Engineering Services

Orana Engineering offers a complete range of engineering services and design drafting services through the in-house expertise of our qualified and experienced team. As an engineering consultancy working in mechanical, electrical, structural and control systems engineering, Orana Engineering is experienced in detailed design engineering for the coal mining, metalliferous mining, oil and gas and heavy industries.

Orana Engineering's engineering services include, but are not limited to the preparation and delivery of:

- Budget Estimates;

- Detailed Engineering Designs and Calculations;

- Engineering Investigations and Audits;

- Engineering Specifications;

- Engineering Studies;

- Functional Descriptions;

- Hazardous Area Designs;

- Project Management;

- Project Scheduling;

- Scopes of Works;

- System Modelling;

- Tailored Control System Training Courses; and

- Technical Evaluations.

For projects consisting of civil engineering design, Orana Engineering has the resources to fulfill the project's requirements via in-house expertise and established and proven relationships with external companies.

Our people are core to the quality of engineering services offered and our team is both technically qualified and practically experienced. Our staff possess RPEQ certifications, CPEng qualifications and hands-on site backgrounds. We deliver a unique approach to engineering services and engineering design. Having operations and maintenance engineering backgrounds, the experience of Orana Engineering personnel make them better able to understand the complexities and scheduling challenges that are often involved in performing engineering activities for continuous and remote operations. This results in a more cost and time efficient solution for the client.

The unique combination of our experience, wide-ranging capabilities and practical approach ensures Orana Engineering delivers engineering services that:

- Perform - Site experience and trade backgrounds mean our engineering designs are practical and considerate of site factors that can complicate a project, our designs are not just good on paper;

- Are simple - Our clients have access to a full range of engineering services under one roof, building a relationship with one engineering firm that can manage everything from your design drafting, drawing revisions and drawing management through to complete project management or Client Engineer assistance;

- Instill confidence - Working with an experienced firm gives our clients confidence and allows them to be informed to make decisions; and

- Are efficient - Outsourcing engineering services can assist with site resourcing, freeing up site personnel and ensuring that you have a qualified expert dedicating the right amount of time to the required task.

Contact us today to see how Orana Engineering’s qualified and experienced personnel can add value to all your engineering service requirements.

Orana Engineering Design Drafting

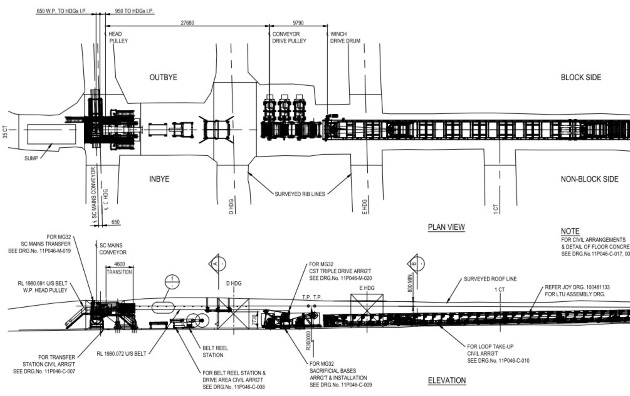

UG Conveyor Installations - MG Mechanical Installation

Detailing the installation of mechanical equipment and conveyor structures is one of the final steps for completing a maingate drive-head design. Installations designed by Orana Engineering for Glencore’s Oaky No.1 underground coal mine included detailing drive arrangements, transfer stations, take-up units, maintenance equipment and the overhead structures supporting the carry belt. Mechanical design must consider a number of factors, including meeting the required operating capabilities, allowing for unimpeded access along travel roads, and maintaining minimum belt curves. Often equipment is relocated from previous installations with minor modifications in transfer angle and number of drives. Orana Engineering has developed unique methods for completing this type of design, enabling us to keep total costs down for our clients.

Read moreCombabula Bore Pump

Prime Pump Company was contracted by Origin Energy and Laing O’Rourke to supply an upgraded bore pumping system at Origin’s Combabula site. RIE Services was contracted by Prime Pump Company to supply and install electrical components for the upgrade, with Orana Engineering subsequently engaged by RIE Services to complete a fault protection study on the new installation. Using SKM Power Tools for Windows software and manual calculation techniques for verification, together with information from RIE and Prime Pump Company, Orana Engineering produced an HV/LV model calculating fault levels and completing a protection co-ordination study. From the study it was recommended a new circuit breaker be introduced to protect the transformer, variable speed drive and supply cables.

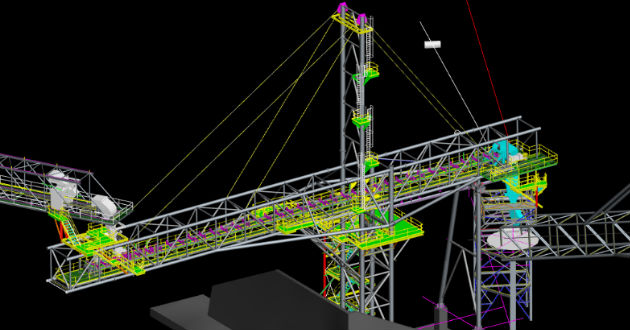

Read more22M Flyover Conveyor

Oaky Creek Coal engaged Orana Engineering to perform electrical and control system design aspects of a 22M Flyover Conveyor to provide an interface between two existing conveyor systems. Orana Engineering’s brownfield engineering expertise was drawn upon to resolve complexities in interfacing two different coal streams, powered from separate substations and controlled from independent process control systems. Should one system need to be shutdown it was necessary that the other system was not impacted. The electrical engineering scope included powering the conveyor and transfer systems and providing lighting designs and power distribution. Control system engineering included selection and specification of instrumentation, specification of control system hardware and development of a functional specification.

Read moreBall Mill No. 2 Recommissioning

FMR Investment's Eloise Copper Mine had a requirement to recommission their No.2 Ball Mill. During the process of the recommissioning works it was identified that a means to relocate the grinding media to the feed chute needed to be designed and engineered with RPEQ certification.

Read moreCHPP Conveyor Capacity Audit

Vale at Carborough Downs Coal Mine required quantifying of current and possible future capacities of product conveyors at their coal processing plant in Central Queensland and high level recommendations to achieve increased plant tonnages. Orana Engineering completed an initial site visit to gather the necessary information for review of each of the conveyors. Engineering checks were completed to identify ‘bottle-necks’ in the conveyor design such as motor power, drive equipment, belt curves, GTU mass, belt speed, belt capacity, belt tensions and electrical supply. Orana Engineering issued a detailed report at completion of the study and provided concept level equipment modification recommendations for tonnage ranges advised by Carborough Downs Coal Mine.

Read moreCrusher Circuit Upgrade

Eloise Copper Mine purchased a Metso dual deck vibrating screen to replace an existing smaller screen and a second Omnicone cone crusher to provide a secondary crushing circuit for increased production and efficiency. Orana Engineering was engaged to develop a design solution and detailed drawings for the secondary crushing circuit which utilised as much existing equipment as possible. Orana Engineering was able to provide an efficient, practical design solution while minimising the associated design costs to provide site personnel with information required to refurbish and install the conveyor equipment necessary for the crushing circuit. Orana Engineering successfully completed the design within a tight project time frame and produced in excess of 100 detailed drawings.

Read moreCyanide Tank Upgrade

Carpentaria Gold identified that bunding around their Ravenswood cyanide storage tank was inadequate. Sodium Cyanide, used in the gold recovery process, is potentially lethal to humans and animals and detrimental to the environment. It is necessary to ensure it can be safely contained in an emergency. Orana Engineering provided an innovative solution comprising a smaller tank fitted inside the existing tank. The design minimised loss of storage capacity by providing a smaller tank for primary storage whilst maintaining the existing external tank to act as the bund. Utilising the existing tank as a bund, Orana Engineering delivered a design that met the client brief while re-using the majority of major tie-in points and providing improved access for maintenance.

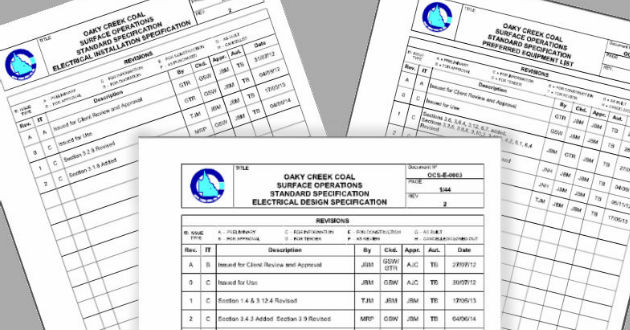

Read moreElectrical Specifications

For site consistency of electrical design and installation standards and compliance with Australian standards and legislation, Glencore Oaky Creek Coal engaged Orana Engineering to prepare new site electrical specifications. The scope combined existing site specifications and practices and, where applicable, incorporated them into the new specifications. These specifications included:

- Electrical Design

- Electrical Installation

- Preferred Electrical Equipment List

- Site Equipment Numbering

- Drawing Management

Orana Engineering’s extensive knowledge of Queensland mine sites and long-standing experience at Oaky Creek enabled specifications to be produced cost effectively and fully inclusive of site specific details. Orana Engineering continues to maintain these documents for Oaky Creek Coal, ensuring that latest versions are readily available to site personnel via Oaky Creek’s drawing management system.

Read moreFB-028 Tank Lifting Beam

During an upgrade to the Concentrator at MMG’s Century Mine located in Western Queensland, Orana Engineering was engaged to design a lifting beam for the installation of a new flotation cell.

Read moreFire System Audit

BMA Gregory Crinum engaged Orana Engineering to perform an audit and inspection of the Crinum underground mine surface fire water system with respect to providing adequate pressure and flow for the Crinum North conveyor system and stockpile conveyor. Orana Engineering completed a site inspection and audit against the design drawings, with site-verified information then used for compliance assessment in line with Australian Standards. The audit included in-depth assessment of the fire water system to Australian, BMA and site Fire Management Standards. Hydraulic modelling of the fire system was also undertaken to validate existing pressure measurements. Orana Engineering was able to make recommendations regarding compliance and system hydraulic performance, which assisted BMA in improving system capacity.

Read more