Engineering at Metalliferous Mines

For the metalliferous mining sector, North Queensland remains an ideal location for further mineral discoveries and is currently Australia’s largest producer of zinc, lead and silver. The region also ranks highly for copper, bauxite and gold. Other important minerals mined in Queensland are cobalt, nickel, phosphate rock, magnesite, magnetite, molybdenum, rhenium, scandium and tin. Minerals are extracted and recovered through underground and open cut mining operations and processed using onsite processing plants.

Orana Engineering has been engaged by a range of metalliferous mining clients throughout Queensland, with engineering experience in the mining, processing and storage of lead, silver, zinc, gold and copper. Our clients value our industry knowledge and experience, as well as our practical North Queensland location, allowing our team to be reactive and offer local, hands-on support. We understand the importance of compliance within the metalliferous industry, with our staff keeping up to date with all relevant legislation including the Mining and Quarrying Safety and Health Act and Regulations. Further information on the Act and Regulations can be found below.

Mining and Quarrying Safety and Health Act 1999

Mining and Quarrying Safety and Health Regulation 2017

We are well equipped to offer mechanical, electrical, structural and control systems engineering services for the metalliferous mining industry, assisting with engineering for fixed plant, processing plants, conveyor belts, concentrators and site infrastructure. Explore the case studies below to learn more about the value we have added for our metalliferous mining clients.

Orana Engineering Metalliferous Mine Engineering

Crusher Circuit Upgrade

Eloise Copper Mine purchased a Metso dual deck vibrating screen to replace an existing smaller screen and a second Omnicone cone crusher to provide a secondary crushing circuit for increased production and efficiency. Orana Engineering was engaged to develop a design solution and detailed drawings for the secondary crushing circuit which utilised as much existing equipment as possible.

Orana Engineering was able to provide an efficient, practical design solution while minimising the associated design costs to provide site personnel with information required to refurbish and install the conveyor equipment necessary for the crushing circuit.

Orana Engineering successfully completed the design within a tight project time frame and produced in excess of 100 detailed drawings.

Cable Failure Investigation

MMG’s Dugald River Mine in north-west Queensland had experienced issues with LV cables feeding large MCCs on site. Following damage to a cable, gland and gland plate within the Flotation Area MCC, Orana Engineering was engaged to conduct an investigation into the cause.

The faulted cable and two un-faulted cables from the same MCC incomer were transported to Orana Engineering’s Townsville office where they were inspected, dismantled, measured and photographed. A review of site data was carried out with conclusions indicating the most likely cause of failure was degradation of cable insulation due to heat generated at the cable gland by a circulating current in the armour of the single core cable.

Orana Engineering’s findings and methods for preventing similar occurrences were presented to the client in report format at the conclusion of the investigation.

PPP027 Plant Feed Upgrade

Century Mining’s zinc tailings treatment operation is situated in north-west Queensland and is the largest tailings retreatment operation in Australia. Century sought the services of Orana Engineering in providing engineering support for its PPP027 Plant Feed Upgrade Project.

The project scope encompassed multidisipline engineering design for the upgraded plant feed pumping system including Weir Warman pumps. The client also requested a mechanical engineering review into combined use of poly lined, rubber lined and UHMWPE piping supported by Orana Engineering’s liaison with product vendors. Electrical design and site based support was delivered by Orana Engineering to suit the requirement of the project resources and timeline. Civil and structural engineering design was completed for the underground services and concreted area and footings.

.webp)

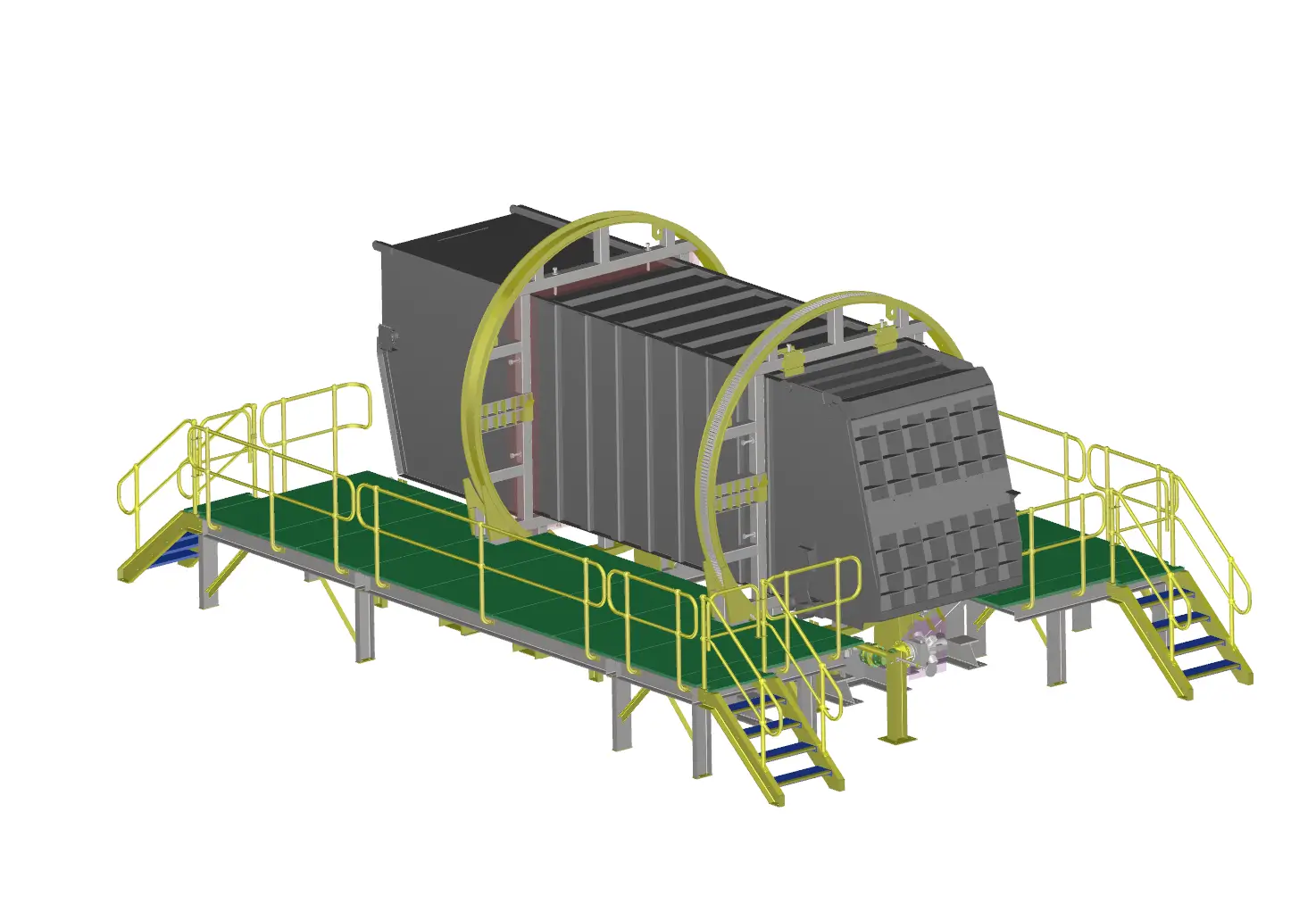

Skip Rotator

Glencore’s Ernest Henry Mine proposed to install a skip rotator to enable periodic maintenance and refurbishment of its underground ore hoist skips. The skip rotator was to consist of a removable access platform, a two-part skip cradle, plus a pneumatic drive motor and brake assembly supplied by the compressed air system. It was envisaged the rotator would enable ore skips to be rotated without the use of a 20T mobile crane and a 32T forklift which was the established method.

Orana Engineering was requested to provide mechanical and structural design and drawings of sufficient detail to allow fabrication, installation and operation of the skip rotator. In addition, Orana Engineering mechanical design personnel generated a model of the skip rotator using Autodesk Inventor which provided the client with a 3D overview of the design.

Structural Audits

Navarre Minerals engaged Orana Engineering to perform a structural audit of major assets within the processing plant at its Mount Carlton Gold Mine. The audit was limited to non-invasive, visual inspections of major assets and targeted obvious structural issues which would normally be identified as part of a condition inspection.

A desktop risk assessment was performed by Orana Engineering with documented results including a photo of each fault, relevant equipment details and location, observations, perceived fault severity and recommended remedial actions.

Findings from the audit were presented to Navarre within four categories ranging from ‘Monitor’ to ‘Minor’, ‘Major’ and ‘Severe’ with recommendations for follow-up via an onsite risk assessment and remedial actions as appropriate.

Underground Structural Audit

Orana Engineering was engaged by Glencore's Ernest Henry Copper Mine to complete a preliminary inspection and condition assessment according to AS13822 "Basis for Design of Structures - Assessment of Existing Structures". Outcomes from the audit were presented with a focus on facilitating optimal rectification and categorised in level of significance from high end catastrophic, through critical, high and medium, down to those items of low significance.

Orana Engineering added additional value to the client by identifying various non-conformances of access systems, general industry standards and safeguarding.

Tank Static Line

Management at Carpentaria Gold’s Ravenswood Operation enlisted Orana Engineering to design a fall arrest system that could be easily removed and repositioned above multiple leach tanks, allowing for safe removal and servicing of tank agitators.

From a site visit, Orana Engineering identified the need for an arrangement that could be easily disassembled and relocated to each leach tank. The design was challenging due to the varying nature of access structure members above tanks.

Orana Engineering designers proposed an assembly utilising a common set of supporting columns with struts of varying lengths depending on the work location. A full set of shop fabrication and assembly drawings were issued with the final design providing safety for personnel working above open tanks.

Gold Slurry Sampler

Orana Engineering was engaged to design new sampling equipment for improved sampling effectiveness at Carpentaria Gold’s Ravenswood operations.

A site visit was undertaken by Orana Engineering design staff to accurately record critical data. This enabled designers to produce a detailed 3D model which was used extensively during interactions with the client and ensured a fluent understanding of the project scope by both parties throughout the design process.

Orana Engineering was able to integrate new sampling equipment into the existing plant whilst minimising any impact on the operation. Various challenges were overcome with the result being successful delivery of drawings for fabrication and installation of equipment, allowing improved sampling and production reconciliation whilst minimising impact to operations.

TK102 Bypass Piping

When tasked with a major repair to one of their leaching tanks, personnel at Carpentaria Gold's Ravenswood Operations enlisted the assistance of Orana Engineering to develop a solution that would allow process operations to continue whilst leaching tank TK102 was out of service.

A site visit and discussions with the client suggested the installation of a bypass line around TK102. By utilising site information, Orana Engineering designerswere able to detail a new bypass line through the existing processing plant area. This involved minor modification of existing structural steel and addition of pipe supports for the new HDPE bypass pipeline.

Bypass piping was successfully installed during normal operation with only tie-ins needing to be installed during a single shut down.

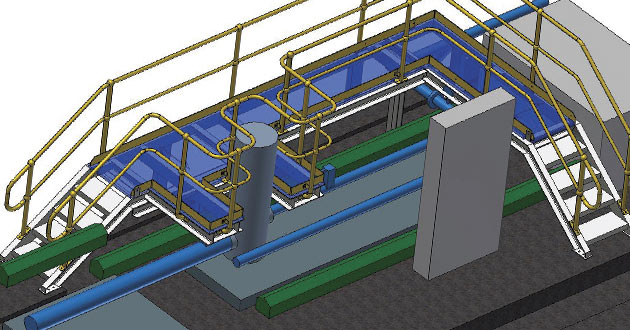

Water Polishing Plant Access Platform

BHP Billiton Cannington’s Port Storage Facility operates a water polishing plant for treatment of stored water. The system requires regular maintenance for replacement of plant filtration rods, however with maintenance ports inaccessible from the ground, work platforms had to be arranged. To simplify this task and improve safety, BHP Billiton Cannington identified the need for a permanent access platform.

Orana Engineering was engaged to design a platform that allowed easy access to the maintenance port, while ensuring access to existing services was not compromised.

Orana Engineering utilised AutoDesk Inventor to model a platform that would not impact on the existing structure, services or access routes while ensuring safety for maintenance workers. Following model verification, shop detail fabrication drawings were produced.