Project Management

At Orana Engineering, project management is about delivering high quality outcomes for our clients. Our experienced Project Managers co-ordinate all aspects of a project to ensure the client’s targets are consistently achieved. Managing the core elements of cost, quality and schedule, successful project management realises the right balance and manages conflicts between each one.

Also of great importance for successful project management is the understanding of the client’s needs and expectations. Orana Engineering’s Project Managers have a unique skillset to draw upon with their combination of site experience, practical backgrounds and engineering qualifications allowing them to truly understand our clients' needs and expectations and create outcomes that align with this, meeting all key HSEC, quality assurance, cost and schedule targets throughout the process.

In the role of Project Manager, Orana Engineering has the experience and resources to:

- Co-ordinate various work groups and organisations;

- Schedule and co-ordinate regular meetings;

- Manage project variations;

- Promote and enforce client HSEC requirements;

- Prepare and track project schedules;

- Communicate project matters to all relevant parties;

- Schedule permits and outages;

- Prepare project reports; and

- Track budgets, budget forecasting and cost control.

Engaging our project management services ensures that all aspects which effect the delivery of a project are the responsibility of our Project Managers, including resolving commercial issues, tendering and liaising with subcontractors, risk management and HSEC issues, commissioning and handover. Personnel have access to a wide range of tools, procedures and processes that have been developed and refined by Orana Engineering to ensure effective cost estimation, management of budgets and change management.

Our project management services are of value throughout all stages of a project, from concept design through to detailed design, construction and handover. An experienced Orana Engineering Project Manager adds value to a project by:

- Dedicating a resource to manage the project, freeing up the time of the client so they can focus on the day to day operational issues;

- Allowing clients to remain informed and be in control of the project without having to dedicate time to managing the details;

- Providing the potential to achieve the highest quality outcome by engaging a practical Project Manager that has the time, expertise and experience to do the job right. Orana Engineering’s Project Managers are skilled engineers with hands on site experience;

- Seamlessly integrating additional services as required such as Client Engineer, design drafting, drawing revisions and drawing management giving clients one point of contact for any mechanical, electrical, structural or control systems engineering services requirements; and

- Offering the confidence of an experienced project management service with a proven track record.

An added advantage of being a smaller organisation is that for larger projects (i.e. >$2.5M), we can act on behalf of the client in the role of Project Manager and/or Client Engineer without a conflict of interest, as Orana Engineering do not tend to pursue design works for larger engineering projects.

Orana Engineering has a proven track record ensuring outcomes are consistently achieved and has project managed projects with values in excess of $20M. Our reliable Project Managers are technical experts and bring a depth of knowledge and experience to every project.

Contact Orana Engineering for further information about our project management services or to request a no obligation proposal. Our Capability Statement is also available for download providing more information about the services Orana Engineer offers.

Orana Engineering Project Management

TK102 Bypass Piping

When tasked with a major repair to one of their leaching tanks, operations staff at Carpentaria Gold’s Ravenswood Operations enlisted the assistance of Orana Engineering to develop a solution that would allow for process operations to continue whilst leaching tank TK102 was out of service.

Read moreUG Conveyor Installations – MG32 Tripper Chamber

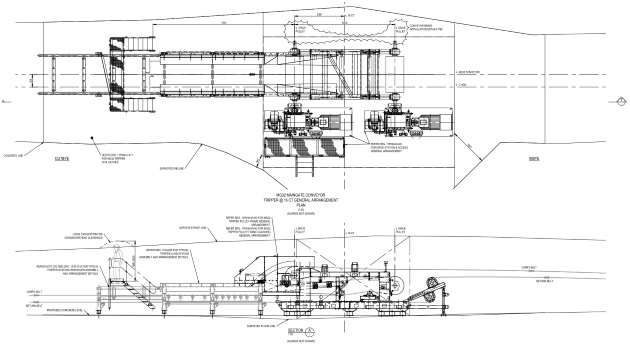

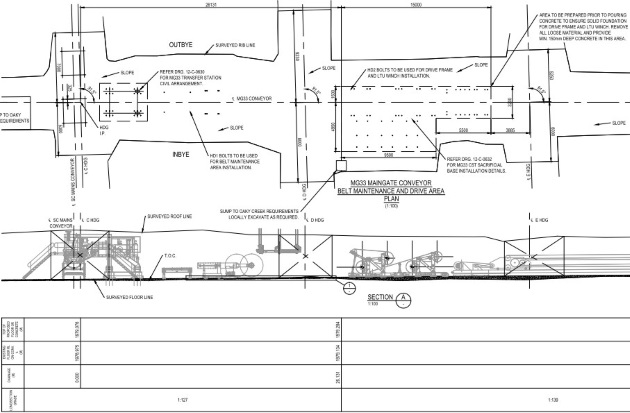

Maingate roadways mined to accommodate longwall conveyors at Glencore’s Oaky No. 1 underground coal mine can vary from a few hundred meters to over 4 kilometres in length. Transporting vast quantities of coal over long distances requires a significant amount of power. In some cases the drive-head power is insufficient or is constrained by the allowable belt tension and an additional drive / power source is required to meet the required operating capacity. Commonly this additional power will come in the form of a driven conveyor tripper installed at a nominal point along the conveyor, which requires the appropriate excavation for the tripper installation inclusive of drives, tripper frame, braking and belt starter.

Read moreUG Conveyor Installations – MG32 Tripper Civil Design

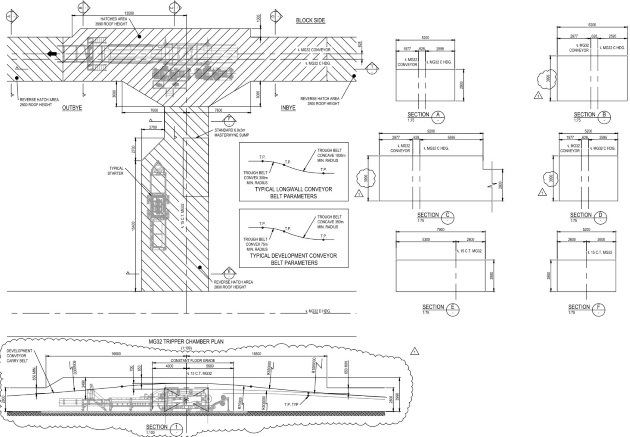

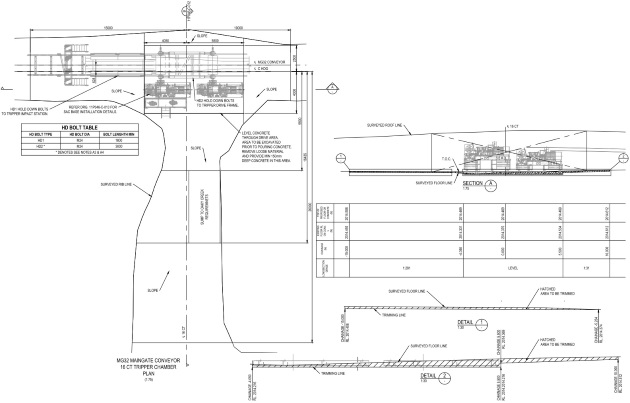

The site engineers at Glencore’s Oaky No. 1 underground coal mine have engaged Orana Engineering to determine the extent of the civil work required to install the maingate tripper equipment in MG32 longwall conveyor.

Read moreUG Conveyor Installations – MG32 Tripper Mechanical Design

In high capacity longwall conveyor arrangements, the installation of a tripper will typical occur after the chamber has been fully developed. The installation designed by Orana Engineering for MG32 conveyor for Glencore’s Oaky No.1 underground coal mine detailed the arrangement of the tripper drives, brakes, pulley frame and load station.

Read moreUG Conveyor Installations - MG Chamber Design

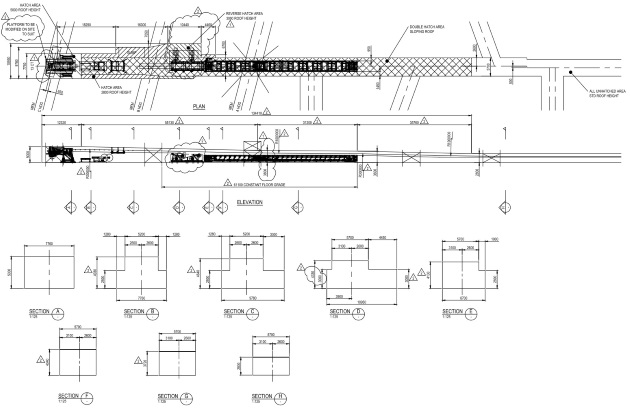

Mining and transporting millions of tonnes of raw material every year requires significant infrastructure and planning for future works. The site engineers at Glencore’s Oaky No. 1 underground coal mine have engaged Orana Engineering on multiple occasions (MG33C and MG34) to design new conveyor drivehead excavations (chambers) to install conveyor drivehead equipment for development and longwall coal mining.

Read moreUG Conveyor Installations - MG Civil Installation

The site engineers at Glencore’s Oaky No. 1 underground coal mine have requested the assistance of Orana Engineering to determine the extent of the civil work required to effectively utilise the drive-head equipment in newly mined chambers for conveyor installations for MG32, 33, 33C, 34, 35 and 36.

Read moreUnderground Workshop Concept Design

Due to expanding operations, Oaky North underground operations saw benefit in having an underground workshop and refuelling stations to reduce vehicle travel times and increase efficiencies. Orana Engineering was engaged to provide concept design and estimating assistance for project approval. From communications with our client, Orana Engineering prepared concept general arrangement drawings for consideration. Based on these concept design drawings, a project capital estimate and project schedule were prepared for Oaky North underground operations. From the information presented by Orana Engineering, Oaky North could accurately consider whether the underground workshop was feasible, and ensure that appropriate budgets and project planning was completed at the concept design phase to improve confidence in the project prior to execution.

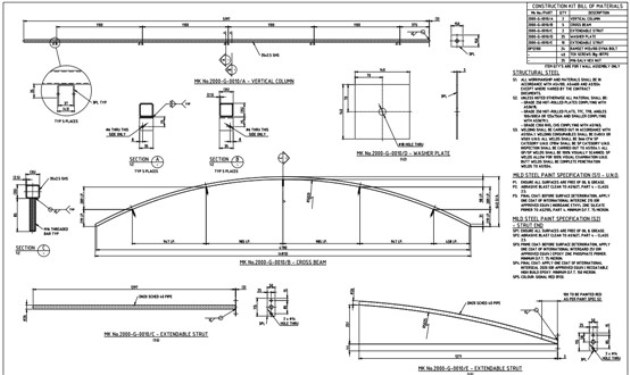

Read moreWall Kit Drafting

BHP Billiton Cannington Mine is a significant underground Silver and Lead mining operation located in Western Queensland. Following completion of the ore extraction from each stope, paste backfill is used to fill the open void, which stabilises the area and allows for mining of adjacent stopes. This is achieved by constructing a fill wall across roadways, which provides a stable wall for areas that are being back filled, eliminates intrusion from back filled areas, and allows the back filling to achieve a higher density.

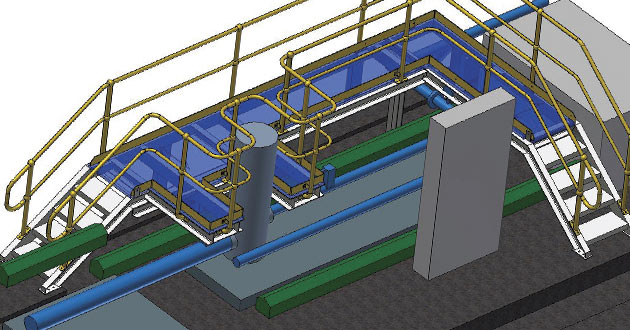

Read moreWater Polishing Plant Access Platform

The BHPB Cannington Port Storage Facility located at the Townsville Port operates a Water Polishing Plant for the treatment of site stored water. The Water Polishing Plant Filtration system requires regular maintenance in order to replace Filtration Rods. With the Filter Bank maintenance ports being at a level that cannot be accessed from ground level, it was necessary to arrange work platforms to perform this maintenance.

Read moreYokogawa DCS Upgrade

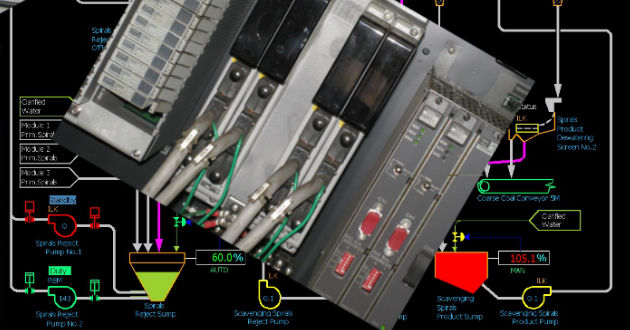

Since 2005, Orana Engineering has provided 24/7 support for Oaky Creek Coal control systems. At the coal handling and preparation plant, a Yokogawa DCS installed in 1998, is used as the primary control system. With existing CentumCS Unix software no longer supported by Yokogawa, it was essential to complete an upgrade to the CentumCS3000 system. Orana Engineering developed conversion tools to allow configuration data to be extracted from the CentumCS Unix platform and imported into the CentumCS3000 environment. These tools provided efficiency and accuracy for the conversion and delivered a significant cost saving. The quality of conversion tools and simulation programs developed by Orana Engineering resulted in highly efficient site commissioning, completed without plant downtime.

Read more