Control Systems Engineering

Control Systems Engineering involves using computer processors to automate and monitor the operation of processes, equipment and machinery. A control system accepts data from the field (e.g. a tank’s level) or from an operator (via an HMI (Human Machine Interface)) and based on the logic configuration (i.e. algorithm) configured by the Control Systems Engineer, the control system may execute an action (e.g. such as starting up a pump to drain the tank). Control systems also assist the operator by continuously monitoring the operation and bringing to the operators attention information that requires action. Control systems also capture historical data, providing valuable plant data which may be used for fault finding or assessing plant productivity and efficiencies.

Orana Engineering specialises in Control Systems Engineering with broad experience including PLC (Programmable Logic Controller) and SCADA (Supervisory Control and Data Acquisition) configurations through to configuration of DCS (Distributed Control System) for larger scale operations. We design, test, commission and improve control systems for coal, metalliferous, oil and gas clients as well as industrial and commercial clients.

Our control system configurations focus on:

- Providing full diagnostics, so operators don’t need to look for the problem, it is brought to their attention;

- Capturing historical data, essential for fault finding and benchmarking for operational improvements;

- Consistency, so it is easier for operations and maintenance personnel to become familiar with how to operate and maintain the system; and

- Modular programming, so the system is adaptable to operational changes.

Explore the case studies below for more information on Control Systems Engineering by Orana Engineering.

Orana Engineering Control Systems

10M TAGS Sled

At James Cook University, MBD Energy operates a research facility investigating methods of cultivating and harvesting algae. To facilitate greater control of the algae agitation sleds, Orana Engineering was engaged to design and commission mechanical, electrical and control systems that would enable agitation sled velocity and frequency of travel to be automated. The system was designed and implemented by Orana Engineering utilising Allen Bradley Powerflex VVVF drives and a Controllogix’s PLC with an RSView SCADA interface. Orana Engineering was able to help MBD Energy improve the efficiency and quality of their research results by providing technical knowledge and assistance through our control systems, electrical engineering and mechanical engineering services.

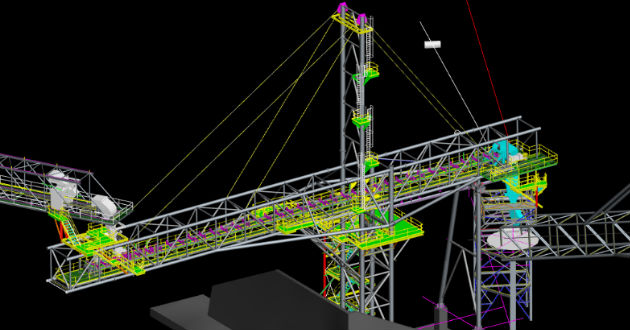

Read more22M Flyover Conveyor

Oaky Creek Coal engaged Orana Engineering to perform electrical and control system design aspects of a 22M Flyover Conveyor to provide an interface between two existing conveyor systems. Orana Engineering’s brownfield engineering expertise was drawn upon to resolve complexities in interfacing two different coal streams, powered from separate substations and controlled from independent process control systems. Should one system need to be shutdown it was necessary that the other system was not impacted. The electrical engineering scope included powering the conveyor and transfer systems and providing lighting designs and power distribution. Control system engineering included selection and specification of instrumentation, specification of control system hardware and development of a functional specification.

Read moreMIBC & Diesel Upgrade

The purpose of the Reagent System Upgrade at Oaky Creek was installation of new reagent storage tanks, discharge / delivery pumping systems and automated flow control distribution manifolds for the delivery of each reagent to the nominated process connections. Orana Engineering performed mechanical, electrical and control systems design, drafting and engineering for the project. The primary deliverables included scope of works, construction drawings, functional specification, BOM, spares lists and equipment / instrument data sheets. Orana Engineering managed the onsite commissioning of the system and provided a system handover to operations for implementation. An Operation & Maintenance Manual and Hazardous Area Dossier were provided on project completion.

Read moreOnsite Accommodation Camp Services

Orana Engineering was engaged by Oaky Creek Coal to assist in design and construction of onsite camp accommodation, including an HV substation for power and potable water supply. Our brief included mechanical, electrical and control systems design, drafting and engineering for the project. Deliverables included scope of works, construction drawings, functional specification, drawing and equipment registers, commissioning and operating spares lists and equipment and instrument data sheets. Orana Engineering provided PLC configuration and commissioning assistance for pump control, acted as Client Representative during construction, managed onsite commissioning of the system, and provided a handover to operations for implementation. Operation & Maintenance Manuals for potable water storage and the HV substation were provided upon completion.

Read moreSewage Treatment Plant Refurbishment

To increase productivity and maintain compliance with legislative standards, Glencore Coal employed the services of Orana Engineering to design and manage the electrical aspects of an upgrade to their existing sewage treatment plant. The project was managed on-site by others, with Orana Engineering providing electrical engineering, design, project management and construction / commissioning assistance. Upon completion of installation, Orana Engineering updated all drawings to reflect any changes made, thus providing Glencore Coal with as-built drawings which will make any future maintenance or fault-finding work more efficient and cost effective, as well as providing legislative compliance.

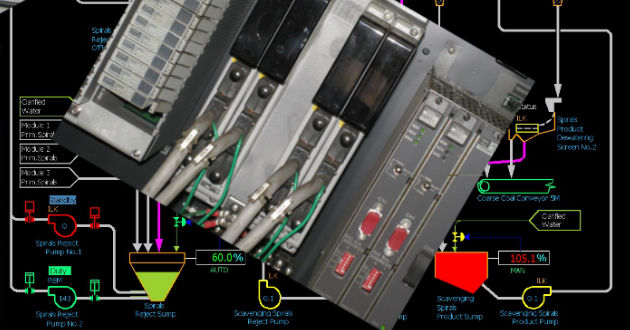

Read moreSite DCS Support

The Coal Handling & Preparation Plant at Oaky Creek Coal utilises a Yokogawa Distributed Control System for control and monitoring of their operation. The system incorporates Yokogawa’s OPC server and Exaquantum data historian. OCC utilises multiple Programmable Logic Controllers for specific operational purposes, with a number of PLCs interfaced back to the DCS for control and monitoring functions. Since 2005, Orana Engineering has provided 24/7 support for Oaky Creek’s control system. Day to day support is provided by remote access, which is cost effective and highly responsive. Additionally, onsite support for hardware solutions and commissioning of larger projects is provided as required.

Read moreYokogawa DCS Upgrade

Since 2005, Orana Engineering has provided 24/7 support for Oaky Creek Coal control systems. At the coal handling and preparation plant, a Yokogawa DCS installed in 1998, is used as the primary control system. With existing CentumCS Unix software no longer supported by Yokogawa, it was essential to complete an upgrade to the CentumCS3000 system. Orana Engineering developed conversion tools to allow configuration data to be extracted from the CentumCS Unix platform and imported into the CentumCS3000 environment. These tools provided efficiency and accuracy for the conversion and delivered a significant cost saving. The quality of conversion tools and simulation programs developed by Orana Engineering resulted in highly efficient site commissioning, completed without plant downtime.

Read more