Design Drafting

Design drafting is the process of graphically communicating the works that are to be performed for a project. When well executed, design drafting is cost effective and increases the likelihood of project solutions being delivered that are safe, easily maintainable, on schedule, on budget and consistently meet or exceed the original requirements. Design drafting provides an opportunity to visualise the proposed project outcome and ensures that all involved on a project are working towards common goals with sufficient detail.

Like all effective communications, accuracy, relevance and presentation are essential. Design drafting must cater to the entire audience who will use and depend on the drawings, before, during and after the project. Design drafted drawings are relied upon from the concept and construction stage of a project, right through to ongoing maintenance and operations requirements, and form the basis for future modifications and growth. From well design drafted drawings, the ongoing process of drawing management and drawing revisions is greatly simplified. For our clients this means the benefit of accessible, accurate and timely information on an ongoing basis.

Orana Engineering’s unique and customised approach to design drafting strives to ensure that:

- All aspects of a project’s implementation are fully considered to avoid unforeseen surprises;

- Personnel of all engineering disciplines and professions involved in the project (client, project management, design, construction and maintenance) are fully informed and have given thorough consideration to the design and what is required of them to achieve it; and

- Critical to brownfield operations, that there is no potential for drawings proposing a project’s scope to be confused with drawings of what is actually installed, avoiding an unsafe situation where site maintenance personnel could be working with an incorrect revision of a drawing.

Our projects are delivered to meet the HSEC, quality assurance, cost and schedule targets originally set. Considering this, good design drafting does not necessarily reduce the cost of a project, rather it strives to increase cost efficiencies by preventing project cost and schedule blowouts, which can ultimately impact safety and quality. What design drafting really targets is eliminating the negative impacts that insufficient or poor design drafting can have on the cost, quality and schedule of a project as well as the safety of those relying on the accuracy of drawings. Onsite design modifications during or after construction are far more costly and time consuming to resolve as opposed to modifications when they are identified offsite or before procurement of incorrect equipment.

The key to delivering high quality and valued design drafting services lies within our in-house resources, expertise and focus on quality. Internal quality assurance systems at Orana Engineering are first rate and at the core of the design drafting we produce. Our best practice approach means that our learnings are continuously incorporated into our work to benefit all clients. We are experienced working with a wide range of tools for design drafting, such as AutoCAD, Inventor and other Autodesk products.

Our multi-discipline design drafting services include:

- Electrical;

- Mechanical and Pipework;

- Civil / Structural;

- Control Systems (P&ID’s); and

- Animations and walk-through.

While design drafting can be offered as a stand-alone service which is inclusive of the necessary engineering certifications, our clients can benefit from Orana Engineering’s portfolio of other drafting related services such as drawing management and drawing revision while also taking advantage of other services provided by Orana Engineering including engineering services, project management and Client Engineer.

Contact us for further information regarding the design drafting services provided by Orana Engineering or to obtain a quote for design drafting assistance that you require. Review our capabilities for other details you may require.

Orana Engineering Design Drafting

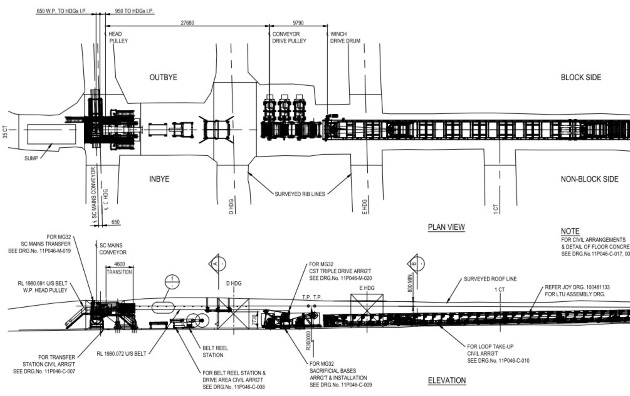

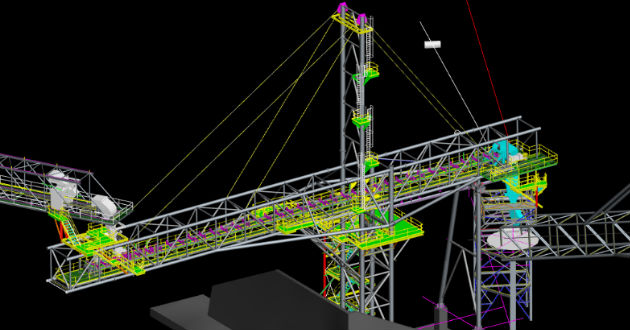

UG Conveyor Installations - MG Mechanical Installation

Detailing the installation of mechanical equipment and conveyor structures is one of the final steps for completing a maingate drive-head design. Installations designed by Orana Engineering for Glencore’s Oaky No.1 underground coal mine included detailing drive arrangements, transfer stations, take-up units, maintenance equipment and the overhead structures supporting the carry belt. Mechanical design must consider a number of factors, including meeting the required operating capabilities, allowing for unimpeded access along travel roads, and maintaining minimum belt curves. Often equipment is relocated from previous installations with minor modifications in transfer angle and number of drives. Orana Engineering has developed unique methods for completing this type of design, enabling us to keep total costs down for our clients.

Read moreCombabula Bore Pump

Prime Pump Company was contracted by Origin Energy and Laing O’Rourke to supply an upgraded bore pumping system at Origin’s Combabula site. RIE Services was contracted by Prime Pump Company to supply and install electrical components for the upgrade, with Orana Engineering subsequently engaged by RIE Services to complete a fault protection study on the new installation. Using SKM Power Tools for Windows software and manual calculation techniques for verification, together with information from RIE and Prime Pump Company, Orana Engineering produced an HV/LV model calculating fault levels and completing a protection co-ordination study. From the study it was recommended a new circuit breaker be introduced to protect the transformer, variable speed drive and supply cables.

Read more10M TAGS Sled

At James Cook University, MBD Energy operates a research facility investigating methods of cultivating and harvesting algae. To facilitate greater control of the algae agitation sleds, Orana Engineering was engaged to design and commission mechanical, electrical and control systems that would enable agitation sled velocity and frequency of travel to be automated. The system was designed and implemented by Orana Engineering utilising Allen Bradley Powerflex VVVF drives and a Controllogix’s PLC with an RSView SCADA interface. Orana Engineering was able to help MBD Energy improve the efficiency and quality of their research results by providing technical knowledge and assistance through our control systems, electrical engineering and mechanical engineering services.

Read more22M Flyover Conveyor

Oaky Creek Coal engaged Orana Engineering to perform electrical and control system design aspects of a 22M Flyover Conveyor to provide an interface between two existing conveyor systems. Orana Engineering’s brownfield engineering expertise was drawn upon to resolve complexities in interfacing two different coal streams, powered from separate substations and controlled from independent process control systems. Should one system need to be shutdown it was necessary that the other system was not impacted. The electrical engineering scope included powering the conveyor and transfer systems and providing lighting designs and power distribution. Control system engineering included selection and specification of instrumentation, specification of control system hardware and development of a functional specification.

Read moreBall Mill No. 2 Recommissioning

FMR Investment's Eloise Copper Mine had a requirement to recommission their No.2 Ball Mill. During the process of the recommissioning works it was identified that a means to relocate the grinding media to the feed chute needed to be designed and engineered with RPEQ certification.

Read moreCrane Lifting Beam

The mother beam of the 40T ship loading crane at the Port of Townsville was nearing the end of its 30 year service life. Xstrata Copper engaged Orana Engineering to redesign the beam based on the existing beam and to incorporate changes in compliance with latest regulations. After fully modelling the mother beam using Autodesk Inventor, RPEQ approved shop detail drawings were produced. Electrical monitoring systems were introduced to enable crane operators to confirm when the mother beam was fully engaged with various attachments and control wiring to the beam was redesigned to include two cable drums whereas the original had three. Mechanical redesign included a failsafe back-up locking system and design improvements highlighted by feedback from maintenance personnel.

Read moreCrusher Circuit Upgrade

Eloise Copper Mine purchased a Metso dual deck vibrating screen to replace an existing smaller screen and a second Omnicone cone crusher to provide a secondary crushing circuit for increased production and efficiency. Orana Engineering was engaged to develop a design solution and detailed drawings for the secondary crushing circuit which utilised as much existing equipment as possible. Orana Engineering was able to provide an efficient, practical design solution while minimising the associated design costs to provide site personnel with information required to refurbish and install the conveyor equipment necessary for the crushing circuit. Orana Engineering successfully completed the design within a tight project time frame and produced in excess of 100 detailed drawings.

Read moreCyanide Tank Upgrade

Carpentaria Gold identified that bunding around their Ravenswood cyanide storage tank was inadequate. Sodium Cyanide, used in the gold recovery process, is potentially lethal to humans and animals and detrimental to the environment. It is necessary to ensure it can be safely contained in an emergency. Orana Engineering provided an innovative solution comprising a smaller tank fitted inside the existing tank. The design minimised loss of storage capacity by providing a smaller tank for primary storage whilst maintaining the existing external tank to act as the bund. Utilising the existing tank as a bund, Orana Engineering delivered a design that met the client brief while re-using the majority of major tie-in points and providing improved access for maintenance.

Read moreFB-028 Tank Lifting Beam

During an upgrade to the Concentrator at MMG’s Century Mine located in Western Queensland, Orana Engineering was engaged to design a lifting beam for the installation of a new flotation cell.

Read moreFlotation Cell Upgrade

To increase the efficiency of their concentrator, Eloise Copper Mine enlisted Orana Engineering to provide engineering and design assistance with installation of three copper concentrate scavenger cells within the existing plant. 3D models created by Orana Engineering designers were used to visually communicate solutions for new and existing equipment locations and structure arrangements. Detailing of these concept models enabled Orana Engineering to identify key tie-in locations within the plant for survey during the detailed design phase. A multidisciplinary approach during detailed design ensured improved efficiency, with brownfield engineering challenges in relocating / connecting to existing equipment successfully achieved. Upon design completion the client was provided with an installation drawing set and scope of work.

Read more