TC04 Trunk Conveyor Extensions

Carborough Downs Coal Mine is an underground operation located in Central Queensland that utilises conveyors to transport mined raw material to the surface for processing. As operations progress and new maingate headings are mined, trunk conveyor extensions are required.

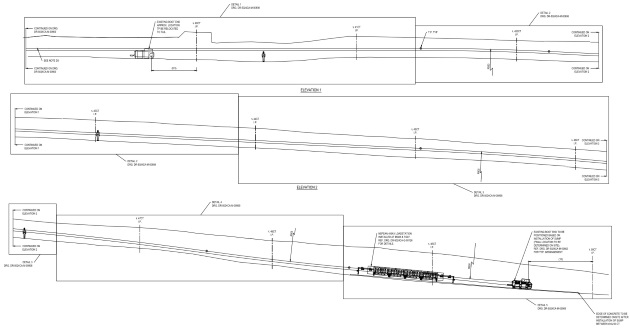

Carborough Downs engaged Orana Engineering to assist with the process of extending one of their underground trunk conveyors. This involved using survey data of the “as mined” conveyor heading and designing a suitable belt profile, utilising the minimum conveyor curves identified in the conveyor power and tension analysis. The belt profile design had to consider a number of constraints, including minimum bending radii for the belt, allowance for future maingate load stations, and vehicle underpass points. Orana Engineering uses a unique method for laying out conveyor structure and extracting set-out data using Microsoft Excel, to enable quick and efficient tabulation of conveyor structure data within our drawings.

Orana Engineering produced a set of drawings detailing the belt profile, conveyor structures required and locations for the roof bolts that the structures would be suspended from, with appropriate installation data provided, including RL, chainage and bolt centreline offset dimensions.

These drawings enabled the site engineers to efficiently complete the conveyor structure installation and conveyor extension with minimal risk of installation error and associated conveyor tracking problems.

If you would like any more information or details about Orana Engineering’s design drafting services, please do not hesitate to contact us or review our capabilities.