Structural Engineering Consultants

Structural engineering deals with the design, construction, maintenance and assessment of permanent and temporary structures or structural systems. Structures are designed to work within their environment and accommodate relevant external forces such as wind, waves, earthquakes, etc. Structural engineers work closely with Orana Engineering’s other engineering disciplines such as mechanical and electrical to provide a complete design solution for our clients.

Orana Engineering can provide a range of structural engineering services including assessments and design of:

- Foundations;

- Access platforms;

- Services (e.g. pipework, cable ladder, etc) supporting structures;

- Monorails; and

- Structural inspections and audits.

We service coal, metalliferous, oil and gas clients as well as industrial and commercial clients. Explore the case studies below for more information on structural engineering services by Orana Engineering.

Orana Engineering Structural Engineering

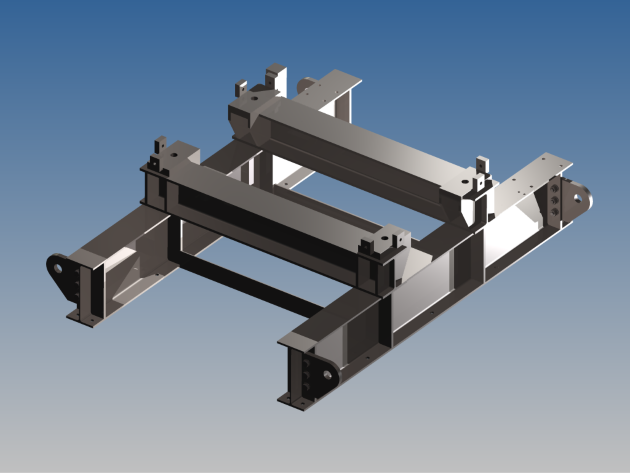

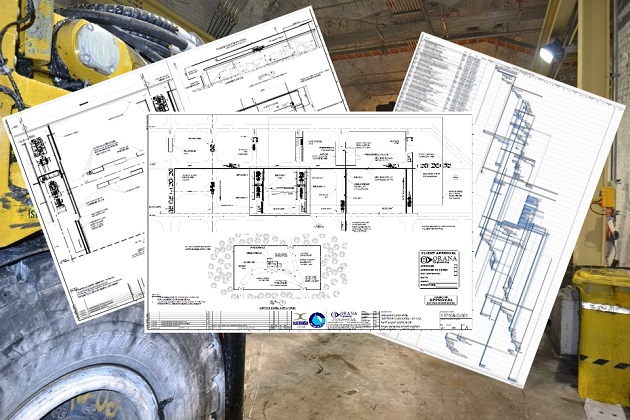

Mill Gear Box Frame

The IMT project team at MMG’s Century Zinc operations enlisted the assistance of Orana Engineering to produce a set of fabrication drawings for an existing gear box frame that required replacing. The frame had been in operation for some time, however there were no detailed drawings available for construction of a replacement unit. The design staff at Orana Engineering created a detailed 3D model using client-supplied photos and sketches, enabling designers to produce 2D fabrication drawings for approval. A review of the drawings was conducted by the client to confirm the layout and accurate alignment with the existing installation on site. Following minor adjustments, As-Built status drawings were reissued to the client, accurately capturing detail of the existing frame.

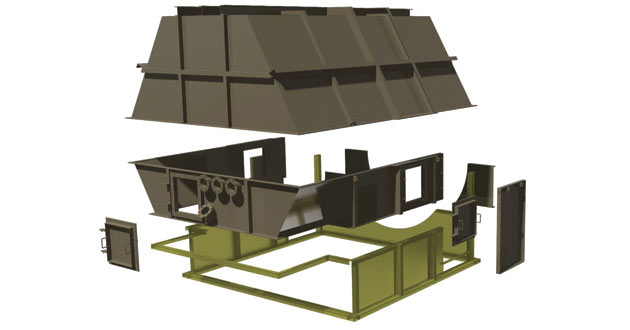

Read moreSAG Mill Cover

BHP Billiton Cannington Mine, is a significant miner and exporter of silver and lead concentrate. Orana Engineering was engaged to provide workshop fabrication drawings for a replacement cover to address corrosion issues around flanges and access openings on the existing SAG mill trommel sump cover. Following a site visit to obtain measurements, photos, drawings and documentation, the Orana Engineering design drafting team created a detailed 3D model of the existing structure incorporating new components to produce a set of detailed shop fabrication drawings while also revising multiple existing drawings. These drawings were reissued for construction after receiving client approval. The new cover sections and access panels improved the safety of trommel operation while also reducing inspection and maintenance time.

Read moreTank Farm Upgrade

Melbourne Bio Diesel’s James Cook University research facility required an elevated level area for installation of fresh sea water storage tanks. Orana Engineering was requested to design a solution that increased efficiency with tank drainage and improved safety around the tanks. A site visit was performed to gather measurements of the nominated tank farm area. This included identifying trees requiring removal and determining required tank heights and current ground levels. From the information gathered Orana Engineering used AutoCAD to model ground levels and the fill required to lift tanks to a suitable level for gravity drainage. The design incorporated a conical base on each tank for drainage and the introduction of buried control valves accessible via covered pits.

Read moreTank Static Line

Management at Carpentaria Gold’s Ravenswood Operation enlisted Orana Engineering to design a fall arrest system that could be easily removed and repositioned above multiple leach tanks, allowing for safe removal and servicing of tank agitators. From a site visit, Orana Engineering identified the need for an arrangement that could be easily disassembled and relocated to each leach tank. The design was challenging due to the varying nature of access structure members above tanks. Orana Engineering designers proposed an assembly utilising a common set of supporting columns with struts of varying lengths depending on the work location. A full set of shop fabrication and assembly drawings were issued with the final design providing safety for personnel working above open tanks.

Read moreTK102 Bypass Piping

When tasked with a major repair to one of their leaching tanks, personnel at Carpentaria Gold, Ravenswood enlisted the assistance of Orana Engineering to develop a solution that would allow process operations to continue whilst leaching tank TK102 was out of service. A site visit and discussions with the client suggested a bypass line be installed around TK102. By utilising site information, Orana Engineering designers were able to detail a new bypass line through the existing processing plant area. This involved minor modification of existing structural steel and addition of pipe supports for the new HDPE bypass pipeline. Bypass piping was successfully installed during normal operation with only tie-ins needing to be installed during a single shut down.

Read moreUnderground Workshop Concept Design

Due to expanding operations, Oaky North underground operations saw benefit in having an underground workshop and refuelling stations to reduce vehicle travel times and increase efficiencies. Orana Engineering was engaged to provide concept design and estimating assistance for project approval. From communications with our client, Orana Engineering prepared concept general arrangement drawings for consideration. Based on these concept design drawings, a project capital estimate and project schedule were prepared for Oaky North underground operations. From the information presented by Orana Engineering, Oaky North could accurately consider whether the underground workshop was feasible, and ensure that appropriate budgets and project planning was completed at the concept design phase to improve confidence in the project prior to execution.

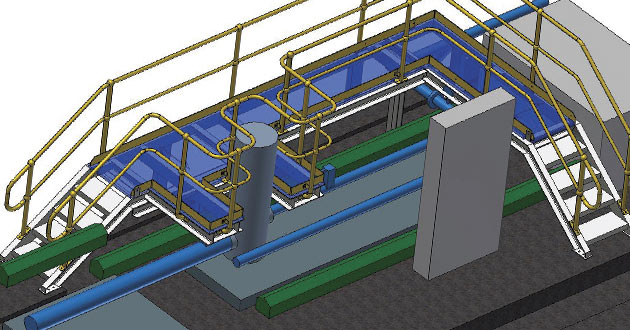

Read moreWater Polishing Plant Access Platform

BHPB Cannington’s Port Storage Facility operates a water polishing plant for treatment of stored water. The system requires regular maintenance for replacement of plant filtration rods, however with maintenance ports inaccessible from the ground, work platforms had to be arranged. To simplify this task and improve safety, BHPB Cannington identified the need for a permanent access platform. Orana Engineering was engaged to design a platform that allowed easy access to the maintenance port, while ensuring access to existing services was not compromised. Orana Engineering utilised AutoDesk Inventor to model a platform that would not impact on the existing structure, services or access routes while ensuring safety for maintenance workers. Following model verification, shop detail fabrication drawings were produced.

Read more