Engineering at Coal Mines

Queensland has a rich and vast deposit of high-quality coal resources with over 34 billion tonnes of raw coal having been identified. It boasts a combination of thermal coal for power generation and over 8 billion tonnes of coking coal suitable for high quality steel milling (from Dept. of Natural Resources and Mines). Coal is extracted from the ground using both open-cut and underground mining operations and is then typically subject to further processing at Coal Handling and Processing Plants (CHPP) before being transported via conveyor, truck, rail or ship (or combination of these) to the buyer.

Orana Engineering has built a strong reputation within the coal industry, offering electrical, mechanical, structural and control systems engineering support to a wide range of clients spread throughout the Bowen and Surat basins. Our Townsville, Chinchilla and Mackay offices are placed to offer local support for operations based in the Bowen and Surat Basins and to support the expansion of the coal industry into the Galilee Basin.

Our engineering services including design, project management, design drafting, revisions and drawing management are intended to support the fixed plant and surface infrastructure of mining operations including the CHPP and associated services such as onsite water treatment plants. We also support the underground coal mining operations providing conveyor installation designs and mine dewatering designs. As the industry is governed by specific legislation including the Coal Mining Safety and Health Act and Regulation, it is important that engineering consultants are fluent with these regulations, which Orana Engineering is. Further information on the Act and Regulations can be found here.

Coal Mining Safety and Health Act 1999

Coal Mining Safety and Health Regulation 2017

Our engineering experience and expertise within the coal industry gives our personnel a first-hand understanding of the process and site practicalities. Explore the case studies below to see the services that we have offered to our clients in the coal sector.

Orana Engineering Coal Mining Engineering

Underground Workshop Concept Design

Due to expanding operations, Oaky North underground operations saw benefit in having an underground workshop and refuelling stations to reduce vehicle travel times and increase efficiencies. Orana Engineering was engaged to provide concept design and estimating assistance for project approval. From communications with our client, Orana Engineering prepared concept general arrangement drawings for consideration. Based on these concept design drawings, a project capital estimate and project schedule were prepared for Oaky North underground operations. From the information presented by Orana Engineering, Oaky North could accurately consider whether the underground workshop was feasible, and ensure that appropriate budgets and project planning was completed at the concept design phase to improve confidence in the project prior to execution.

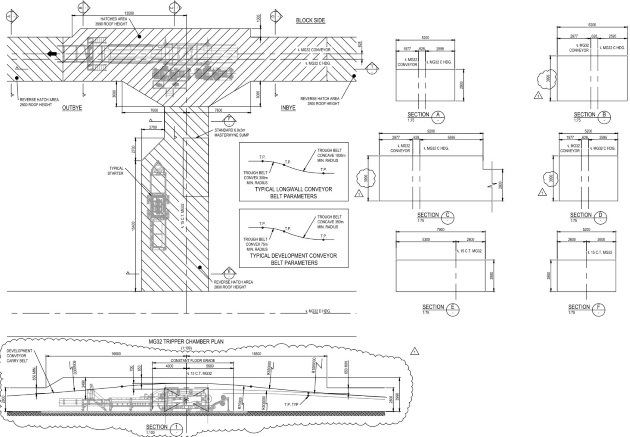

Read moreUG Conveyor Installations – MG32 Tripper Chamber

Maingate roadways mined to accommodate longwall conveyors at Glencore’s Oaky No. 1 underground coal mine can vary from a few hundred meters to over 4 kilometres in length. Transporting vast quantities of coal over long distances requires a significant amount of power. In some cases the drive-head power is insufficient or is constrained by the allowable belt tension and an additional drive / power source is required to meet the required operating capacity. Commonly this additional power will come in the form of a driven conveyor tripper installed at a nominal point along the conveyor, which requires the appropriate excavation for the tripper installation inclusive of drives, tripper frame, braking and belt starter.

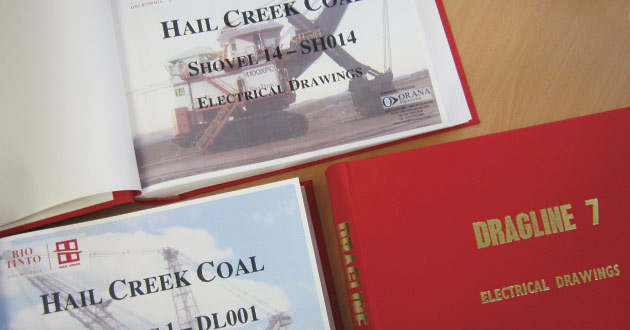

Read moreMobile Plant Electrical Drawing Books

For personnel safety and compliance with Queensland’s Coal Mining Safety & Health Regulation it is a requirement for mine sites to provide electrical workers with access to up-to-date drawings for electrical equipment and electrical installations. To improve the maintainability of plant electrical systems and personnel safety, Hail Creek Mine engaged Orana Engineering to create bound books of electrical drawings for Draglines 1 and 7 and Shovel 14. Multiple books were made for each machine in both A4 and A3 sizes and using waxed (water proof) paper to ensure longevity. Using vendor drawings from the client, Orana Engineering produced bound books containing all electrical power, control and termination diagrams associated with the respective mobile plant.

Read moreConveyor Upgrade Project

Carborough Downs Coal underground mine had transitioned from a bord and pillar mining system to longwall. The result was a need to upgrade capacity of the coal clearance conveyor system. Orana Engineering was engaged to provide Client Engineering assistance to deliver underground conveyor equipment to meet the longwall production schedule. Orana Engineering monitored vendor design progress against the schedule, performed design reviews to ensure correction of errors prior to final client approval, monitored and managed fabrication and delivery schedules and managed budget and variations in line with the contract. By co-ordinating with the client’s installation group and managing the vendor in line with the client’s schedule, the conveyors were successfully installed and made available for longwall production.

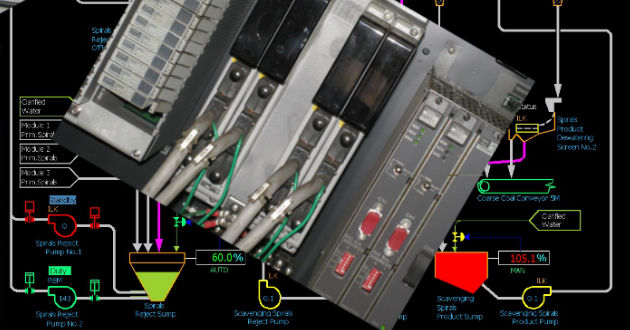

Read moreYokogawa DCS Upgrade

Since 2005, Orana Engineering has provided 24/7 support for Oaky Creek Coal control systems. At the coal handling and preparation plant, a Yokogawa DCS installed in 1998, is used as the primary control system. With existing CentumCS Unix software no longer supported by Yokogawa, it was essential to complete an upgrade to the CentumCS3000 system. Orana Engineering developed conversion tools to allow configuration data to be extracted from the CentumCS Unix platform and imported into the CentumCS3000 environment. These tools provided efficiency and accuracy for the conversion and delivered a significant cost saving. The quality of conversion tools and simulation programs developed by Orana Engineering resulted in highly efficient site commissioning, completed without plant downtime.

Read more