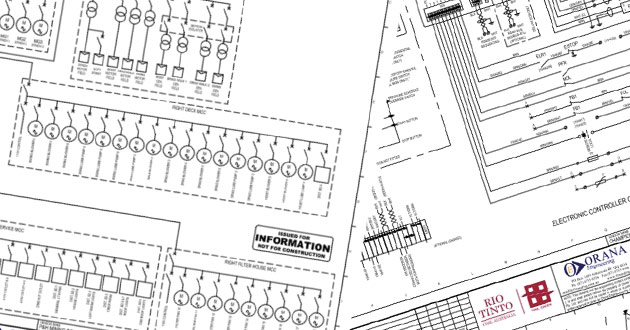

Drawing Revisions

Over the life of an operation, many of a site's drawings will require revision which can be due to plant modifications or simply a drawing being updated with as-built information. Maintaining up to date drawing revisions reflecting this information is integral to a site providing a safe, practical and efficient workplace.

When a client makes changes during the design, construction and installation phases of a project (e.g. producing as-built plans), or when modifications are made to existing plant a drawing revision is required. Clients provide red pen or hand drawn mark-ups which our experienced design draftspeople interpret and document, resulting in accurate electronic drawing revisions. Clients receive a well presented and accurate reflection of their mark-ups in PDF and CAD format (or other native format as required). The revision of drawings is about keeping drawing records up to date to accurately show the details of a plant's existing construction or to define the scope of what is to be installed or modified for a project. In turn this enables accurate information for all to access, with the potential to prevent safety hazards or delays associated with misinformation.

Continually managing drawing revisions can create cost savings and time efficiencies, which are often realised during the life of the operation (maintenance and operations) or the next project, when accurate records allow all parties to start with the right information and same understandings. Maintaining accurate drawing revisions is also a legislative requirement for some industries, particularly the coal industry or when dealing with electrical drawings.

Maintaining accurate drawing revisions

- Protects the safety of those operating or modifying the plant in the future by ensuring they are working with the correct information, and preventing the risk of misinformation causing injury, particularly around electrical work;

- Keeps the end user in mind - allowing maintenance and operational personnel easy and confident access to the correct information, ensuring processes can run smoothly. It is easier for personnel to make onsite decisions when the correct information is available;

- Encourages all team members to have confidence in all site drawings, encouraging new revisions to be updated as required, perpetuating a culture of accuracy and safety within the team. If issues arise, staff can have confidence in the information available as they know drawing revisions are a priority within the team and can be relied upon; and

- Cost and time savings for future modifications, making the process easier by ensuring accurate drawings are available as a starting point for future plans and modifications. Incorporated with a good drawing management system, client’s personnel can be confident that they are working with the most current and up to date revision.

Outsourcing drawing revision services to Orana Engineering means that our clients do not have to dedicate time or resources to this service, including resourcing suitable discipline specific personnel or the overheads for maintaining software updates. Clients can have confidence that Orana Engineering will do it once and do it right, taking into consideration the effect that any revisions may have in the bigger picture, through our drawing management systems identifying any additional drawings that may also need to undergo revision. Our ability to call upon qualified and discipline specific personnel with trade backgrounds ensures accurate interpretation of client’s markups. Our staff understand that drawings are more than lines on paper, that they reflect something real onsite and have real implications for those relying on the drawings.

Our rigorous Quality Assurance systems ensure that drawings are efficiently revised with the highest level of accuracy. The thorough drawing revision service includes designing, checking, engineer calculations (where applicable), CAD drafting and back drafting checks, engineering design drafting, reviews and drawing registration. If required by our clients, our in-house engineering expertise also allows for clients to benefit from qualified engineering checks on their revisions.

Orana Engineering has the resources and capabilities to provide our clients with a complete engineering and design solution that is inclusive of performing engineering design drawing revisions, as-built revision and importantly maintaining the register of the sites drawing management system.

Contact Orana Engineering for further information about our drawing revision services and how they complement our drawing management systems and design drafting services. Or for more information about the services Orana Engineering can provide, please review our Capability Statement.

Orana Engineering Drawing Revisions

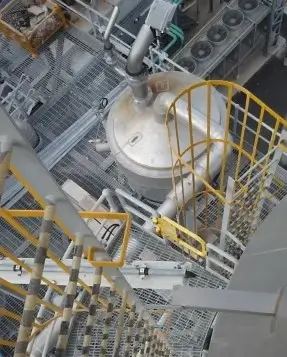

Brine Concentrator Stair Tower Rescue Lift Points

Veolia Water’s Kenya Water Treatment Plant contacted Orana Engineering to provide engineering and design drafting assistance in relation to installation of fall-arrest rescue anchor points to the brine concentrator stair tower.

Orana Engineering mechanical personnel undertook a review of applicable codes and standards in order to identify key safety considerations in the use of fall arrest systems. Calculations were performed on existing structural members locally to determine beam capacity for the addition of lugs at 6 points as identified by the client.

Deliverables for the project included an RPEQ supervised design for manufacture and installation of the lugs, revision of existing client drawings to reflect design changes and creation of a new drawing including both general and detailed information for new lug locations.

Orana 4 Pump Station

Veolia Water engaged Orana Engineering to look into options for a replacement pump station at its QGC Kenya Central Water Treatment Facility.

High level concept design investigations were initiated for options to replace the existing diesel driven manually controlled pump system for transferring brine from the site's Orana 4 Pond to the plant for treatment. Both a land based primed pump station and a water based floating pump station were given high level consideration. A detailed concept options report was developed for review and consideration by site stakeholders.

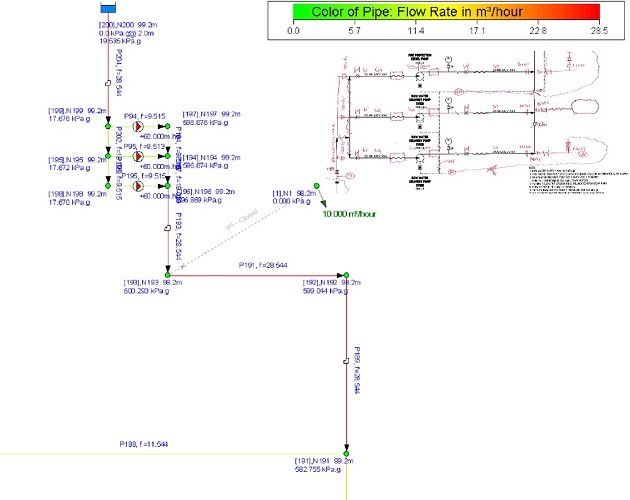

CHPP Projects - Water Balance

Orana Engineering was requested by the CHPP Manager Capital Projects at Glencore’s Collinsville coal mine to provide engineering and scoping assistance with respect to the mine’s underground water service repair and upgrade scope of work.

A member of the Orana Engineering mechanical engineering team attended site to liaise with onsite stakeholders, operators, plumbers and surveyors and to gather information on raw water and potable / fire water supply issues being experienced.

Upon return from site, a high-level engineering review was conducted along with detailing of raw water and potable / fire water scopes. Basic hydraulic modelling was also carried out to identify pressure spike issues and water hammer. Following review completion, the client was provided with a basis of design and a summary of Orana Engineering’s findings and recommendations.

Compressed Air Upgrade

Anglo American’s Moranbah North CHPP operations personnel contacted Orana Engineering to investigate problems with low compressed air pressures and air flow rates. There were additional concerns regarding compressor reliability associated with the operation of equipment, valves, tooling, maintenance and instrumentation.

Orana Engineering conducted an onsite investigation which included preparing as-built drawings of the high-level compressed air distribution network within the CHPP. A review of historic transmitter data for the system was also carried out to identify issues and bottlenecks. System performance was also reviewed against site-checked pressures and engineering flow rate and pressure loss.

Upon conclusion of the investigation a summary of findings and recommendations was presented to the client encompassing as-built drawings, calculations, a summary of works and recommendations for resolution.

Inner Bypass Valves

Orana Engineering was engaged by MMG's Century Mine to design an upgrade within the concentrator for increased flow from a flotation cell to a tailings trough.

Orana Engineering conducted a concept investigation of available options to increase the flow rate. Results were presented for a range of design and operating conditions, and a preferred option was selected for detailed design.

Orana Engineering design staff created a 3D model of the new pipeline using Autodesk Inventor. The 3D model was used to produce fabrication drawings for pipe supports, new platform and new pipe bridge. Drawings also included isometric pipe spool drawings and revised P&ID drawings.

MIA Services Audit

Orana Engineering was requested to complete an audit of water and wastewater services at BMA’s Blackwater Mine. The audit was to determine whether new go-line infrastructure would adversely impact the existing mine industrial area services, and whether additional infrastructure or upgrades were required.

Data collected from site by Orana Engineering was used to prepare a hydraulic model for each service. Modelling results, findings and recommendations were included in a detailed report outlining the capacity and utilisation of existing services to quantify available system capacity for the proposed new buildings. Additionally, Orana Engineering’s drawing revision services were utilised to formally revise site P&IDs to As Built, incorporating mark-ups made during the site visit.

MIBC & Diesel Upgrade

The purpose of the Reagent System Upgrade at Oaky Creek was installation of new reagent storage tanks, discharge / delivery pumping systems and automated flow control distribution manifolds for the delivery of each reagent to the nominated process connections.

Orana Engineering performed mechanical, electrical and control systems design, drafting and engineering for the project. The primary deliverables included scope of works, construction drawings, functional specification, BOM, spares lists and equipment / instrument data sheets.

Orana Engineering managed the onsite commissioning of the system and provided a system handover to operations for implementation. An Operation & Maintenance Manual and Hazardous Area Dossier were provided on project completion.

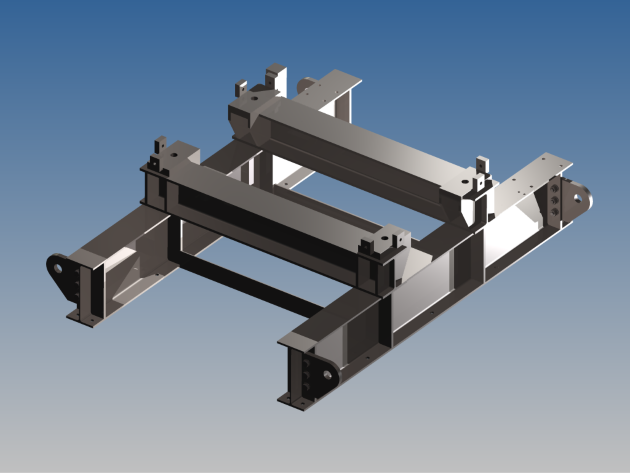

Mill Gear Box Frame

The IMT project team at MMG’s Century Zinc operations enlisted the assistance of Orana Engineering to produce a set of fabrication drawings for an existing gear box frame that required replacing. The frame had been in operation for some time, however there were no detailed drawings available for construction of a replacement unit.

The design staff at Orana Engineering created a detailed 3D model using client-supplied photos and sketches, enabling designers to produce 2D fabrication drawings for approval. A review of the drawings was conducted by the client to confirm the layout and accurate alignment with the existing installation on site. Following minor adjustments, As-Built status drawings were reissued to the client, accurately capturing detail of the existing frame.

Onsite Accommodation Camp Services

Orana Engineering was engaged by Oaky Creek Coal to assist in design and construction of onsite camp accommodation, including an HV substation for power and potable water supply.

The brief included mechanical, electrical and control systems design, drafting and engineering for the project. Deliverables included scope of works, construction drawings, functional specification, drawing and equipment registers, commissioning and operating spares lists and equipment and instrument data sheets.

Orana Engineering provided PLC configuration and commissioning assistance for pump control, acted as Client Representative during construction, managed onsite commissioning of the system, and provided a handover to operations for implementation.

Operation & Maintenance Manuals for potable water storage and the HV substation were provided upon completion.

Redraw Dragline DL007 Drawings

To improve the maintainability of plant electrical systems and personnel safety, Hail Creek Mine employed the drawing revision services of Orana Engineering to redraw electrical power, control and termination diagrams associated with its Dragline 7 into AutoCAD format.

Having electrical drawings in CAD (computer aided design) format, is one of the most efficient ways to capture site electrical modifications, installations or as-building changes for ready access by site personnel involved in maintenance and operations.

Working closely with site contacts and onsite electricians, Orana Engineering was able to accurately reproduce 247 electrical drawings into AutoCAD for Dragline 7.