Jaw Crusher Platform

The maintenance department of Eloise Copper Mine contacted Orana Engineering with a requirement for design of an access platform for their jaw crusher, including engineering certification and drafting. The client provided site measurements and a basic concept of the design they were looking for.

Being a brownfield engineering project, the design had to consider the surrounding area and existing structures to minimise modifications. Autodesk Inventor was used to create a basic 3D model of the area. Once the physical data was established the detailed design of the platform was able to be performed efficiently.

Orana Engineering was able to produce both detailed shop drawings for fabrication and site installation drawings, all of which were provided with structural engineering certification.

MG07 Conveyor – Civil Design

Carborough Downs is an underground operation utilising conveyors to transport mined coal to the surface. As new longwall headings are mined, new conveyor installations are also required. During installation of conveyors in an underground environment it is vital that the civil design is detailed accurately as this is the basis for locating and installing conveyor equipment.

Orana Engineering was engaged to complete this design and used AutoCAD to develop a civil design that met the client’s constraints and constructability requirements. From this design Orana Engineering produced a drawing set detailing civil aspects of the conveyor design, including floor / rib trimming, equipment hold-down details, configuration of concrete reinforcing and overall grade of concrete.

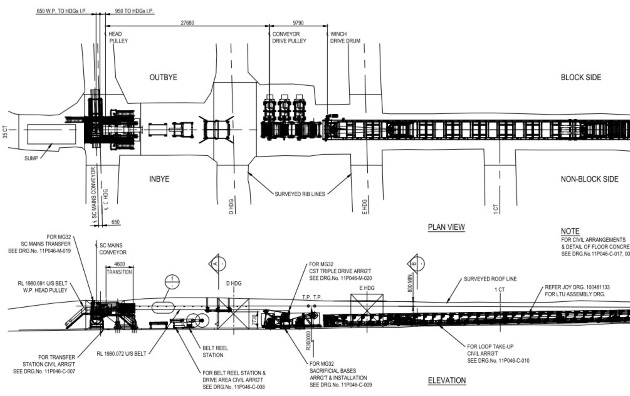

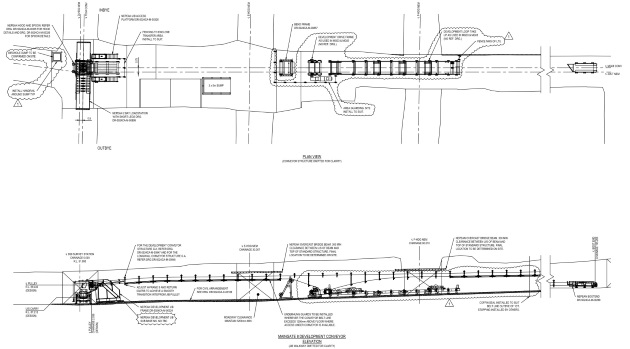

MG08 Development Conveyor

Carborough Downs Coal Mine is an underground operation utilising conveyors to transport mined coal to the surface for processing. As operations progress and new longwall headings are mined, new conveyor installations are also required.

Orana Engineering was engaged to design a new longwall drive-head chamber and conveyor installation, initially providing a drawing set detailing required drive-head chamber dimensions to suit the conveyor installation.

Using AutoCAD, a civil design and conveyor equipment arrangement was produced. The conveyor design had to consider several constraints, including available equipment, transfer tie-in to existing trunk conveyor, maintenance access, drainage, minimum clearances and belt curves.

Upon layout approval, AutoCAD drawings were produced detailing civil and mechanical design aspects, enabling site engineers to complete installation with efficiency while ensuring regulatory compliance.

MIA Services Audit

Orana Engineering was requested to complete an audit of water and wastewater services at BMA’s Blackwater Mine. The audit was to determine whether new go-line infrastructure would adversely impact the existing mine industrial area services, and whether additional infrastructure or upgrades were required.

Data collected from site by Orana Engineering was used to prepare a hydraulic model for each service. Modelling results, findings and recommendations were included in a detailed report outlining the capacity and utilisation of existing services to quantify available system capacity for the proposed new buildings. Additionally, Orana Engineering’s drawing revision services were utilised to formally revise site P&IDs to As Built, incorporating mark-ups made during the site visit.

MIBC & Diesel Upgrade

The purpose of the Reagent System Upgrade at Oaky Creek was installation of new reagent storage tanks, discharge / delivery pumping systems and automated flow control distribution manifolds for the delivery of each reagent to the nominated process connections.

Orana Engineering performed mechanical, electrical and control systems design, drafting and engineering for the project. The primary deliverables included scope of works, construction drawings, functional specification, BOM, spares lists and equipment / instrument data sheets.

Orana Engineering managed the onsite commissioning of the system and provided a system handover to operations for implementation. An Operation & Maintenance Manual and Hazardous Area Dossier were provided on project completion.

Mill Gear Box Frame

The IMT project team at MMG’s Century Zinc operations enlisted the assistance of Orana Engineering to produce a set of fabrication drawings for an existing gear box frame that required replacing. The frame had been in operation for some time, however there were no detailed drawings available for construction of a replacement unit.

The design staff at Orana Engineering created a detailed 3D model using client-supplied photos and sketches, enabling designers to produce 2D fabrication drawings for approval. A review of the drawings was conducted by the client to confirm the layout and accurate alignment with the existing installation on site. Following minor adjustments, As-Built status drawings were reissued to the client, accurately capturing detail of the existing frame.

Onsite Accommodation Camp Services

Orana Engineering was engaged by Oaky Creek Coal to assist in design and construction of onsite camp accommodation, including an HV substation for power and potable water supply.

The brief included mechanical, electrical and control systems design, drafting and engineering for the project. Deliverables included scope of works, construction drawings, functional specification, drawing and equipment registers, commissioning and operating spares lists and equipment and instrument data sheets.

Orana Engineering provided PLC configuration and commissioning assistance for pump control, acted as Client Representative during construction, managed onsite commissioning of the system, and provided a handover to operations for implementation.

Operation & Maintenance Manuals for potable water storage and the HV substation were provided upon completion.

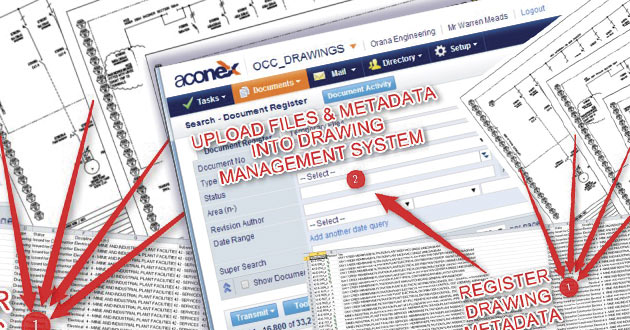

Process Water RO Plant Vendor Drawing Registration

Following commissioning of their Process Water Reverse Osmosis (RO) Plant, Oaky Creek Coal received approximately 150 electrical drawings from the vendor. To provide site personnel with access to the drawings, Oaky Creek engaged Orana Engineering to register these within their existing drawing management system.

There are many drawing management systems and tools on the market and Orana Engineering has the capabilities and resources to utilise whatever system is preferred by a client. Oaky Creek Coal sets a very high standard in the industry for the maintenance of drawings and in real terms realises the significant cost benefits that good drawing management delivers in enabling site personnel to perform effectively and safely.

SAG Mill Cover

BHP Billiton Cannington Mine, is a significant miner and exporter of silver and lead concentrate. Orana Engineering was engaged to provide workshop fabrication drawings for a replacement cover to address corrosion issues around flanges and access openings on the existing SAG mill trommel sump cover.

Following a site visit to obtain measurements, photos, drawings and documentation, the Orana Engineering design drafting team created a detailed 3D model of the existing structure incorporating new components to produce a set of detailed shop fabrication drawings, while also revising multiple existing drawings. These drawings were reissued for construction after receiving client approval.

The new cover sections and access panels improved the safety of trommel operation while also reducing inspection and maintenance time.

Sewage Treatment Plant Refurbishment

To increase productivity and maintain compliance with legislative standards, Glencore Oaky Creek Coal employed the services of Orana Engineering to design and manage the electrical aspects of an upgrade to their existing sewage treatment plant.

The project was managed on-site by others, with Orana Engineering providing electrical engineering, design, project management and construction / commissioning assistance.

Upon completion of installation, Orana Engineering updated all drawings to reflect any changes made, thus providing Glencore Coal with as-built drawings which will make any future maintenance or fault-finding work more efficient and cost effective, as well as providing legislative compliance.

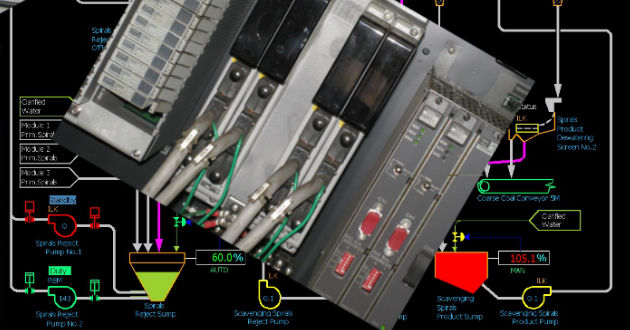

Site DCS Support

The CHPP at Oaky Creek Coal utilises a Yokogawa Distributed Control System for control and monitoring of their operation. The system incorporates Yokogawa’s OPC server and Exaquantum data historian. OCC utilises multiple Programmable Logic Controllers for specific operational purposes, with a number of PLC's interfaced back to the DCS for control and monitoring functions.

Since 2005, Orana Engineering has provided 24/7 support for Oaky Creek’s control system. Day to day support is provided by remote access, which is cost effective and highly responsive. Additionally, onsite support for hardware solutions and commissioning of larger projects is provided as required.

Tank Farm Upgrade

Melbourne Bio Diesel’s James Cook University research facility required an elevated level area for installation of fresh sea water storage tanks. Orana Engineering was requested to design a solution that increased efficiency with tank drainage and improved safety around the tanks.

A site visit was performed to gather measurements of the nominated tank farm area. This included identifying trees requiring removal and determining required tank heights and current ground levels. From the information gathered Orana Engineering used AutoCAD to model ground levels and the amount of fill required to lift tanks to a suitable level for gravity drainage. The design incorporated a conical base on each tank for drainage and the introduction of buried control valves accessible via covered pits.

Tank Static Line

Management at Carpentaria Gold’s Ravenswood Operation enlisted Orana Engineering to design a fall arrest system that could be easily removed and repositioned above multiple leach tanks, allowing for safe removal and servicing of tank agitators.

From a site visit, Orana Engineering identified the need for an arrangement that could be easily disassembled and relocated to each leach tank. The design was challenging due to the varying nature of access structure members above tanks.

Orana Engineering designers proposed an assembly utilising a common set of supporting columns with struts of varying lengths depending on the work location. A full set of shop fabrication and assembly drawings were issued with the final design providing safety for personnel working above open tanks.

Tippler Refurbishment Feasibility

Glencore Port Operations in Townsville operate an export facility for minerals concentrate and refined copper within the Port of Townsville precinct. The concentrate in-loading rotaside tippler was identified as being at end of life and a feasibility study was commissioned to review a like-for-like replacement option for refurbishment of the tippler.

To facilitate feasibility-level costing, Orana Engineering was asked to provide electrical engineering and mechanical engineering assistance with provision of a concept design for the proposed refurbishment and upgrade.

By working closely with Glencore, and other consultants engaged on the project, Orana Engineering was able to contribute as part of a collective "owners engineering team" to the feasibility assessment of a significant engineering project in the Townsville Region.

TK102 Bypass Piping

When tasked with a major repair to one of their leaching tanks, personnel at Carpentaria Gold's Ravenswood Operations enlisted the assistance of Orana Engineering to develop a solution that would allow process operations to continue whilst leaching tank TK102 was out of service.

A site visit and discussions with the client suggested the installation of a bypass line around TK102. By utilising site information, Orana Engineering designerswere able to detail a new bypass line through the existing processing plant area. This involved minor modification of existing structural steel and addition of pipe supports for the new HDPE bypass pipeline.

Bypass piping was successfully installed during normal operation with only tie-ins needing to be installed during a single shut down.

Treated Water Boost Pumps

Oaky Creek Coal uses an onsite reverse osmosis plant to provide treated recycled water to various site operations. An opportunity was identified to use this recycled water for supply to critical equipment such as horizontal belt filters, thereby improving equipment water quality, reducing equipment downtime and lowering maintenance requirements.

Orana Engineering reviewed the performance of two existing boost pumps intended to provide high pressure treated water to a new horizontal belt filter. Hydraulic modelling was performed to predict future demand and thus determine the suitability of the existing pumps for use in the new application.

Orana Engineering also prepared a control philosophy for use by systems engineers to ensure safe operation of the pumps under all operating conditions.

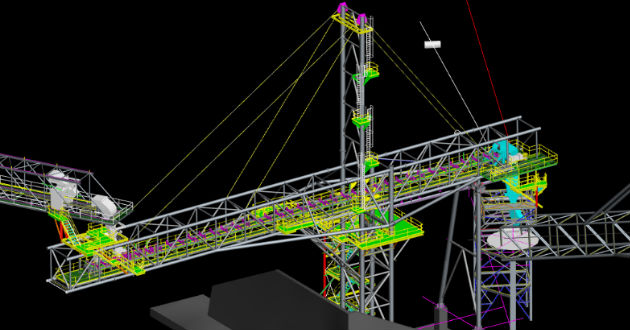

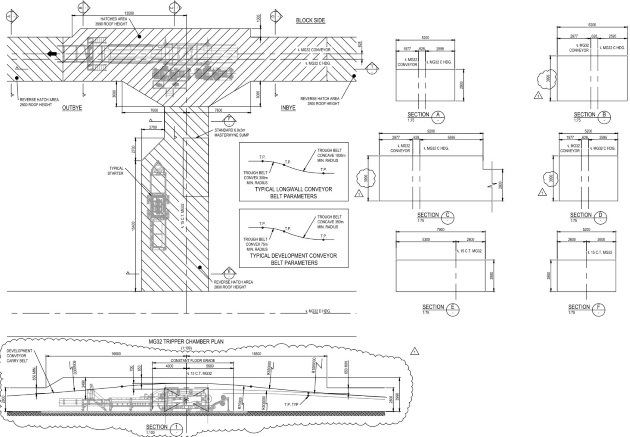

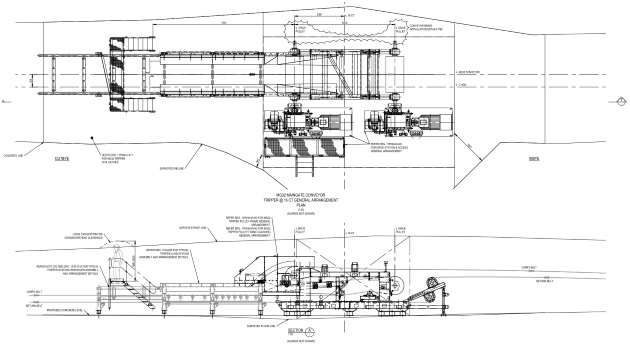

UG Conveyor Installations – MG32 Tripper Chamber

At Glencore’s Oaky No.1 underground coal mine, transportation of vast quantities of coal over long distances requires significant power. Often drive-head power is insufficient or constrained by allowable belt tension and an additional drive or power source is required to meet operating capacity. Additional power is commonly sourced from a driven conveyor tripper installed along the conveyor with appropriate excavation for the tripper.

Using the client’s existing mine plan to position the new tripper chamber, Orana Engineering design drafting personnel worked with site engineers to assess required chamber dimensions while simultaneously minimising the excavation of material.

Orana Engineering used AutoCAD to produce a drawing set detailing the mining required, and an overlay showing future equipment installations within the new chamber.

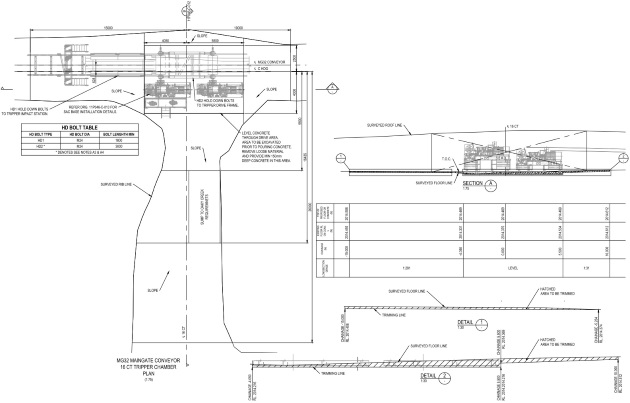

UG Conveyor Installations – MG32 Tripper Civil Design

Engineers at Glencore’s Oaky No. 1 underground coal mine engaged Orana Engineering to determine civil work requirements to install tripper equipment on the MG32 longwall conveyor. On completion of chamber mining, finished surfaces (rib and floor) may require modification for the installation of conveyor tripper equipment. The civil design must determine concrete grades for drainage, safe access and reinforcing for conveyor equipment, while minimising trimming and concrete required.

Manipulating “as-cut” survey data using AutoCAD, Orana Engineering design staff could accurately determine where tripper equipment could be installed with minimal trimming and concreting. A drawing set was produced detailing civil aspects of the tripper design, including chamber trimming, equipment mounting locations, configuration of reinforcing and relative concrete levels for drainage.

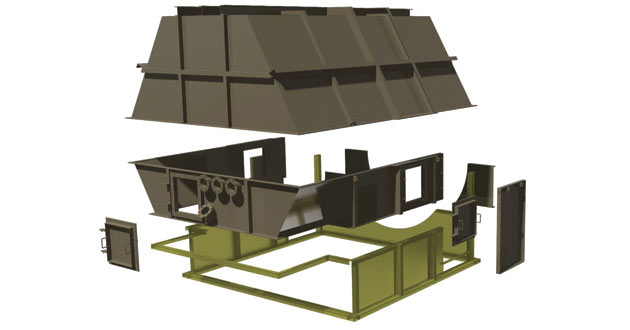

UG Conveyor Installations – MG32 Tripper Mechanical Design

Orana Engineering was engaged by Glencore to design and install a detailed arrangement of tripper drives, brakes, pulley frame and load station for the MG32 conveyor at its Oaky No.1 underground coal mine.

Mechanical design considerations included operating capabilities, unimpeded travel road access and minimum belt curves. The design was dependent on the civil installation previously detailed by Orana Engineering. Often equipment is simply re-located from previous installations with minor modifications. Orana Engineering has developed unique methods for completing this type of design efficiently and at reduced cost to our clients.

AutoCAD was used to develop a mechanical design, from which a drawing set was produced that detailed out the mechanical aspects of the tripper installation

UG Conveyor Installations - MG Civil Installation

Engineers at Glencore’s Oaky No. 1 underground coal mine engaged Orana Engineering to determine civil work requirements to effectively utilise drive-head equipment in newly mined chambers for conveyor installations.

On completion of chamber mining, finished surfaces (rib and floor) may require modification for installation of the conveyor drive-head equipment. The civil design must determine concrete grades for drainage, safe access and reinforcing for conveyor equipment, while minimising trimming and concrete required.

Manipulating “as-cut” survey data using AutoCAD, Orana Engineering design staff could accurately determine where equipment might be installed with minimal trimming and concreting. A drawing set was produced detailing civil aspects of the conveyor design, including chamber trimming, equipment mounting locations, configuration of reinforcing and relative concrete levels.

Underground Workshop Concept Design

Due to expanding operations, Glencore's Oaky North underground operations saw benefit in having an underground workshop and refueling stations to reduce vehicle travel times and increase efficiencies. Orana Engineering was engaged to provide concept design and estimating assistance for project approval.

From communications with our client, Orana Engineering prepared concept general arrangement drawings for consideration. Based on these concept design drawings, a project capital estimate and project schedule were prepared for Oaky North.

From the information presented by Orana Engineering, the client could accurately consider whether the underground workshop was feasible and ensure that appropriate budgeting and project planning was completed at the concept design phase to improve confidence in the project prior to execution.

Water Polishing Plant Access Platform

BHP Billiton Cannington’s Port Storage Facility operates a water polishing plant for treatment of stored water. The system requires regular maintenance for replacement of plant filtration rods, however with maintenance ports inaccessible from the ground, work platforms had to be arranged. To simplify this task and improve safety, BHP Billiton Cannington identified the need for a permanent access platform.

Orana Engineering was engaged to design a platform that allowed easy access to the maintenance port, while ensuring access to existing services was not compromised.

Orana Engineering utilised AutoDesk Inventor to model a platform that would not impact on the existing structure, services or access routes while ensuring safety for maintenance workers. Following model verification, shop detail fabrication drawings were produced.

Yokogawa DCS Upgrade

Since 2005, Orana Engineering has provided 24/7 support for Glencore's Oaky Creek Coal control systems. At the CHPP a Yokogawa DCS installed in 1998 is used as the primary control system. With existing CentumCS Unix software no longer supported by Yokogawa, it was essential to complete an upgrade to the CentumCS3000 system.

Orana Engineering developed conversion tools to allow configuration data to be extracted from the CentumCS Unix platform and imported into the CentumCS3000 environment. These tools provided efficiency and accuracy for the conversion and delivered a significant cost saving.

The quality of conversion tools and simulation programs developed by Orana Engineering resulted in highly efficient site commissioning, completed without plant downtime.