Engineering Maintenance & Support

Engineering maintenance and support is an essential service over the life of an operation and includes scheduled maintenance services as well as support for breakdowns and failures. We follow a logical fault finding process to identify the root cause and where applicable provide recommendations to reduce the likelihood and/or consequences of the event occurring again.

Through our engineering maintenance and support services, Orana Engineering strives to build long term relationships with our clients. Building long term relationships is an integral part of our business model and business philosophy and it gives us the best opportunity to be a resource that is valued by our clients. We believe that this value comes, over time, from better knowing our clients' sites, systems and people. From this knowledge we can provide engineering services that are tailored to our clients' requirements.

Our engineering support services include control systems support, training and commissioning as well as client engineer services. We provide engineering maintenance and support for coal, metalliferous, oil and gas clients as well as industrial and commercial clients.

Explore the case studies below for more information on maintenance and support services by Orana Engineering.

Orana Engineering Maintenance & Support

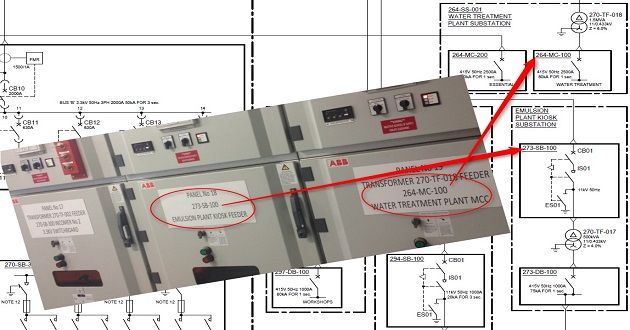

Redraw Electrical Drawings

To ensure plant maintainability and personnel safety, Dyno Nobel employed Orana Engineering to redraw its low voltage and high voltage single line diagrams, while also confirming their accuracy and functionality. Through the use of client photos, documentation and discussions Orana Engineering was able to accurately redraw 52 low voltage single line diagrams as well as 6 high voltage single line diagrams. During the redraw process Orana Engineering identified that a larger size drawing template was required to ensure critical information was easily readable on a single drawing. An A0 size drawing template was designed to meet Dyno Nobel's drawing standards with the template providing links for the document management system to easily access drawing metadata.

Read moreSewage Treatment Plant Refurbishment

To increase productivity and maintain compliance with legislative standards, Glencore Coal employed the services of Orana Engineering to design and manage the electrical aspects of an upgrade to their existing sewage treatment plant. The project was managed on-site by others, with Orana Engineering providing electrical engineering, design, project management and construction / commissioning assistance. Upon completion of installation, Orana Engineering updated all drawings to reflect any changes made, thus providing Glencore Coal with as-built drawings which will make any future maintenance or fault-finding work more efficient and cost effective, as well as providing legislative compliance.

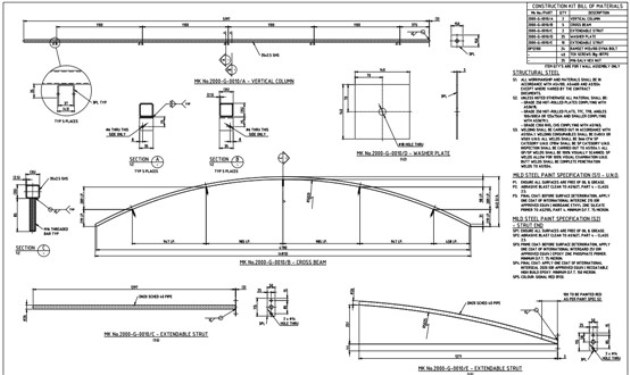

Read moreTank Static Line

Management at Carpentaria Gold’s Ravenswood Operation enlisted Orana Engineering to design a fall arrest system that could be easily removed and repositioned above multiple leach tanks, allowing for safe removal and servicing of tank agitators. From a site visit, Orana Engineering identified the need for an arrangement that could be easily disassembled and relocated to each leach tank. The design was challenging due to the varying nature of access structure members above tanks. Orana Engineering designers proposed an assembly utilising a common set of supporting columns with struts of varying lengths depending on the work location. A full set of shop fabrication and assembly drawings were issued with the final design providing safety for personnel working above open tanks.

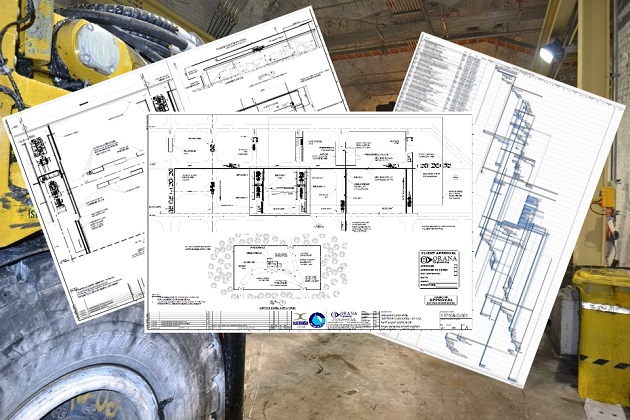

Read moreUnderground Workshop Concept Design

Due to expanding operations, Oaky North underground operations saw benefit in having an underground workshop and refuelling stations to reduce vehicle travel times and increase efficiencies. Orana Engineering was engaged to provide concept design and estimating assistance for project approval. From communications with our client, Orana Engineering prepared concept general arrangement drawings for consideration. Based on these concept design drawings, a project capital estimate and project schedule were prepared for Oaky North underground operations. From the information presented by Orana Engineering, Oaky North could accurately consider whether the underground workshop was feasible, and ensure that appropriate budgets and project planning was completed at the concept design phase to improve confidence in the project prior to execution.

Read moreWall Kit Drafting

BHP Billiton Cannington Mine is a significant underground silver and lead mining operation in Western Queensland. Following completion of ore extraction from each stope, paste backfill is used to fill the open void and stabilise the area. This is achieved by constructing a fill wall which provides stability for areas being back filled, eliminates intrusion, and allows a higher density of back fill. Wall constructions kits supplied to Cannington contained no documentation detailing the kit components. BHP Billiton engaged Orana Engineering to confirm the components in these kits. Using measurements and sketches obtained from site, Orana Engineering design drafting personnel utilised AutoCAD to create a drawing set detailing the components required and fabrication details for each construction kit.

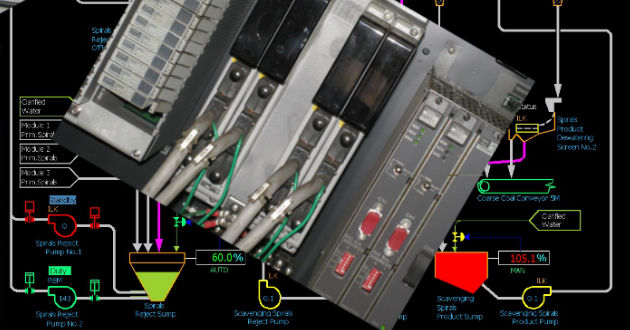

Read moreYokogawa DCS Upgrade

Since 2005, Orana Engineering has provided 24/7 support for Oaky Creek Coal control systems. At the coal handling and preparation plant, a Yokogawa DCS installed in 1998, is used as the primary control system. With existing CentumCS Unix software no longer supported by Yokogawa, it was essential to complete an upgrade to the CentumCS3000 system. Orana Engineering developed conversion tools to allow configuration data to be extracted from the CentumCS Unix platform and imported into the CentumCS3000 environment. These tools provided efficiency and accuracy for the conversion and delivered a significant cost saving. The quality of conversion tools and simulation programs developed by Orana Engineering resulted in highly efficient site commissioning, completed without plant downtime.

Read more