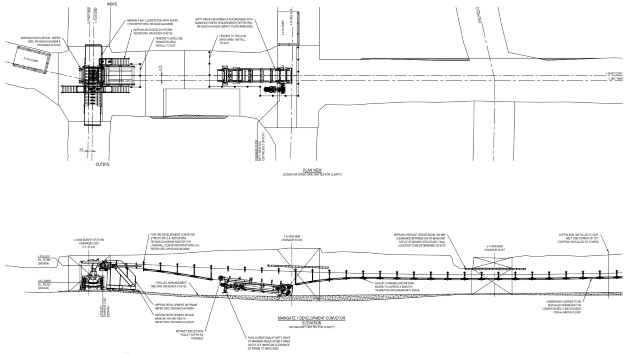

MG07 Conveyor – Development Conveyor

Carborough Downs Coal Mine is an underground operation located in Central Queensland that utilises conveyors to transport mined coal to the surface for processing. As operations progress and new longwall headings are mined, new conveyor installations are also required. Designing a conveyor installation involves 3 major stages: the drive-head chamber design, the civil design, and the mechanical arrangement design.

Due to the varying requirements of each conveyor installation, developing a mechanical arrangement design for the configuration of the conveyor equipment is vital for a successful conveyor installation. Orana Engineering was engaged by Carborough Downs to complete this design. On completion of the drive-head chamber mining, Orana Engineering was provided with “As-Cut” survey data which was used to determine the general grade and shape of the chamber. The mechanical design had to consider a number of factors, including meeting the required operating capabilities, allowing for unimpeded access along any travel roads in the area, and maintaining minimum belt curves (conveyor structure layout).

Orana Engineering used AutoCAD to develop a mechanical design that worked within the required parameters and met the client’s constructability requirements. From this design, Orana Engineering produced a drawing set that detailed out the mechanical aspects of the conveyor design, including equipment configurations and extensive details for the selection and installation of the conveyor structures whilst meeting minimum curve requirements.

If you would like any more information or details about Orana Engineering’s design drafting or engineering services, please do not hesitate to contact us or review our capabilities.