Drawing Revisions

Over the life of an operation, many of a site's drawings will require revision which can be due to plant modifications or simply a drawing being updated with as-built information. Maintaining up to date drawing revisions reflecting this information is integral to a site providing a safe, practical and efficient workplace.

When a client makes changes during the design, construction and installation phases of a project (e.g. producing as-built plans), or when modifications are made to existing plant a drawing revision is required. Clients provide red pen or hand drawn mark-ups which our experienced design draftspeople interpret and document, resulting in accurate electronic drawing revisions. Clients receive a well presented and accurate reflection of their mark-ups in PDF and CAD format (or other native format as required). The revision of drawings is about keeping drawing records up to date to accurately show the details of a plant's existing construction or to define the scope of what is to be installed or modified for a project. In turn this enables accurate information for all to access, with the potential to prevent safety hazards or delays associated with misinformation.

Continually managing drawing revisions can create cost savings and time efficiencies, which are often realised during the life of the operation (maintenance and operations) or the next project, when accurate records allow all parties to start with the right information and same understandings. Maintaining accurate drawing revisions is also a legislative requirement for some industries, particularly the coal industry or when dealing with electrical drawings.

Maintaining accurate drawing revisions

- Protects the safety of those operating or modifying the plant in the future by ensuring they are working with the correct information, and preventing the risk of misinformation causing injury, particularly around electrical work;

- Keeps the end user in mind - allowing maintenance and operational personnel easy and confident access to the correct information, ensuring processes can run smoothly. It is easier for personnel to make onsite decisions when the correct information is available;

- Encourages all team members to have confidence in all site drawings, encouraging new revisions to be updated as required, perpetuating a culture of accuracy and safety within the team. If issues arise, staff can have confidence in the information available as they know drawing revisions are a priority within the team and can be relied upon; and

- Cost and time savings for future modifications, making the process easier by ensuring accurate drawings are available as a starting point for future plans and modifications. Incorporated with a good drawing management system, client’s personnel can be confident that they are working with the most current and up to date revision.

Outsourcing drawing revision services to Orana Engineering means that our clients do not have to dedicate time or resources to this service, including resourcing suitable discipline specific personnel or the overheads for maintaining software updates. Clients can have confidence that Orana Engineering will do it once and do it right, taking into consideration the effect that any revisions may have in the bigger picture, through our drawing management systems identifying any additional drawings that may also need to undergo revision. Our ability to call upon qualified and discipline specific personnel with trade backgrounds ensures accurate interpretation of client’s markups. Our staff understand that drawings are more than lines on paper, that they reflect something real onsite and have real implications for those relying on the drawings.

Our rigorous Quality Assurance systems ensure that drawings are efficiently revised with the highest level of accuracy. The thorough drawing revision service includes designing, checking, engineer calculations (where applicable), CAD drafting and back drafting checks, engineering design drafting, reviews and drawing registration. If required by our clients, our in-house engineering expertise also allows for clients to benefit from qualified engineering checks on their revisions.

Orana Engineering has the resources and capabilities to provide our clients with a complete engineering and design solution that is inclusive of performing engineering design drawing revisions, as-built revision and importantly maintaining the register of the sites drawing management system.

Contact Orana Engineering for further information about our drawing revision services and how they complement our drawing management systems and design drafting services. Or for more information about the services Orana Engineering can provide, please review our Capability Statement.

Orana Engineering Drawing Revisions

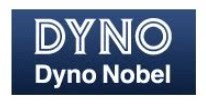

Redraw Electrical Drawings

To ensure plant maintainability and personnel safety, Dyno Nobel employed Orana Engineering to redraw its low voltage and high voltage single line diagrams, while also confirming their accuracy and functionality.

Through the use of client photos, documentation and discussions Orana Engineering was able to accurately redraw 52 low voltage single line diagrams as well as 6 high voltage single line diagrams.

During the redraw process Orana Engineering identified that a larger size drawing template was required to ensure critical information was easily readable on a single drawing. An A0 size drawing template was designed to meet Dyno Nobel's drawing standards with the template providing links for the document management system to easily access drawing metadata.

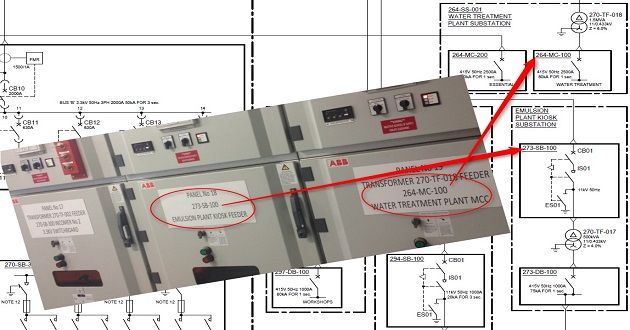

SAG Mill Cover

BHP Billiton Cannington Mine, is a significant miner and exporter of silver and lead concentrate. Orana Engineering was engaged to provide workshop fabrication drawings for a replacement cover to address corrosion issues around flanges and access openings on the existing SAG mill trommel sump cover.

Following a site visit to obtain measurements, photos, drawings and documentation, the Orana Engineering design drafting team created a detailed 3D model of the existing structure incorporating new components to produce a set of detailed shop fabrication drawings, while also revising multiple existing drawings. These drawings were reissued for construction after receiving client approval.

The new cover sections and access panels improved the safety of trommel operation while also reducing inspection and maintenance time.

Sewage Treatment Plant Refurbishment

To increase productivity and maintain compliance with legislative standards, Glencore Oaky Creek Coal employed the services of Orana Engineering to design and manage the electrical aspects of an upgrade to their existing sewage treatment plant.

The project was managed on-site by others, with Orana Engineering providing electrical engineering, design, project management and construction / commissioning assistance.

Upon completion of installation, Orana Engineering updated all drawings to reflect any changes made, thus providing Glencore Coal with as-built drawings which will make any future maintenance or fault-finding work more efficient and cost effective, as well as providing legislative compliance.

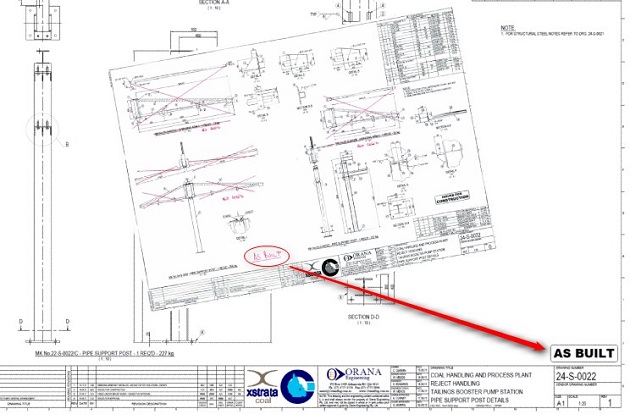

Tailings Pumping System - As-Built

At the completion of tailings pumping upgrades of the main CHPP and Module 4 CHPP at Oaky Creek Coal, Orana Engineering received as built drawings from site and was requested to make electronic revisions for upload into the client’s Drawing Management System.

Over 80 drawings had received red pen site mark-ups indicating either that the design had been constructed as per the drawings, or highlighting design changes made during the construction phase of the project. Orana Engineering reviewed these mark-ups and formally revised all drawings to as built status, incorporating the site mark-ups.

The final set of drawings was uploaded to the client’s Drawing Management System ensuring site personnel had access to the latest as built drawings.

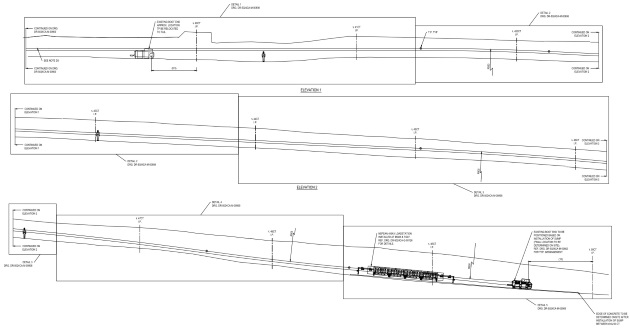

TC04 Trunk Conveyor Extensions

Carborough Downs Coal Mine is an underground operation utilising conveyors to transport raw material to the surface for processing. As operations progress new trunk conveyor extensions are required.

Orana Engineering was engaged to assist with the process of extending an underground trunk conveyor. This involved using survey data of the conveyor heading and designing a suitable belt profile, utilising minimum conveyor curves identified in the conveyor power and tension analysis.

Orana Engineering produced a set of drawings detailing the belt profile, conveyor structures and locations for roof bolts that the structures would be suspended from. These drawings enabled site engineers to complete the conveyor structure installation and conveyor extension with minimal risk of error and conveyor tracking problems.